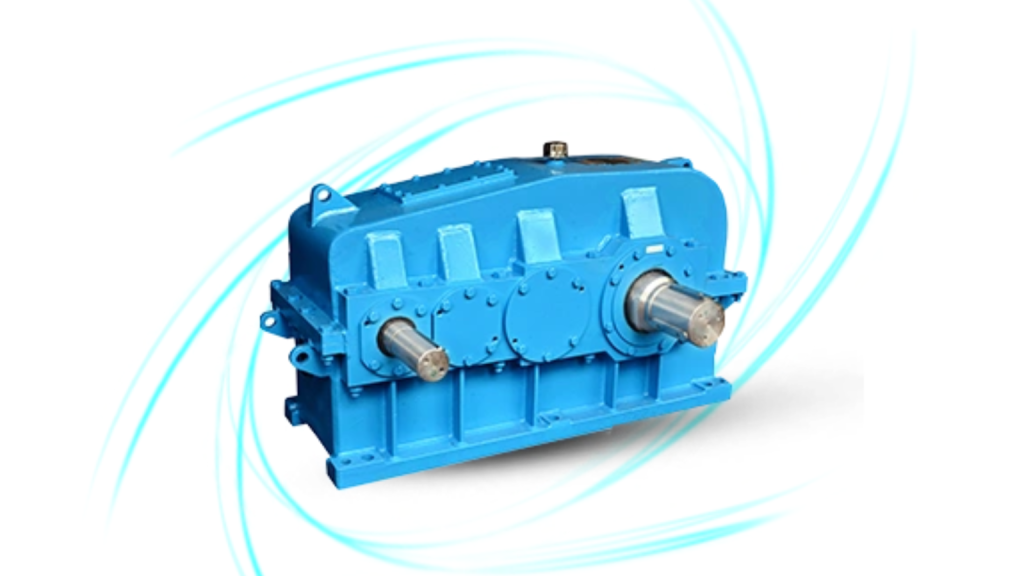

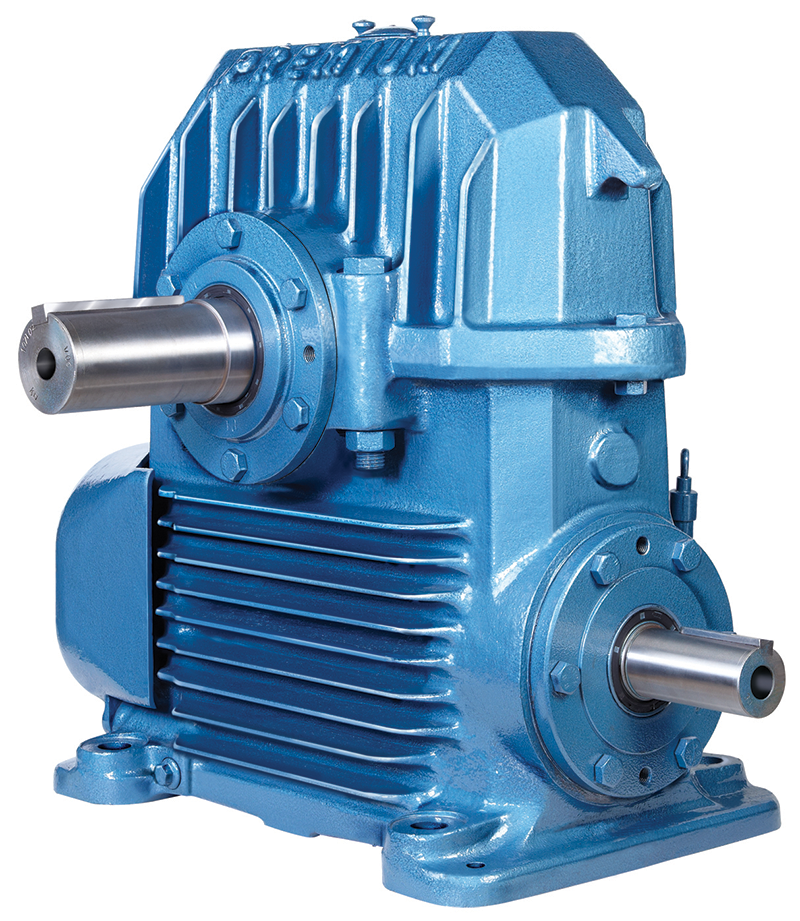

In industrial machinery and mechanical systems, worm gearboxes play a crucial role, offering efficient power transmission and precise control across various applications. As businesses seek reliable and durable solutions for their operational needs, these gearboxes emerge as essential components due to their unique characteristics and versatile functionalities.

This article explores five important applications of worm gearboxes, shedding light on their diverse uses and benefits across different sectors.

Application 1: Dam Gate Application

One of the significant applications of worm gearboxes is in dam gate operations, where the need for robust and dependable gear systems is paramount. Dam gates are crucial components of water management infrastructure, controlling the flow and level of water in reservoirs, rivers, and canals. The operational efficiency and safety of these gates depend heavily on the performance of the gearboxes driving them.

Specific Benefits & Key Points

- High Torque Transmission: Worm gearboxes excel in applications requiring high torque transmission, making them ideal for operating heavy dam gates. The unique worm and wheel design enables them to handle substantial loads efficiently.

- Space-Efficient Design: The gearboxes are compact and can be installed in confined spaces, which is advantageous in dam gate setups where space is limited.

- Self-Locking Feature: A notable advantage is their inherent self-locking property. This feature prevents the back-driving of the gate, ensuring stable positioning and enhanced safety.

- Smooth and Quiet Operation: With reduced noise levels and smooth operation, worm gearboxes contribute to a quieter and more controlled environment around dam structures.

- High Durability and Low Maintenance: They are known for their durability and minimal maintenance requirements. This makes them a cost-effective choice for long-term applications like dam gate operations.

Application 2: Industrial Elevators

In vertical transportation within industrial settings, worm gearboxes play a vital role in powering and controlling industrial elevators. These elevators are essential for efficiently moving personnel, equipment, and materials between different levels of large facilities such as manufacturing plants, warehouses, and distribution centers. The reliability and performance of the elevator gearbox are critical for ensuring safe and smooth vertical movement within these environments.

Specific Benefits & Key Points

- Heavy Load Capacity: Industrial elevators often need to lift heavy loads reliably. Worm gearboxes are well-suited for this task due to their ability to transmit high torque efficiently, enabling the safe transportation of heavy equipment and materials.

- Safety and Stability: They contribute to the safety and stability of industrial elevators. Their self-locking feature prevents the elevator from descending unexpectedly, providing a secure and controlled environment for passengers and cargo.

- Smooth Operation: They function with least vibration and noise, ensuring a smooth and comfortable ride for elevator users. This characteristic is particularly important in industrial settings where noise and disturbances can impact productivity and safety.

- Space Efficiency: The compact design of the gearboxes allows for efficient use of space within elevator shafts and machine rooms. This is advantageous in crowded industrial facilities where space optimization is essential.

- Reliability and Durability: They are known for their durability and longevity, requiring minimal maintenance over their operational lifespan. This reliability is crucial for minimizing downtime and ensuring continuous elevator operation in industrial environments.

- Customisable Solutions: Leading worm gearbox manufacturers offer customisable solutions tailored to the specific requirements of industrial elevator applications. This includes considerations such as load capacity, speed, and environmental factors, ensuring optimal performance and safety.

Application 3: Construction Machinery Industry

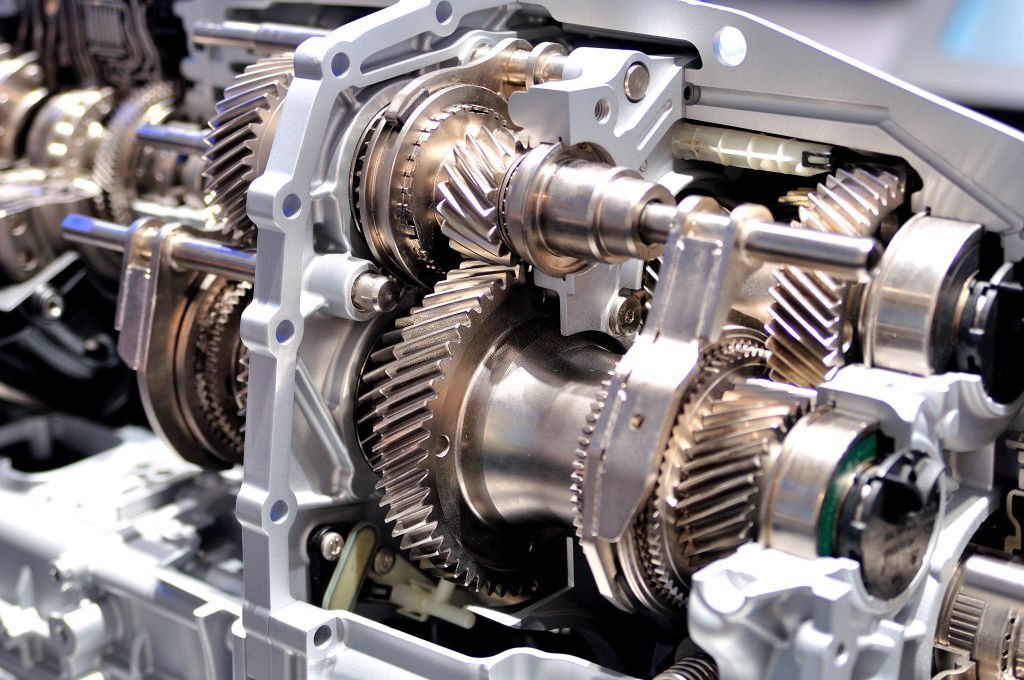

Worm gearboxes are essential in the construction machinery industry, powering a wide range of equipment used in building, infrastructure development, and earthmoving tasks. From concrete mixers and cranes to excavators and conveyor systems, these gearboxes contribute to the efficient operation and performance of construction machinery under demanding conditions.

Specific Benefits & Key Points

- High Torque Transmission: Construction machinery often requires high torque to handle heavy loads and challenging terrain. The gearboxes excel in transmitting high torque efficiently, enabling the smooth and powerful operation of equipment like excavators and cranes.

- Compact Design: The compact size makes them suitable for integration into various construction machinery without occupying excessive space. This space-saving feature is crucial in optimising the design and functionality of construction equipment.

- Stable Positioning and Control: They offer excellent stability and precise control over machinery movements, enhancing safety and efficiency on construction sites. Their self-locking capability ensures that equipment remains securely positioned, reducing the risk of accidents.

- Durability and Reliability: Construction machinery operates in harsh environments characterised by dust, debris, and heavy vibrations. Worm gearboxes are engineered to withstand these conditions, providing reliable performance and durability over extended periods.

- Customisable Solutions: Leading worm gearbox manufacturers offer customised solutions tailored to the specific requirements of construction machinery applications. This includes considerations such as gear ratio, speed, and load capacity to optimise performance and efficiency.

- Low Maintenance Requirements: The gearboxes are designed for minimal maintenance, reducing downtime and operational costs for construction businesses. This reliability is crucial for maximising productivity and profitability in the construction industry.

- Cost-Effective Solutions: They offer cost-effective solutions for construction machinery applications compared to alternative gearbox technologies. Their efficiency in torque transmission and durability contribute to overall cost savings for construction businesses.

Application 4: Packaging Industry

Worm gearboxes are crucial in the packaging industry, powering a variety of machines used for filling, sealing, labelling, and packaging goods. In this fast-paced sector where efficiency and precision are paramount, these gearboxes offer reliable power transmission and control. This ensures the smooth and accurate operation of packaging equipment.

Specific Benefits & Key Points

- Precise Speed Control: Worm gearboxes provide precise speed control essential for packaging machines to operate at optimal speeds for different tasks such as filling, sealing, and labelling. This precision enhances productivity and consistency in packaging operations.

- Compact Design: The compact size allows them to be integrated seamlessly into packaging machinery, optimising space utilisation on production floors. This is particularly advantageous in modern packaging facilities with limited space.

- High Torque Transmission: Packaging machines often require high torque to handle tasks such as sealing and cutting packaging materials. Worm gearboxes excel in transmitting high torque efficiently, enabling the smooth and powerful performance of packaging equipment.

- Durability and Reliability: They are designed to withstand the rigorous demands of continuous operation in the packaging industry. Their durability and reliability minimise downtime and maintenance, ensuring uninterrupted production cycles.

- Low Noise and Vibration: They operate with minimal noise and vibration, contributing to a quieter and more pleasant working environment in packaging facilities. This is crucial for maintaining a comfortable workplace and enhancing worker efficiency.

- Customisable Solutions: Leading worm gearbox manufacturers offer solutions tailored to the specific requirements of packaging applications. This includes considerations such as gear ratio, motor compatibility, and environmental factors to optimise performance and efficiency.

- Ease of Maintenance: The gearboxes are engineered for low maintenance, reducing the need for frequent servicing and repairs. This results in lower operational costs and increased uptime for packaging businesses.

Frequently Asked Questions

1. What are the main advantages of using worm gearboxes?

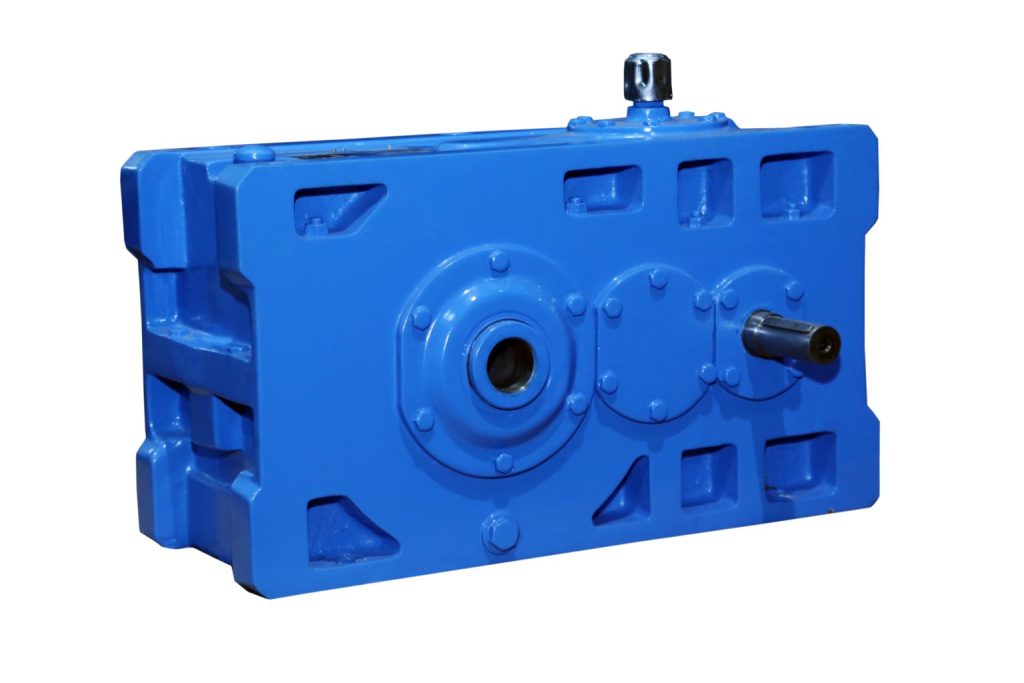

Worm gearboxes offer several advantages, including high torque transmission, compact design for space efficiency, self-locking capability, smooth and quiet operation, and low maintenance requirements. These features make them ideal for various industrial applications.

2. In which industries are worm gearboxes commonly used?

Worm gearboxes find widespread use in industries such as manufacturing, construction, packaging, agriculture, transportation, and mining. They are employed in equipment like conveyor systems, cranes, elevators, mixers, and packaging machines.

3. How do I choose the right worm gearbox for my application?

When selecting a worm gearbox, consider factors such as required torque and speed, operating environment (e.g., temperature, humidity), space constraints, and specific application requirements (e.g., continuous operation, intermittent use). It helps to consult an experienced industrial gearbox supplier for recommendations.

4. What maintenance is required for worm gearboxes?

These gearboxes are generally low-maintenance, requiring periodic checks for lubrication and wear. Regular inspection of gears, bearings, and seals is recommended to ensure optimal performance and longevity.

5. Are worm gearboxes suitable for heavy-duty applications?

Yes, they are well-suited for heavy-duty applications due to their ability to transmit high torque efficiently. They are commonly used in machinery that handles heavy loads such as cranes, hoists, and material-handling equipment.

6. Can worm gearboxes be customised for specific needs?

Leading worm gearbox manufacturers offer customisable solutions to individual requirements. This includes options for gear ratio, mounting configurations, shaft orientation, and motor compatibility to meet diverse application needs effectively.

Order Your Premium Quality Worm Gearboxes at Santram Engineers

Ready to upgrade your industrial machinery with premium-quality worm gearboxes? Take your operations to the next level with innovative gearbox solutions at Santram Engineers. We are one of the leading industrial gearbox suppliers in India offering a wide range of gear solutions.

Order now to experience the benefits of reliable power transmission, efficient torque delivery, and space-saving designs that optimize your equipment performance. Our gearboxes are engineered for durability, ensuring minimal maintenance and maximum uptime for your business.

Whether you’re in manufacturing, construction, logistics, or any industry that relies on robust gear systems, we have you covered. Our expertly crafted worm gearboxes from Premium Transmission are tailored to meet your specific needs. Enhance productivity, improve safety, and reduce operational costs with our premium gearbox solutions.

Contact us at +91-96247 39393 or write to us at sales@santramengineers.com to discuss your requirements and place your order for premium-quality worm gearboxes. Let us be your trusted partner in driving efficiency and success in your operations.