A worm gear is a mechanical device that has a shaft that bears spiral threads. These spiral threads fit into the grooves of traditional gear and drive its toothed wheel. A worm gearbox offers several benefits. Reduction gearboxes can give you high torque with low-speed ratios. With a worm box, you can reach higher gear ratios as compared to helical gearboxes.

Because of the high productivity and durability of worm gearboxes, they have applications across sectors including, textiles, cement, mining, automobiles and many more:

So if you are mulling purchasing a reduction gearbox, here are a few things you must consider before buying one:

What is Worm Gearbox and Things to Consider When Buying a Worm GearBox

1. Types of Worm Gearboxes

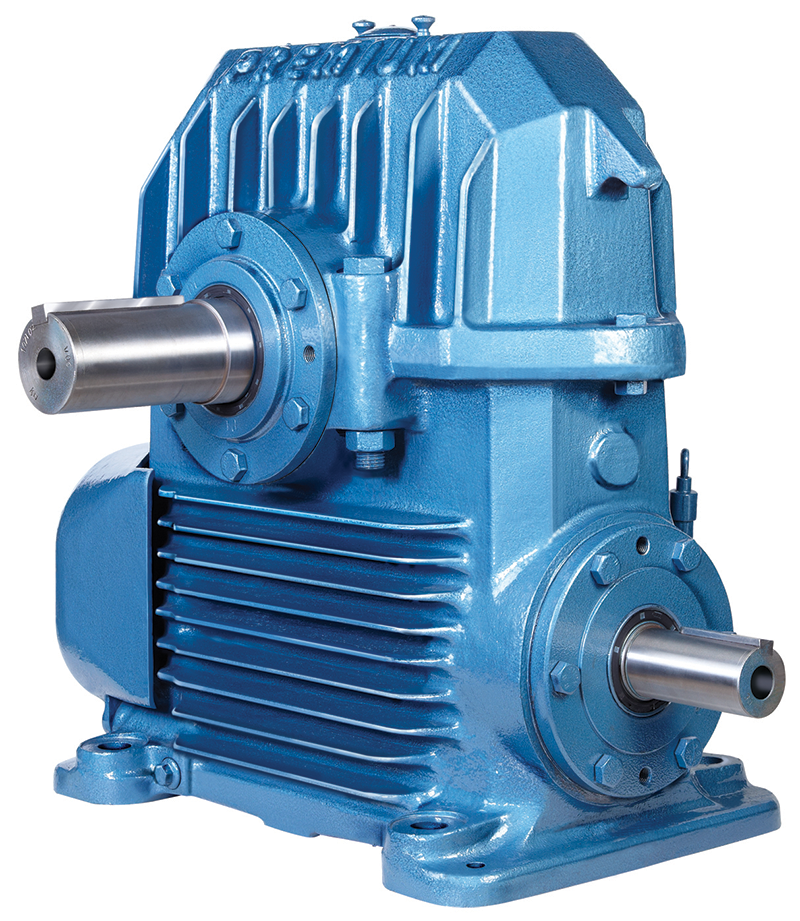

Identify the reduction gearbox that fits your requirement after understanding the different types of worm gearboxes. You can find three types of gearboxes – Non-enveloping, single envelope and double envelope. The non-enveloping type does not have concave features. In this type, a contact point is a straight plane that places stress on the gearbox.

In a single envelope, you will find the gear has a concave tooth width. As a result, the worm drives deeper into the gear and increases efficiency. A double envelope, on the other hand, contains a wide gear with a concave tooth width and a worm drive with a concave design. You can check out the Premium Transmission gearboxes by Santram Engineers to get a good understanding of the different types of Worm Gearboxes.

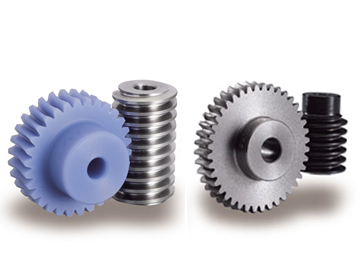

2. Tooth Spacing

Tooth spacing is an important aspect that you must consider before selecting the reduction gearbox. Tooth spacing has several parameters such as Diametral Pitch, Circular Pitch, Module, Pressure Angle and Lead Angle. Remember that worm drives and worm wheels must have the same pitch and pressure angle to mesh, but may not mesh if the envelope concavity does not match.

3. Applications

Make sure you consider the application of the worm reduction gearbox before you pick out a gearbox. Understand its power, velocity and torque consistency to ensure that the gearbox meets the mechanical requirements. Also, understand the inertia of the gear. Heavier gears could be difficult to stop or reverse.

Understand the precision mechanism of the gearbox. This means you will have to take a closer look at the gear pitch, pressure angle, tooth layout and shaft diameter.

Other factors you need to look at and understand include handedness, mounting requirements, noise limitation, corrosion resistance, temperature exposure, vibration and shock resistance, etc.

4. Material

Due to the wear and tear that a reduction gearbox has to undergo, the material used for making gearboxes is usually heavy. From cast iron to carbon steel, gearboxes are available in a wide variety of materials. You can find gearboxes in alloy steel, cast steel, carbon steel, cast iron, aluminium, brass, copper, plastic and even wood.

All materials have very specific functions. So to pick out the right material, understand the benefit of each material and pick the one that suits your business requirement best.

Need professional advice? You can consult the experts at Santram Engineering – the leading supplier of Power Transmission Products.

Let Us Help You Pick Out the Right Reduction Gearbox

Santram Engineers has decades of experience in Power Transmission products. For queries regarding reduction gearboxes, you can call us at +91-96247 39393 or write to us at sales@santramengineers.com. We would be happy to help!