An industrial gearbox plays a vital role in several industries by transmitting and transferring power and torque to the machine from the original motor. The gearbox manages the output shaft’s overall direction and general speed, allowing it to adjust and change according to the application’s requirements. There are several different kinds of Industrial Gearboxes all developed for a particular usage.

Today, We Will Discuss The Most Common Types of Industrial Gearboxes and Their Uses

1. Helical Gearboxes

According to Bombay gearbox dealers, helical gearboxes are the most popular and standard type of gearboxes used across industries. They have a vast range of applications, from material handling equipment and conveyors to heavy-duty machinery. Helical gears are silent and smooth compared to other gears, making them perfect for operations where reducing noise is essential.

They are much more efficient and supply great power transmission levels compared to different gear types. Helical Gears and their teeth are cut and placed at a precise angle, allowing for more incremental contact during operation.

This method and design choice decreases the noise and vibration levels generated by the gearboxes. Helical gearboxes can also be found in diverse dimensions and ratios, causing them versatile and adaptable for a wide range of usage and applications.

2. Bevel Gearboxes

Bevel gearboxes are employed in applications where the shafts, both input and output, are at a specific angle.

They are typically operated in the automotive, mining, and marine industries and more, along with Power Transmission Products. Bevel gearboxes are developed to endure heightened torque and are available in right-angle and straight designs, according to Bombay gearbox dealers.

Bevel gears maintain teeth cut at a specific angle, permitting them to transmit power amidst two non-parallel shafts. The teeth of the bevel gear are commonly cut at a 90-degree angle, letting the gearboxes transmit power better amongst two perpendicular shafts.

3. Worm Gearboxes

Worm Gearboxes are utilized in various applications requiring higher gear reduction. They are typically employed in packaging machinery, conveyor systems, and material handling gear.

These gearboxes are also compact in design, efficient and deliver an increased level of precision. They also self-lock, which causes them to be excellent for uses where the load must be held in position.

Worm gears have an innovative design allowing a high gear reduction balance in a little space. The teeth of the worm gear are placed at an angle, which lets it mesh along with the teeth of the worm wheel.

The worm gear spins the worm wheel, which ends up in a high gear reduction ratio. Worm gearboxes are immaculate for applications that demand a high tier of accuracy and accurate positioning, according to experienced Bombay gearbox dealers.

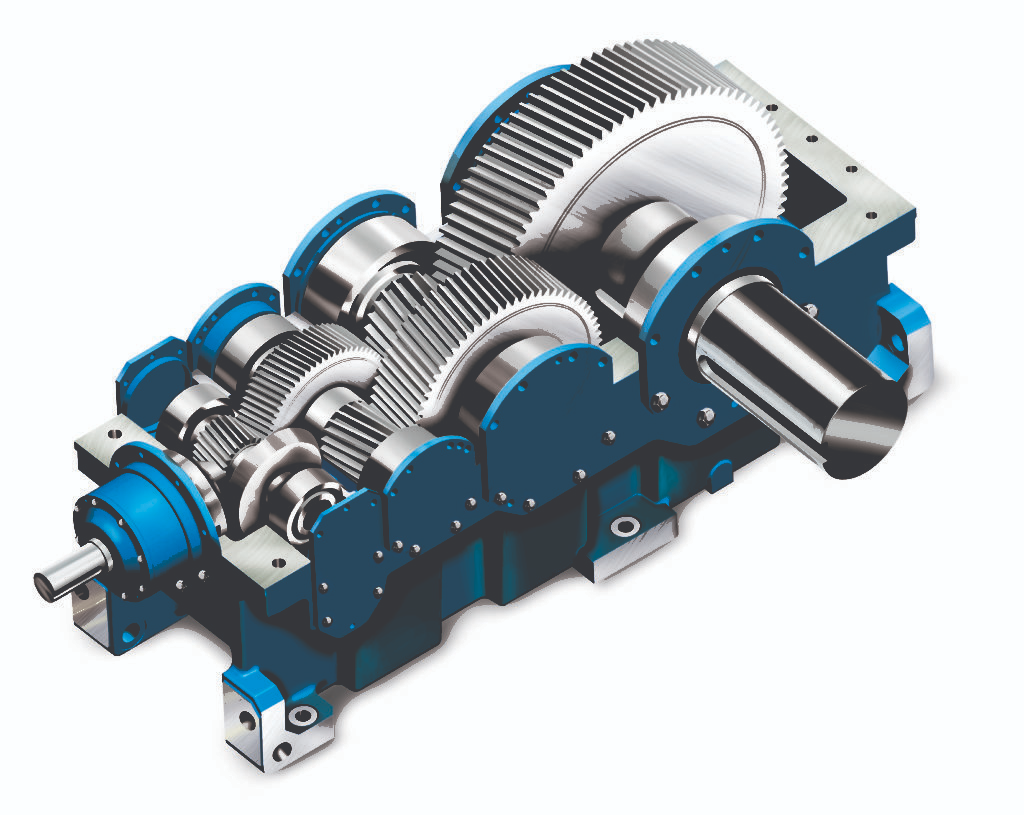

4. Planetary Gearboxes

Planetary gearboxes are operated in applications where high accuracy and torque are needed. They are generally used in aerospace, robotics, and machine tools.

Planetary gearboxes are compact and present a high gear reduction percentage in a limited space. They are also highly efficient and can manage heightened power loads. Planetary gearboxes have a remarkable design allowing numerous gears to turn around a central sun gear.

The planets link with the sun and ring gear, producing an increased gear reduction ratio. The planetary gearbox’s compact configuration permits it to transfer a high torque level without taking up significant amounts of space.

5. Cycloidal Gearbox

Cycloidal gearboxes are used where a high gear reduction is critical and necessary with minimal to no backlash, according to Bombay gearbox dealers. They are commonly employed in printing presses, robotics, and material handling equipment.

Cycloidal gearboxes have an exceptional design that qualifies them to supply a high rate of accuracy and seamless operation. They also deliver elevated torsional stiffness, ideal for applications that demand accurate positioning.

Cycloidal gearboxes have a distinctive design that employs a cycloidal disc to convey power amidst the input and output shafts. The disc includes lobes that link with rollers, transferring power from the input shaft to the output shaft.

The unique arrangement of the cycloidal gearboxes allows it to reach a high gear reduction ratio with the tiniest backlash. This makes it quintessential for applications that demand accurate positioning and the bare minimum vibrations.

FAQs

1. What is an industrial gearbox and how does it work?

An industrial gearbox is a mechanical device used to transfer energy from one device to another and modify torque, speed, and direction. It works by using a system of gears to convert input from a motor into output for machinery. Industrial gearboxes are essential in heavy-duty applications where precision and power transmission are critical, such as in manufacturing, mining, cement, and power plants. They help improve efficiency, reduce wear and tear on equipment, and maintain operational stability in industrial processes.

2. What are the different types of gearboxes used in industries?

There are several types of gearboxes in industries, each designed for specific operational requirements. Common types include helical gearboxes, bevel gearboxes, planetary gearboxes, worm gearboxes, and spur gearboxes. Each type varies in gear arrangement, load capacity, and suitability for specific applications. For example, planetary gearboxes are compact and ideal for high torque in limited spaces, while helical gearboxes are preferred for smooth and quiet operations in conveyor systems and crushers.

3. How do I choose the right type of industrial gearbox?

Choosing the right type of industrial gearbox depends on several factors such as load characteristics, speed ratios, space constraints, and environmental conditions. It’s essential to understand the operational requirements of your machinery—whether it demands high torque, compact design, or continuous duty. Consulting with gearbox manufacturers or specialists can help ensure the best gearbox is selected for durability, efficiency, and performance.

4. What are the typical uses of different types of gearbox in industry?

Each type of gearbox serves a specific function based on its mechanical properties. For instance, worm gearboxes are commonly used in elevators and conveyors due to their self-locking ability. Helical gearboxes are often used in rolling mills and packaging machinery for high load applications. Bevel gearboxes are suitable for applications requiring a right-angle gear drive, like in mining and printing presses. Planetary gearboxes are widely used in robotics, mixers, and aerospace for compact and high-torque solutions.

5. What makes helical gearboxes ideal for industrial use?

Helical gearboxes are preferred in many industrial applications due to their efficiency, reliability, and quiet operation. They offer high load-carrying capacity and smooth power transmission, making them ideal for heavy-duty machinery. The angled teeth in helical gears allow gradual engagement, reducing noise and vibrations. These gearboxes are commonly found in conveyors, crushers, and extruders across multiple industries, including automotive, cement, and steel.

6. What are the advantages of planetary gearboxes in industrial machinery?

Planetary gearboxes offer high torque density in a compact form, making them suitable for space-constrained and high-performance machinery. Their design distributes load evenly across multiple gears, which increases durability and shock resistance. Commonly used in robotics, mixers, cranes, and packaging machines, planetary gearboxes deliver precise motion control and are highly efficient. Their versatility and performance under varying loads make them a popular choice in modern industry.

7. Are worm gearboxes suitable for high-torque applications?

Yes, worm gearboxes are suitable for high-torque applications, especially where compact size and self-locking capability are important. These gearboxes are typically used in material handling equipment, lifts, and conveyors. Their simple design and ability to handle high shock loads make them a cost-effective solution. However, due to higher friction, they may not be as energy-efficient as other gearbox types and are better suited for intermittent or low-speed operations.

8. What are the key differences between bevel and spur gearboxes?

Bevel gearboxes are designed for right-angle power transmission and are typically used in applications like printing presses, mining equipment, and machine tools. They feature conically shaped gears that allow shafts to intersect. Spur gearboxes, on the other hand, have straight-cut gears and are used in applications requiring high-speed and low-torque transmission. They are more efficient but generate more noise and are not ideal for high-load applications compared to bevel or helical gearboxes.

9. Why is it important to maintain industrial gearboxes regularly?

Regular maintenance of industrial gearboxes is crucial to ensure optimal performance, reduce downtime, and prevent costly breakdowns. Over time, gearboxes are subjected to wear, contamination, and lubrication breakdown. Scheduled inspections, oil changes, alignment checks, and monitoring for unusual vibrations or noise can significantly extend the life of the gearbox and enhance machinery reliability. A well-maintained gearbox also ensures energy efficiency and smooth operation of industrial systems.

Where to Find the Best Industrial Gearbox Manufacturers in India?

According to Bombay gearbox dealers, if you are searching for the best premium gearbox manufacturer in India, you should look no further than Santram Engineers. We are India’s most trusted industrial gearbox manufacturers with decades of expertise in the field.

For assistance regarding worm gearboxes, you can call us at +91-96247 39393 or write to us at sales@santramengineers.com