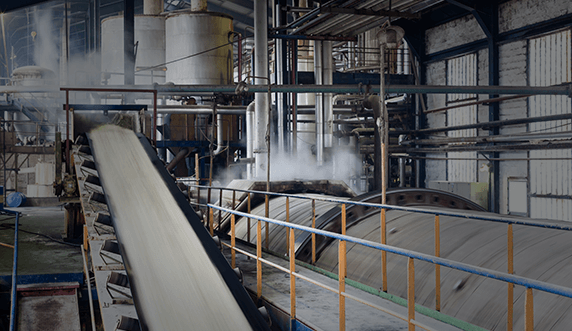

Sugar mills in India play an essential role in the country’s economy. They employ thousands of people and generate significant revenue for the nation. However, to keep the mills running smoothly and efficiently, maintenance is crucial. One key component that requires regular maintenance is the planetary mill gearbox.

This article discusses the importance of maintenance for planetary gearboxes in sugar mills. We highlight the benefits of regular maintenance and the consequences of neglecting it. In addition, we provide tips for effective maintenance and the importance of partnering with reliable planetary gearbox manufacturers.

Why You Should Maintain Planetary Gearboxes

Planetary gearboxes are an integral part of sugar mills. They are responsible for transmitting power from the motor to the cane-crushing rollers. Therefore, if a gearbox fails, the entire mill operation comes to a halt, leading to significant losses in production and revenue.

Regular maintenance of planetary gearboxes is essential to ensure their optimal performance. Over time, wear and tear can occur due to friction, heat, and other factors, causing the gearbox to fail. This failure can be catastrophic and result in the need for costly repairs or even replacement.

Benefits of Regular Maintenance

Regular maintenance ensures planetary mill gearboxes operate at peak performance and last as long as possible. The benefits of regular maintenance are numerous, including:

1. Increased Lifespan

A gearbox that is properly maintained will last longer than one that is neglected. Regular maintenance, including proper lubrication and cleaning, can prevent premature wear and tear of gearbox components. This can significantly extend the lifespan of the gearbox, reducing the need for expensive replacements.

2. Improved Performance

Regular maintenance can help ensure that planetary gearboxes operate at optimal performance levels. Properly lubricated gearboxes run more smoothly and quietly, providing the necessary power to the cane-crushing rollers. This, in turn, leads to more efficient and productive mill operations.

3. Reduced Downtime

Downtime can be costly for sugar mills, leading to lost production and revenue. Regular maintenance can help prevent unexpected failures, reducing the likelihood of downtime and associated costs. By addressing potential issues early on, technicians can avoid more severe problems down the line that could cause unplanned downtime.

4. Lower Repair Costs

Neglecting maintenance can lead to significant damage to the gearbox, resulting in the need for costly repairs. Regular maintenance can identify potential issues before they become severe, reducing the need for extensive repairs. Addressing small problems early on can prevent larger and more expensive issues from arising in the future.

5. Improved Safety

Proper maintenance can help ensure that planetary gearboxes operate safely. A well-maintained gearbox is less likely to experience sudden failures or breakdowns, reducing the risk of accidents or injuries in the sugar mill. Regular inspections and maintenance can also identify any safety hazards or potential risks, allowing for timely corrections before accidents occur.

6. Compliance with Regulations

Sugar mills in India are subject to various regulations and safety standards. Regular maintenance can help ensure planetary gearboxes comply with these regulations, reducing the risk of penalties or fines. A well-maintained gearbox is also more likely to pass inspections and audits, ensuring compliance with all necessary standards.

Consequences of Neglecting Maintenance

Neglecting the maintenance of planetary gearboxes can have severe consequences for sugar mills, including:

1. Downtime

When a gearbox fails unexpectedly, it can lead to downtime, which can be costly for sugar mills. Downtime leads to lost production and revenue and can damage the mill’s reputation with customers. The longer the downtime, the greater the impact on the mill’s profitability.

2. Increased Repair Costs

Neglecting maintenance can cause significant damage to the gearbox, resulting in the need for costly repairs or even replacement. Gearboxes are complex machines, and repairing them can be time-consuming and expensive. Neglecting maintenance can accumulate small problems that eventually escalate into larger, more expensive issues.

3. Safety Hazards

A poorly maintained gearbox can be a safety hazard for workers and equipment. Gearboxes that are not properly lubricated can overheat, causing metal components to warp or crack. This can lead to catastrophic failure and even explosion. In addition, loose or worn components can cause parts to come loose and cause damage or injury.

4. Reduced Efficiency

A poorly performing gearbox can result in reduced efficiency and productivity. A planetary gearbox that is not adequately lubricated or cleaned can lead to increased friction and wear on the components, which can reduce power transmission efficiency. Reduced power transmission efficiency can result in the mill being unable to achieve its desired production targets. This can lead to lower revenue and profits for the mill.

5. Damage to Other Components

Neglecting the maintenance of the gearbox can damage other components of the mill, including the rollers and motors. For example, a gearbox that is not properly lubricated can cause excessive friction on the rollers, leading to wear and tear on the rollers and requiring early replacement.

Tips for Effective Maintenance

Effective maintenance of planetary gearboxes requires a systematic approach. Here are some tips to follow:

- Regular lubrication: Proper lubrication is crucial for a gearbox’s optimal performance and longevity. Regularly lubricate the gearbox according to the manufacturer’s guidelines.

- Cleaning: Regularly clean the gearbox to remove any debris or contaminants that can cause damage.

- Inspection: Regularly inspect the gearbox for any signs of wear and tear. Identify potential issues early to prevent costly repairs or replacement.

- Partner with reliable manufacturers: Partnering with reliable manufacturers of planetary gearboxes is crucial for effective maintenance. They can provide expert guidance on maintenance procedures and ensure the availability of spare parts.

Importance of Partnering with Reliable Planetary Gearbox Manufacturers

Partnering with reliable planetary gearbox manufacturers is crucial for the effective maintenance of sugar mill gearboxes. Here are some of the key benefits:

- Expert guidance: Reliable manufacturers can provide expert guidance on maintenance procedures, ensuring the maintenance is carried out correctly and efficiently.

- Quality spare parts: They can supply quality spare parts designed to work with their gearboxes. This ensures that the gearbox performs optimally and reduces the likelihood of failure.

- Warranty support: They provide warranty support for their gearboxes, which can be critical in a failure. This provides peace of mind for the sugar mill owners, knowing they have the manufacturer’s support in case of any issues.

- Technical support: They can provide technical support, including troubleshooting and repair services. This ensures issues are resolved promptly and effectively, reducing downtime and associated costs.

Frequently Asked Questions

-

How often should planetary mill gearbox maintenance be performed?

It is recommended that the maintenance should be performed at least once a year. However, more frequent maintenance may be necessary depending on the sugar mill’s specific operating conditions and requirements. Consult with the planetary gearbox manufacturer for specific recommendations on maintenance frequency.

-

Can sugar mills perform gearbox maintenance themselves?

While sugar mills can perform basic maintenance tasks such as lubrication and visual inspections, it is recommended to consult qualified technicians or gearbox manufacturers to perform more in-depth maintenance. This ensures that maintenance is performed correctly and potential issues are promptly identified and addressed.

-

How can sugar mills identify potential gearbox issues?

There are several ways sugar mills can identify potential gearbox issues. One of the most effective ways is through regular visual inspections, looking for signs of wear and tear or damage. In addition, monitoring the gearbox’s temperature and vibration levels can provide early warning signs of potential issues. Sugar mills are also recommended to work with reputable gearbox manufacturers that can provide diagnostic services and identify potential issues through regular maintenance.

-

What are the most common causes of gearbox failure?

The most common causes of planetary gearbox failure include improper lubrication, overheating, vibration, and contamination. Gearboxes that are not correctly lubricated can cause excessive friction and wear on the components, leading to premature failure. Overheating can cause metal components to warp or crack, leading to catastrophic failure. Vibration can cause parts to lose or wear out quickly, leading to premature failure. Contamination, such as dirt or debris, can cause damage to the components and reduce efficiency.

-

Can regular maintenance of planetary mill gearboxes save money for sugar mills?

Yes, regular maintenance of gearboxes can save money for sugar mills in the long run. By identifying and addressing potential issues early on, mills can avoid costly repairs and replacements. In addition, a well-maintained gearbox will perform more efficiently, leading to greater productivity and profitability. Regular maintenance can also help prevent unexpected downtime, which can be costly for sugar mills.

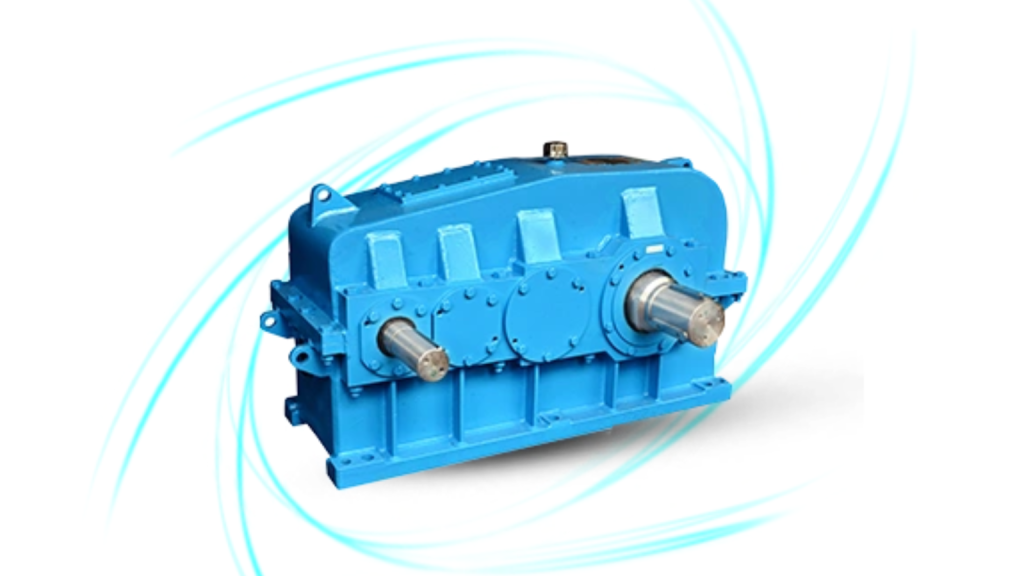

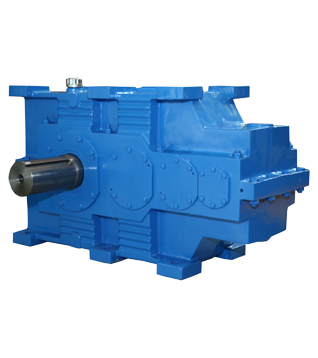

Where to Find the Best Quality Planetary Mill Gearboxes in India

When looking for the best quality planetary gearboxes in India, it is essential to work with reputable and experienced manufacturers and suppliers with a proven track record of producing reliable and efficient gearboxes. As one of the most trusted suppliers and dealers of gearboxes in India, Santram Engineers offers a wide range of planetary gearboxes built to last and provide exceptional performance.

Whether in the steel, mining, or cement industry, we have the expertise to help you find the perfect gearbox for your application. With a commitment to quality and customer satisfaction, you can trust Santram Engineers to provide you with the highest quality products at competitive prices.

Contact us today to find out more about our extensive range of planetary mill gearboxes and take your business to the next level.