In the dynamic world of industrial operations, maintaining efficiency and productivity is crucial. This importance holds good even in the sugar production industry, where precision machinery is vital. Central to this machinery are industrial gearboxes that ensure seamless operations within sugar mills.

As one of the leading industrial gearbox suppliers in India, we have compiled this guide to help you explore how preventive maintenance can enhance gearbox performance and significantly reduce operational costs.

Significance of Gearboxes in Sugar Production

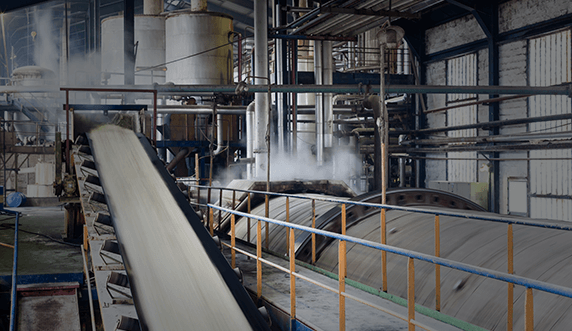

Industrial gearboxes are the backbone of sugar mills, transmitting power from motors to various mechanical components. They ensure the necessary speed reductions and torque increases needed to drive cane crushers, conveyors, and other essential machinery in the sugar production process.

Gearbox Function in Sugar Mills

In sugar mills, gearboxes are used across various applications, each demanding specific torque and speed characteristics. Whether driving cane-crushing rollers or powering centrifugal machines, the gear systems ensure efficient energy transfer and operational reliability under varying load conditions.

The process of sugar production involves several stages, each requiring precise control over speed and torque. For instance, the initial crushing of sugarcane necessitates high torque to break down the tough fibers, while subsequent processes like juice extraction and sugar crystal formation require carefully controlled speeds to ensure optimal quality and yield. Gearboxes, therefore, play a crucial role in maintaining these precise conditions, directly impacting the overall efficiency and productivity of the mill.

Common Types of Industrial Gearboxes Used

Sugar mills typically use several types of gearboxes tailored to specific tasks. The common ones include:

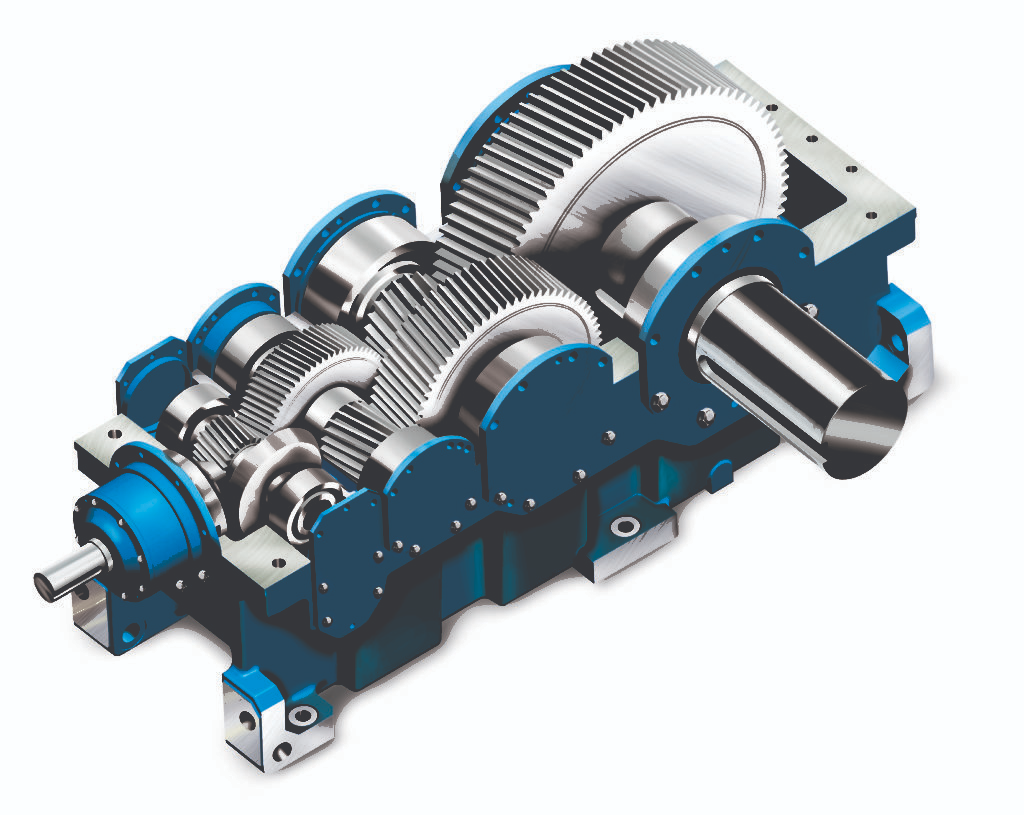

- Helical Gearboxes: Known for smooth operation and high efficiency, they are used in cane crushing. These gearboxes offer the advantage of low noise and high torque transmission, making them ideal for applications that require precise speed control.

- Bevel Helical Gearboxes: These are ideal for driving conveyor systems and providing seamless torque transmission. These gearboxes are preferred in applications where space constraints and high torque requirements intersect, offering flexibility and efficiency in design.

Each type of gearbox is designed to handle specific operational demands. The choice of gearbox depends on factors such as the type of machinery it will drive, the required speed and torque, and the environmental conditions in which it will operate. Industrial gearbox suppliers such as Santram Engineers provide tailored solutions to meet these specific needs, ensuring optimal performance and longevity.

Impact of Gearbox Failure on Production

Gearbox failures can disrupt sugar mill operations, leading to costly downtime and production losses. A malfunctioning gearbox can halt cane processing and jeopardise delivery timelines. Beyond immediate financial losses, such breakdowns can harm a mill’s reputation for reliability and efficiency.

When a gear system fails, the ripple effects are felt throughout the entire production process. For instance, if a gearbox driving a critical component such as the cane crusher fails, the entire production line can come to a standstill. This not only results in lost production time but also increases the pressure on other components, potentially leading to further breakdowns and compounding the problem.

Moreover, the financial implications of gearbox failures extend beyond the immediate cost of repairs and replacement parts. Unplanned downtime can result in missed production targets, delayed shipments, and contractual penalties. Over time, repeated failures can erode customer trust and damage the mill’s reputation, making it harder to secure future business. Collaborating with reputed industrial gearbox suppliers is the first step that can help you overcome this challenge.

The Benefits of Preventive Maintenance (PM)

Preventive maintenance is more than just routine care. It is a strategic approach to equipment management. By anticipating potential problems and addressing them before they escalate, PM helps maintain optimal performance and extends the lifespan of critical components. This proactive stance reduces the likelihood of unexpected failures and also contributes to a more stable and predictable production environment.

Cost Savings Achieved

The financial benefits of PM are multifaceted. First, by reducing the frequency and severity of breakdowns, PM minimises the need for expensive emergency repairs. This not only cuts repair costs but also reduces the downtime associated with such repairs, allowing production to resume more quickly.

Second, PM helps extend the lifespan of critical components. By ensuring that gearboxes and other machinery operate within their optimal parameters, PM reduces wear and tear, delaying the need for costly replacements. This, in turn, lowers capital expenditure and improves the return on investment for industrial equipment.

Finally, PM contributes to improved operational efficiency. By maintaining equipment in peak condition, it helps ensure production processes run smoothly and consistently, maximising output. This boosts productivity and enhances overall profitability. You can get more practical information on this from leading industrial gearbox suppliers.

Key Components of a Premium Maintenance Program

Implementing a comprehensive preventive maintenance program is essential for maximising gearbox efficiency and longevity. Here are the key components of the approach:

Regular Inspections and Monitoring

Regular inspections and monitoring are central to effective PM. Scheduled inspections allow maintenance personnel to assess the condition of critical components such as gears, bearings, seals, and lubricants.

Inspections should be both comprehensive and systematic. Visual inspections can identify obvious signs of wear or damage, such as cracks, leaks, or corrosion. However, more sophisticated techniques, such as vibration analysis and thermography, provide deeper insights into the health of the equipment. Vibration analysis can detect issues such as misalignment, imbalance, or bearing defects, while thermography can identify hotspots indicative of overheating or excessive friction.

By combining these techniques, maintenance teams can develop a holistic understanding of the condition of their gearboxes and other critical components. This enables them to take targeted actions to address potential issues, improving the overall reliability and performance of the equipment.

Lubrication Best Practices

Lubrication practices should be guided by manufacturer or reputed industrial gearbox supplier’s recommendations and tailored to the specific needs of each gearbox. Factors such as operating temperature, load conditions, and environmental factors can all influence the choice of lubricant and the frequency of lubrication.

Regular oil sampling and analysis are critical components of a lubrication program. By analysing the condition of the lubricant, maintenance teams can detect signs of contamination, degradation, or wear. This information enables them to take corrective actions, such as changing the oil, cleaning the system, or addressing underlying issues, before they lead to more serious problems.

Proper lubrication practices reduce friction and wear and help dissipate heat, prevent corrosion, and extend the life of gears, bearings, and seals. This, in turn, improves the overall performance and reliability of the gearboxes and other machinery.

Replacement Schedules for Gearbox Components

Establishing a proactive replacement schedule for gearbox components minimises the risk of unexpected failures and maximises equipment uptime. Components like gears, bearings, seals, and gaskets have finite lifespans influenced by operating conditions and maintenance practices. A data-driven approach to component replacement, leveraging predictive maintenance techniques, ensures timely replacements based on wear patterns and historical performance data.

Predictive maintenance techniques use historical performance data and advanced analytics to predict when components are likely to fail. By analysing wear patterns, operating conditions, and other factors, maintenance teams can develop accurate replacement schedules that minimise the risk of unexpected failures.

Proactive component replacement helps ensure gearboxes and other machinery operate within their optimal parameters, reducing the likelihood of breakdowns and improving overall reliability.

Tools and Technologies for Effective Gearbox Maintenance

Reputed industrial gearbox suppliers recommend integrating advanced tools and technologies to enhance gearbox maintenance practices, to improve operational excellence and cost savings.

Use of Condition Monitoring Systems

Condition monitoring systems provide valuable insights into the health of gearboxes, enabling maintenance teams to identify and address issues before they become critical. These systems utilise a variety of sensors and data collection methods to monitor key parameters in real-time.

- Vibration Monitoring: By measuring the vibrations of a gearbox, maintenance teams can detect anomalies such as misalignment, imbalance, or bearing defects. Abnormal vibration patterns are often early indicators of mechanical problems.

- Temperature Monitoring: Elevated temperatures can indicate excessive friction, inadequate lubrication, or other operational issues. Continuous temperature monitoring helps ensure gearboxes operate within their optimal temperature range.

- Lubricant Condition Monitoring: Analysing the condition of lubricants, including viscosity, contamination levels, and chemical composition, provides insights into the wear and health of the gearbox. Early detection of lubricant degradation can prevent significant damage.

These condition monitoring systems help in early detection of issues and enable predictive maintenance strategies, which are more cost-effective and less disruptive than reactive maintenance.

Importance of Data Analytics in Predictive Maintenance

Data analytics is the cornerstone of effective predictive maintenance strategies for industrial gearboxes. By leveraging historical data, machine learning algorithms, and predictive models, manufacturers can forecast equipment performance trends and anticipate maintenance needs with precision.

- Historical Data Analysis: Analysing past performance data helps identify patterns and trends that indicate when a gearbox is likely to experience issues. This information is crucial for planning maintenance activities and avoiding unexpected breakdowns.

- Machine Learning Algorithms: These algorithms can process large volumes of data to identify subtle correlations and predictive indicators that might be missed by traditional analysis methods. They continuously improve their accuracy over time as more data is collected.

- Predictive Models: Using predictive models, maintenance teams can simulate various scenarios and predict the impact of different maintenance strategies. This allows for optimised scheduling of maintenance activities to minimise downtime and costs.

By integrating sophisticated data analytics capabilities into maintenance programs, sugar mills can achieve higher levels of reliability and operational efficiency. It significantly helps to consult industrial gearbox suppliers to integrate latest technologies.

Choosing the Right Industrial Gearbox Suppliers

Selecting the right industrial gearbox supplier is a strategic decision that significantly impacts the performance and reliability of sugar mill operations. Several critical factors should be considered when evaluating potential suppliers:

Factors to Consider

- Product Quality and Reliability: Opt for suppliers known for manufacturing high-quality gearboxes that adhere to industry standards and regulatory requirements. Reliable gearboxes minimise maintenance interventions and maximise productivity.

- Customisation and Application Expertise: Choose suppliers with a proven track record in designing and customising gearboxes to suit specific applications within the sugar industry. Expertise in understanding operational requirements and offering tailored solutions ensures optimal performance and longevity.

- Service and Support: Evaluate the industrial gearbox supplier’s commitment to customer support, including availability of technical assistance, spare parts, and after-sales service. A responsive support network is essential for addressing maintenance issues promptly and minimising downtime.

- Innovation and Technological Capabilities: Partner with suppliers at the forefront of innovation, integrating advanced technologies such as IoT-enabled monitoring systems and predictive maintenance solutions. These innovations drive continuous improvement in gearbox reliability and performance.

Importance of Reliability and Service Support

Reliability and comprehensive service support are non-negotiable attributes when selecting an industrial gearbox supplier. Sugar mills operate under demanding conditions that require robust, dependable equipment capable of withstanding rigorous use. A reliable supplier not only delivers quality gearboxes but also stands behind their products with extensive service capabilities, ensuring minimal disruptions and maximum uptime for mill operations.

Frequently Asked Questions (FAQs)

1. How often should industrial gearboxes in sugar mills undergo inspections?

The frequency of inspections varies based on operating conditions and manufacturer recommendations. Typically, gearboxes should undergo regular visual inspections and comprehensive checks during scheduled maintenance intervals.

2. Can condition monitoring systems prevent gearbox failures proactively?

Yes, condition monitoring systems continuously monitor gearbox parameters such as vibration, temperature, and lubricant conditions. By detecting anomalies early, they enable proactive maintenance actions to prevent costly failures.

3. What are the signs that indicate a gearbox might need maintenance?

Common signs include unusual noises, increased vibration, overheating, and visible oil leaks. Additionally, a noticeable drop in performance or efficiency and irregular wear patterns on gears and bearings are strong indicators that maintenance is required.

4. How does choosing a reputable gearbox supplier impact long-term operational costs?

Partnering with a reputable supplier ensures high-quality, durable gearboxes that require less frequent repairs and replacements. This reliability reduces downtime and maintenance costs, ultimately lowering long-term operational expenses and enhancing overall efficiency.

Contact a Leading Industrial Gearbox Supplier

Santram Engineers is the largest industrial gearbox supplier and distributor for Premium Transmission Private Limited, a leading manufacturer of high quality gearboxes. We are renowned for innovative solutions and superior customer service. Our expertise spans customised gearbox designs, advanced predictive maintenance technologies, and comprehensive service support to ensure minimal downtime and maximum productivity.

Whether you’re seeking to optimise gearbox performance, enhance reliability through preventive maintenance programs, or explore cutting-edge solutions in gearbox technology, we’re here to partner with you every step of the way. Reach out to us at +91 96247 39393 or email us at sales@santramengineers.com and discover how we can tailor our solutions to meet your specific needs, ensuring your sugar mill operates at peak performance consistently.