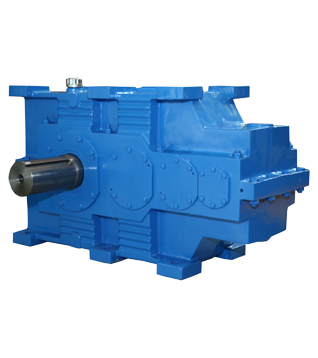

Worm gearboxes are essential in many industries, including automotive, manufacturing, and mining. They are used to transfer power between two non-parallel shafts and are characterized by their high torque capacity, compact design, and low noise level. As one of India’s leading worm reduction gearbox dealers, we discuss the key things to take care of in the maintenance of worm gearboxes.

What is a Worm Gearbox?

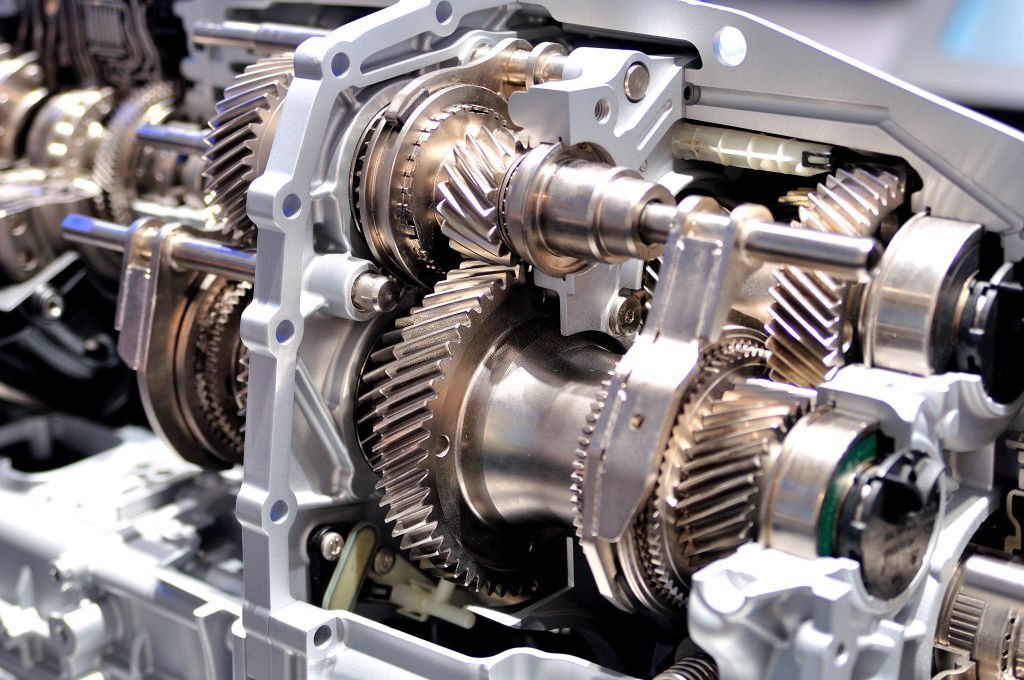

A worm gearbox is a mechanical device consisting of a worm gear and a worm wheel. The gear is a screw that links with the teeth of the wheel. The worm gear is the input, while the worm wheel is the output. The input shaft of the gearbox is attached to the worm gear, while the output shaft is attached to the worm wheel.

How Does a Worm Gearbox Work?

The operation of a worm gearbox is relatively simple. When the worm gear is rotated, it rotates the worm wheel, which rotates the output shaft. The rotation of the worm gear causes the worm wheel to rotate in the opposite direction. The ratio of the number of teeth on the worm gear to the number of teeth on the worm wheel determines the gear ratio of the gearbox. This ratio can be as high as 100:1, making worm gearboxes ideal for high-torque applications.

Crucial Factors to Consider for Worm Gearbox Maintenance

Lubrication

Lubrication is one of the most critical factors in the maintenance of worm gearboxes. It helps to reduce friction and wear between the worm gear and the worm wheel. Proper lubrication can help extend the lifespan of the gearbox and improve its performance. The type of lubricant used should be appropriate for the operating conditions and the gearbox design.

Inspection

Regular inspection of worm gearboxes is necessary to detect any signs of wear or damage. This can help to identify problems before they become severe and result in costly downtime. The inspection should include checking the teeth of the worm gear and the worm wheel, as well as the bearings and seals. Any signs of wear or damage should be addressed promptly to prevent further damage.

Temperature Monitoring

Worm gearboxes generate heat during operation. Excessive heat can cause the lubricant to break down, leading to increased friction and wear. It is essential to monitor the temperature of the gearbox regularly and ensure it remains within the recommended operating range. If the temperature exceeds the recommended range, the gearbox may need to be shut down until the cause of the problem is identified and addressed.

Cleaning

Proper cleaning of worm gearboxes is critical to prevent the buildup of dirt and debris, which can cause increased friction and wear. The gearbox should be cleaned regularly using appropriate cleaning agents and techniques. Care should be taken not to damage any gearbox components during cleaning.

Proper Storage

Proper storage of worm gearboxes is crucial when they are not in use. They should be stored in a dry, cool, and clean environment to prevent corrosion and other forms of damage. Before storing the gearbox, it should be cleaned, inspected, and properly lubricated.

Proper Installation

Proper installation of worm gearboxes is essential to ensure optimal performance and longevity. The gearbox should be installed in accordance with the manufacturer’s recommendations, using appropriate tools and techniques. Care should be taken not to damage any components during installation.

The Right Way to Lubricate Worm Gearboxes

When it comes to lubrication, worm gearboxes have unique requirements due to the sliding action between the worm gear and the worm wheel. The right lubricant can reduce friction and wear, protect against corrosion, and help dissipate heat. However, using the wrong lubricant or applying it incorrectly can lead to accelerated wear, overheating, and even gearbox failure.

Lubrication Challenges

Worm gearboxes face several challenges when it comes to lubrication. One of the most significant challenges is the sliding action between the worm gear and the worm wheel, which can cause the lubricant to break down faster than in other types of gearboxes. The high contact pressure between the two components also requires a lubricant with high film strength to prevent metal-to-metal contact.

Another challenge is the limited space inside the gearbox, which can make it difficult to apply the lubricant correctly. The viscosity of the lubricant must be sufficient to provide adequate lubrication but not so high that it causes increased friction and wear. Additionally, the lubricant must withstand the high temperatures generated during operation without breaking down or oxidizing.

Lubrication Solutions

The right lubricant must be selected based on the specific operating conditions and gearbox design to overcome the challenges of lubricating worm gearboxes. Here are some of the factors to consider when choosing the right lubricant:

The Right Base Oil

Base oil is the foundation of any lubricant, and choosing the right base oil for gearboxes is essential. Mineral oils are commonly used as base oils, but synthetic oils may provide better performance in extreme conditions. Synthetic oils offer improved oxidation resistance, higher film strength, and better low-temperature fluidity.

The Right Additives

Additives are used to enhance the performance of the base oil and provide additional benefits. Anti-wear additives can reduce friction and wear between the worm gear and the worm wheel. Anti-oxidation additives can prevent the lubricant from breaking down at high temperatures, while anti-corrosion additives protect against rust and corrosion.

The Right Viscosity

The viscosity of the lubricant is critical in worm gearboxes. The viscosity must be high enough to provide adequate lubrication but not so high that it causes increased friction and wear. Choosing the right viscosity grade depends on the operating conditions, including the gearbox’s temperature, load, and speed.

The Right Oil Level

The oil level in the gearbox must be maintained at the correct level to ensure proper lubrication. Too much oil can cause foaming and overheating, while too little oil can lead to increased friction and wear. The oil level should be checked regularly and topped up if necessary.

The Right Visual Inspections

Visual inspections of the gearbox can help to detect any signs of wear or damage. The teeth of the worm gear and the worm wheel should be checked for signs of wear or pitting, and any damage should be addressed promptly. The oil level and colour should also be checked regularly to ensure the lubricant performs its job.

The Right Choice

Choosing the right lubricant for worm gearboxes can be challenging, but ensuring optimal performance and longevity is essential. It is recommended to consult with a reputable worm reduction gearbox dealer to determine the best lubricant for your specific application. In addition, following the manufacturer’s recommendations for lubrication and maintenance can help prolong the gearbox’s life and prevent costly downtime.

Does the Efficiency of Worm Gearbox Depend on How You Maintain It?

Yes, the efficiency of worm gearboxes depends on how they are maintained. Proper maintenance, including regular lubrication, visual inspections, and promptly addressing signs of wear or damage, can help ensure optimal performance and longevity. Neglecting maintenance can lead to increased friction, wear, and even gearbox failure, resulting in costly downtime and repairs. Therefore, it is essential to follow the manufacturer’s recommendations for lubrication and maintenance and consult a reputable worm reduction gearbox dealer or industrial gearbox manufacturer for guidance on proper maintenance practices.

Get Premium Quality Worm Gearboxes

If you’re looking for premium quality worm gearboxes, look no further than Santram Engineers. We are committed to providing our customers with the highest quality products, backed by our expertise in the industry.

With us, you can expect a wide range of worm gearboxes to choose from, including those suited for industrial and heavy-duty applications. Our products are sourced from leading manufacturers, ensuring that they meet the highest standards of quality and reliability.

But our commitment to our customers doesn’t stop here. We also offer exceptional customer service, with a team of experts on hand to help you choose the right product for your specific needs. And if you have any questions or concerns about your purchase, we are always available to provide support and guidance. Contact us today to learn more about our worm gearboxes, other products and services and how we can help you find the perfect solution for your needs.