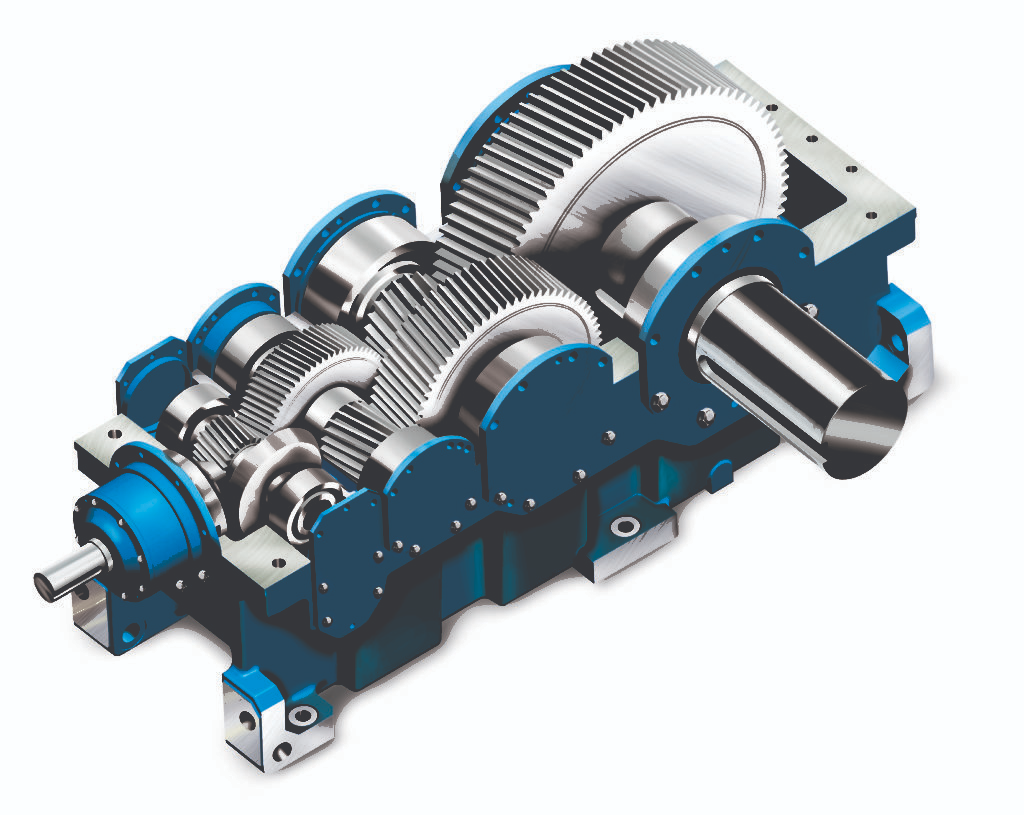

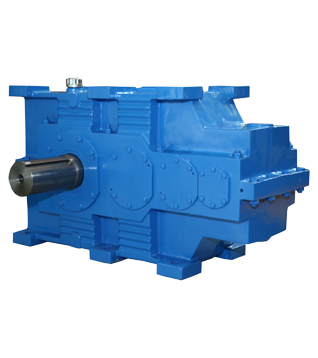

Heavy-duty helical gearboxes are the workhorses of industrial power transmission, facilitating the smooth transfer of torque and motion between shafts. These essential components find application in various industries, ranging from manufacturing to mining, where precision, efficiency, and reliability are paramount.

As a leading industrial gearbox supplier in India, understanding and addressing the most common complaints associated with helical gearboxes is crucial. Hence, this article delves into the intricacies of a helical gearbox, explores their primary applications, and offers detailed solutions to tackle the frequent issues encountered during their usage.

Common Complaints in Heavy-Duty Helical Gearboxes

Despite the numerous advantages offered by helical gearboxes, they are not immune to certain issues during operation. Understanding and addressing these common complaints is essential to ensure the optimal performance and longevity of gearboxes. Let’s elaborate on each point:

Noise and Vibration

Excessive noise and vibration during gearbox operation are frequent complaints. Although helical gears produce less noise compared to spur gears, improper gear meshing, misalignment, worn gears, or inadequate lubrication can still lead to increased noise levels and vibration. The noise can be disruptive to the workforce and may also indicate potential gear problems.

Solution:

- Regular maintenance and inspections: Schedule periodic maintenance to detect misalignments and inspect gears for signs of wear.

- Precision gear alignment: Ensure precise gear alignment to minimise gear meshing issues and reduce noise.

- Proper lubrication: Use high-quality lubricants and ensure adequate lubrication to reduce friction and vibration.

- Noise-damping materials and enclosures: Utilize noise-damping materials or enclosures to mitigate noise levels.

Gear Wear and Failure

As heavy-duty components, helical gearboxes are subject to substantial loads and stresses. Over time, these forces can lead to wear on the gear teeth, increasing the risk of gear failure. Insufficient lubrication, improper gear material, and inadequate heat treatment are common culprits for premature gear wear.

Solution:

- Regular inspection and monitoring: Conduct regular inspections to detect signs of wear on gear teeth.

- High-quality gear materials: Use high-quality gear materials and ensure proper heat treatment to enhance gear durability.

- Adequate lubrication: Properly lubricate gears to reduce friction and wear on gear surfaces.

- Address misalignment issues: Misalignment can cause uneven gear loading and wear; address any misalignment problems promptly.

Overheating

Overheating is a critical concern in helical gearboxes and can result from inadequate cooling or excessive loads. Elevated temperatures can accelerate wear on gears, bearings, and seals, compromising the gearbox’s overall performance and lifespan.

Solution:

- Proper ventilation and cooling systems: Ensure the gearbox housing has proper ventilation and cooling systems to dissipate heat effectively.

- Temperature monitoring: Regularly monitor temperature levels and employ temperature sensors for early detection of overheating issues.

- Enhanced cooling capacity: Improve cooling capacity by adding cooling fins or cooling fans to the gearbox.

Leaks and Oil Contamination

Oil leaks are a common problem in helical gearboxes, often caused by damaged seals or gaskets. Leaks can lead to lubricant loss, leading to insufficient lubrication and oil contamination, which, in turn, accelerates wear on gears and bearings.

Solution:

- Regular inspection and maintenance: Inspect and replace seals and gaskets as needed to prevent oil leaks.

- High-quality sealing materials: Use high-quality sealing materials to minimize the risk of leaks.

- Effective oil filtration: Implement effective oil filtration systems to prevent oil contamination and maintain lubricant quality.

Misalignment

Misalignment between the gearbox and connected equipment can cause uneven load distribution among the gear teeth, leading to accelerated wear and reduced performance.

Solution:

- Precision alignment: Utilize precision alignment tools and techniques during gearbox installation to ensure proper alignment with connected equipment.

- Regular alignment checks: Conduct regular alignment checks to maintain proper alignment throughout the gearbox’s operational life.

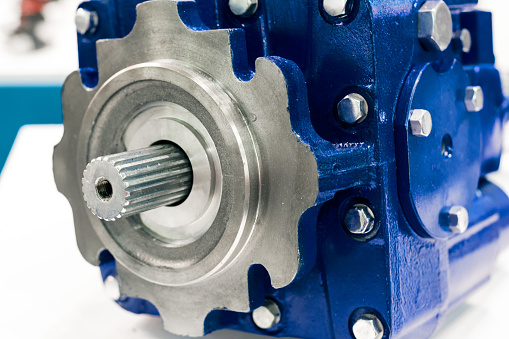

Bearing Issues

The bearings in a helical gearbox are crucial for supporting rotating shafts and gears. Damaged, misaligned, or inadequately lubricated bearings can lead to noise, vibration, and premature failure.

Solution:

- Regular inspection and lubrication: Regularly inspect and lubricate bearings to ensure their proper functioning and extend their lifespan.

- High-quality bearings: Use high-quality bearings suitable for the gearbox’s load and operating conditions.

Gearbox Housing Cracks or Damage

The gearbox housing must withstand substantial forces during operation. If not adequately designed or maintained, the housing can develop cracks or other structural damage, leading to oil leaks and compromised gearbox integrity.

Solution:

- High-quality materials and robust designs: Invest in helical gearboxes manufactured using high-quality materials and robust housing designs.

- Regular inspections and maintenance: Conduct regular inspections and maintenance to identify and address any housing-related issues.

Shaft and Keyway Problems

Issues such as shearing of keyways, shaft bending, or improper fit can disrupt smooth gear meshing and lead to operational problems.

Solution:

- Appropriate shaft materials and design: Use appropriate shaft materials and design to prevent keyway issues and ensure proper gear engagement.

- Regular inspections: Conduct regular inspections to identify early signs of shaft-related problems.

Backlash Issues

Excessive or inconsistent backlash between gear teeth can lead to noisy operation and reduce the gearbox’s accuracy and efficiency.

Solution:

- Proper backlash setting and maintenance: Properly set and maintain the backlash within specified tolerances during gearbox assembly.

Gear Chipping and Pitting

Chipping and pitting on gear surfaces are often caused by excessive loads, improper gear meshing, or inadequate lubrication. These surface defects can lead to accelerated wear, reduced gear efficiency, and potential gear failure.

Solution:

- Regular inspections: Conduct regular inspections to identify early signs of chipping and pitting.

- Proper lubrication: Ensure proper lubrication with high-quality oils and grease to reduce friction and prevent surface damage.

- Address misalignment issues: Misalignment can cause uneven gear loading and contribute to gear surface damage.

Gear Tooth Breakage

Gear tooth breakage is a severe complaint that can occur under heavy loads, shock loads, or when the helical gearbox is exposed to sudden impacts or overloads. This issue can lead to complete failure of the gearbox and significant downtime.

Solution:

- Adequate load analysis: Perform a thorough load analysis to ensure the gearbox is not subjected to loads beyond its design capacity.

- Improved material selection: Use high-strength gear materials and consider reinforcing gear teeth in critical areas.

- Shock load mitigation: Implement shock-absorbing components or torque limiters to reduce the impact of sudden loads on the gearbox.

Gear Tooth Scoring

Gear tooth scoring is the result of abrasive wear between gear teeth due to debris or foreign particles in the lubricant. Scoring can lead to premature gear failure if not addressed promptly.

Solution:

- Proper filtration and cleanliness: Implement effective oil filtration systems to prevent debris from contaminating the lubricant.

- High-quality lubricants: Use high-quality lubricants with excellent anti-wear properties to reduce the risk of gear tooth scoring.

- Regular lubricant analysis: Conduct regular lubricant analysis to monitor the condition of the gearbox lubricant and identify potential issues.

Inadequate Gearbox Ventilation

Inadequate helical gearbox ventilation can result in the buildup of heat and moisture, leading to lubrication issues and potential component failure.

Solution:

- Improved ventilation design: Enhance the gearbox housing’s ventilation system to promote efficient heat dissipation and prevent moisture buildup.

- Regular maintenance: Regularly clean and inspect ventilation components to ensure unobstructed airflow.

Corrosion and Rust

Corrosion and rust can occur when a helical gearbox is exposed to harsh environments or if the protective coatings on the gearbox components are compromised.

Solution:

- Corrosion-resistant materials: Use corrosion-resistant materials or protective coatings on critical gearbox components.

- Regular inspections and maintenance: Regularly inspect the gearbox for signs of corrosion and address any issues promptly.

Get the Best Quality Helical Gearboxes with Enhanced Performance

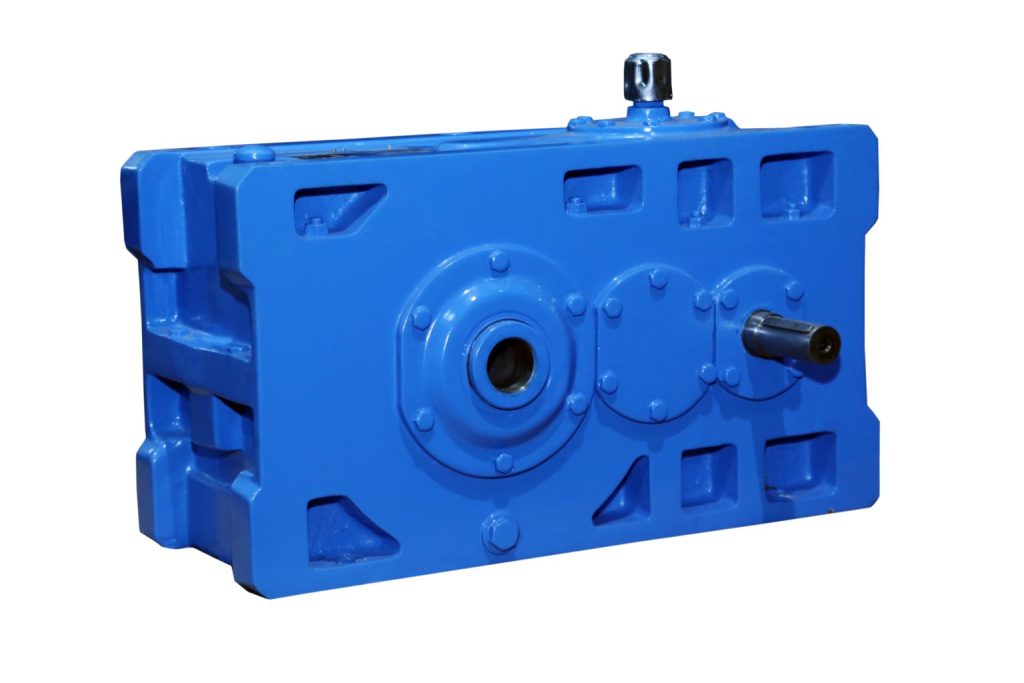

Discover the pinnacle of industrial power transmission with our high-quality helical gearboxes, meticulously crafted to deliver unmatched performance. At Santram Engineers, we pride ourselves on supplying a wide range of industrial gearboxes that excel in precision, efficiency, and durability, meeting the diverse needs of modern industries.

Experience the seamless transmission of torque and motion with our gearboxes, designed to withstand heavy loads and deliver increased load-carrying capacity. Say goodbye to noise and vibration issues, as our precision gear alignment and superior lubrication ensure smooth and quiet operation.

Trust our expertise and commitment to excellence, and equip your machinery with gearboxes that are engineered by a leading gearbox manufacturing company in India, Premium Transmission, that delivers products that surpass client expectations.

Embrace enhanced performance today and revolutionise your industrial processes. Contact us at +91 96247 39393 or email us at sales@santramengineers.com to get the best quality helical gearboxes tailor-made for your specific requirements. Let us drive your success with reliable, efficient, and durable gearboxes that never compromise on performance.