Industrial gearboxes play a crucial role in power transmission in a wide range of industries. These complex machines are responsible for transferring power from a motor to a driven load and are often subjected to heavy loads and harsh operating conditions. Proper maintenance is essential to ensure an industrial gearbox operates at peak performance and has a long lifespan. Today, we will discuss the key components of an industrial gearbox and the maintenance requirements for keeping it in good working order. Let us also explore the importance of choosing a reputable industrial gearbox supplier offering high-quality power transmission products and working closely with gearbox manufacturers to provide expert maintenance and support. By the end, we will have a deeper understanding of the importance of industrial gearbox maintenance and how working with a trusted supplier can help ensure your gearbox operates reliably and efficiently.

Key Components of an Industrial Gearbox

An industrial gearbox is a complex machine consisting of several key components that work together to transfer power from a motor to a driven load. Each component plays a critical role in the proper operation of the gearbox, and any malfunction or wear can cause significant damage to the machine. The following are the key components of an industrial gearbox:

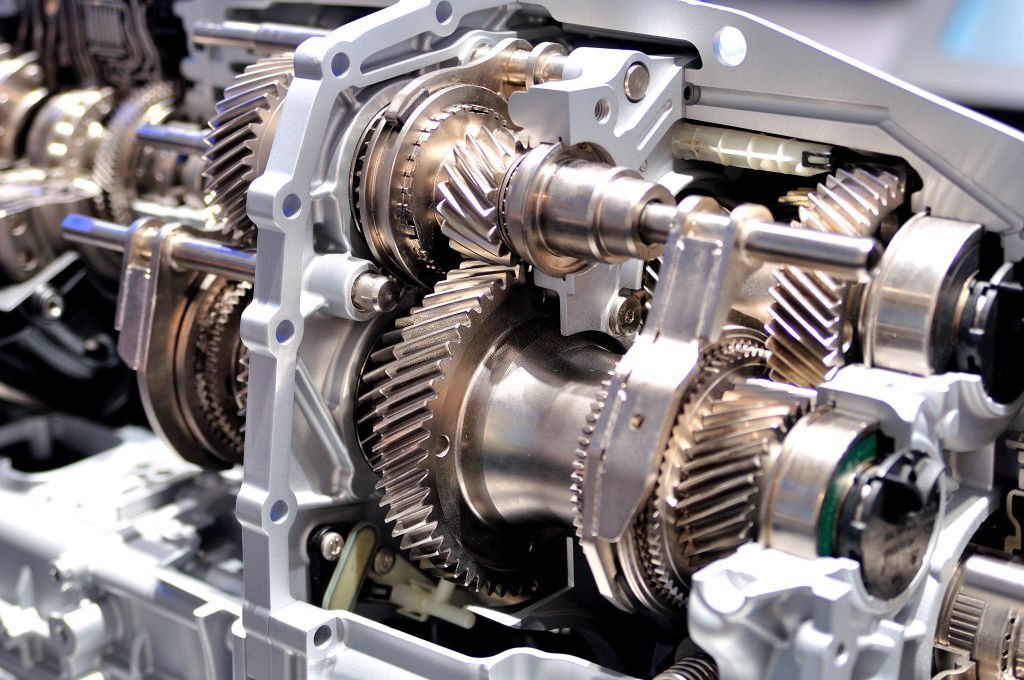

1. Gears

Gears are the most critical component of an industrial gearbox. They are responsible for transmitting torque and power from the input shaft to the output shaft. There are several types of gear used in industrial gearboxes, including spur, helical, bevel, and worm gears. The type of gear used depends on the application and operating conditions.

2. Bearings

Bearings are used to support the rotating shafts of the gearbox and reduce friction between the shaft and the housing. They are essential in reducing wear and tear of the gearbox components and ensuring smooth operation.

3. Seals

Seals are used to prevent lubricant leakage and contamination from entering the gearbox. They play a critical role in protecting the gearbox from dirt, debris, and other contaminants.

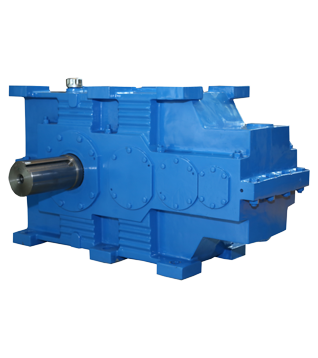

4. Housing

The gearbox housing contains all the components of the gearbox, including the gears, bearings, seals, and lubricant. It protects the internal components from external damage and provides structural support.

5. Lubrication system

Proper lubrication is crucial in ensuring the smooth operation of the gearbox. The lubrication system distributes oil or grease to the gearbox components to reduce friction, prevent wear and tear, and dissipate heat.

Each component of the gearbox plays a crucial role in its proper operation, and any malfunction or wear can cause significant damage to the machine. It is essential to conduct regular maintenance and inspection of these components to ensure the gearbox operates at peak performance and has a long lifespan.

Maintenance Requirements for Industrial Gearboxes

Proper maintenance of an industrial gearbox is crucial in ensuring it operates efficiently and has a long lifespan. The following are the key maintenance requirements for industrial gearboxes:

1. Regular Inspection And Cleaning Of The Gearbox

Regular inspection and cleaning of the gearbox can help identify potential problems before they become major issues. Inspecting the gearbox for signs of wear, cracks, or leaks can help prevent costly repairs or downtime. Cleaning the gearbox can help remove dirt, debris, and other contaminants that can cause damage to the gearbox components.

2. Lubrication And Oil Changes

Proper lubrication is essential in ensuring the smooth operation of the gearbox. Over time, the lubricant can become contaminated with dirt, debris, or water, reducing its effectiveness. Regular oil changes can help prevent wear and tear of the gearbox components and ensure they are adequately lubricated.

3. Proper Alignment Of The Gearbox

Improper alignment can cause excessive wear and tear on the gearbox components and lead to premature failure. Proper alignment of the gearbox can help ensure it operates smoothly and reduces stress on the gears, bearings, and seals.

4. Monitoring Of Vibration Levels

Excessive vibration can cause damage to the gearbox components and lead to premature failure. Monitoring vibration levels can help identify any potential problems and allow for corrective action before major damage occurs.

5. Replacement Of Worn Or Damaged Parts

Worn or damaged parts can cause significant damage to the gearbox and reduce its efficiency. Regular inspection and replacement of worn or damaged parts can help prevent major damage to the gearbox and reduce downtime.

Choosing the Right Industrial Gearbox Supplier

Choosing the right industrial gearbox supplier is crucial in ensuring your gearbox’s efficient and long-term operation. The following are some factors to consider when selecting an industrial gearbox supplier:

1. Reputation

Choosing a reputable supplier with a proven track record of providing high-quality power transmission products and excellent customer service is essential. Look for reviews and testimonials from previous customers to get an idea of their experience working with the supplier.

2. Expertise

Choose a supplier with expertise in the industry and a thorough understanding of industrial gearboxes. They should be knowledgeable about different gearbox types, their applications, and maintenance requirements.

3. Range of Products

A good supplier should have a wide range of power transmission products, including different gearbox types, to ensure you find the right product that suits your needs.

4. Technical Support And Maintenance

The supplier should offer technical support and maintenance services, including installation, inspection, and repair of the gearbox. They should have a team of skilled technicians who can provide expert advice and assistance.

5. Cost-effectiveness

Choose a supplier that offers competitive pricing without compromising the quality of their products and services.

What Questions Should You Ask When Choosing An Industrial Gearbox Supplier?

-

What types of industrial gearboxes do you supply?

At our company, we take pride in supplying a comprehensive range of industrial gearboxes to cater to diverse industry needs. Our extensive product lineup includes high-quality gearboxes such as helical, worm, planetary, and parallel shaft gearboxes.

-

Do you offer technical support and maintenance services?

Absolutely! We believe in providing exceptional customer service beyond just supplying gearboxes. Our commitment extends to offering comprehensive technical support to ensure optimal performance and longevity of our gearboxes.

-

What is your experience in the industry, and how long have you been in business?

With a solid track record of over 35 years in the industry, we have established ourselves as a reliable and experienced supplier. Over the years, we have successfully completed numerous projects, collaborated with a wide range of clients, and continuously adapted to the evolving needs of the industrial market.

-

Can you provide references or testimonials from previous customers?

We are more than happy to provide you with references and testimonials from our satisfied customers who have experienced the quality of our gearboxes and exceptional service. It will give you valuable insights into their firsthand experiences, highlighting the reliability, durability, and performance of our gearboxes and the support they received from our team.

-

What is your pricing structure, and are there any additional costs?

We strive to offer value for money to our customers without compromising on quality. When you choose our gearboxes, you can be confident that our prices are reflective of the superior craftsmanship and reliability that we uphold. We believe in providing upfront pricing, ensuring that there are no hidden costs or surprises along the way. However, since pricing can vary based on specific requirements, we encourage you to reach out to us for a personalised quote.

Where To Find The Best Industrial Gearbox Suppliers In India?

Are you searching for high-quality industrial gearbox suppliers in India? Then look no further than Santram Engineer PVT. LTD. Their decades of experience and inventive and innovative solutions to all your industrial necessities have set them apart and made them the leading supplier of industrial gearboxes. Have a look at Santram Engineer PVT. LTD and its vast product catalog comprise industrial power transmission products, industrial gearboxes, electric motors, and much more. To know more, contact us at +91 96247 39393 or drop us a mail at sales@santramengineers.com.