A lot of many organizations, for example, those in the paper, sugar, chemical, rubber, and concrete businesses, depending on the power of industrial gearboxes to finish their procedures. These ventures have a requirement for adaptable and compact gearboxes.

Gearbox makers center around making mechanically propelled machines that assistance to limit vitality costs and empower organizations to satisfy their procedures viable. The accompanying will clarify the highlights, advantages, and uses of the industrial gearboxes available today.

Worm Gearbox

- Qualities: Between axis shafts, this kind of gearbox gives a more noteworthy speed reduction ratio. Worm Gears are utilized to transmit control at 90 degrees.

- Specifications: The worm drive is furnished with a wheel that has a wider breadth. A worm screw networks with the teeth on the worm wheel’s peripheral area.

The worm resembles a screw while the wheel is like a segment of a nut. - Applications: Tuning instruments like guitars; lifts; entryways and conveyor belts.

Bevel Helical Gearbox

- Qualities: The Bevel Helical Gearbox gives a revolving movement between non-parallel shafts.

- Specifications: This gearbox has a bent arrangement of teeth on a cone-shaped surface.

- Applications: Mining or quarry industry.

Planetary Gearbox

- Qualities: This Planetary Gearbox is known for its persistence and veracity.

- Specifications: It comes with an empty or strong input, and there are different mounting alternatives, including foot, rib mounted, or shaft.

- Applications: Pencil sharpeners; 3D printing.

Skew Bevel Helical Gearbox

- Qualities: The skew bevel helical gearbox has magnificent unbending nature and quality.

- Specifications: This gearbox is noted for its steadfast, solid structure, consolidating two round and hollow helical phases of reduction with the skew pivot.

- Applications: Moving heavy load.

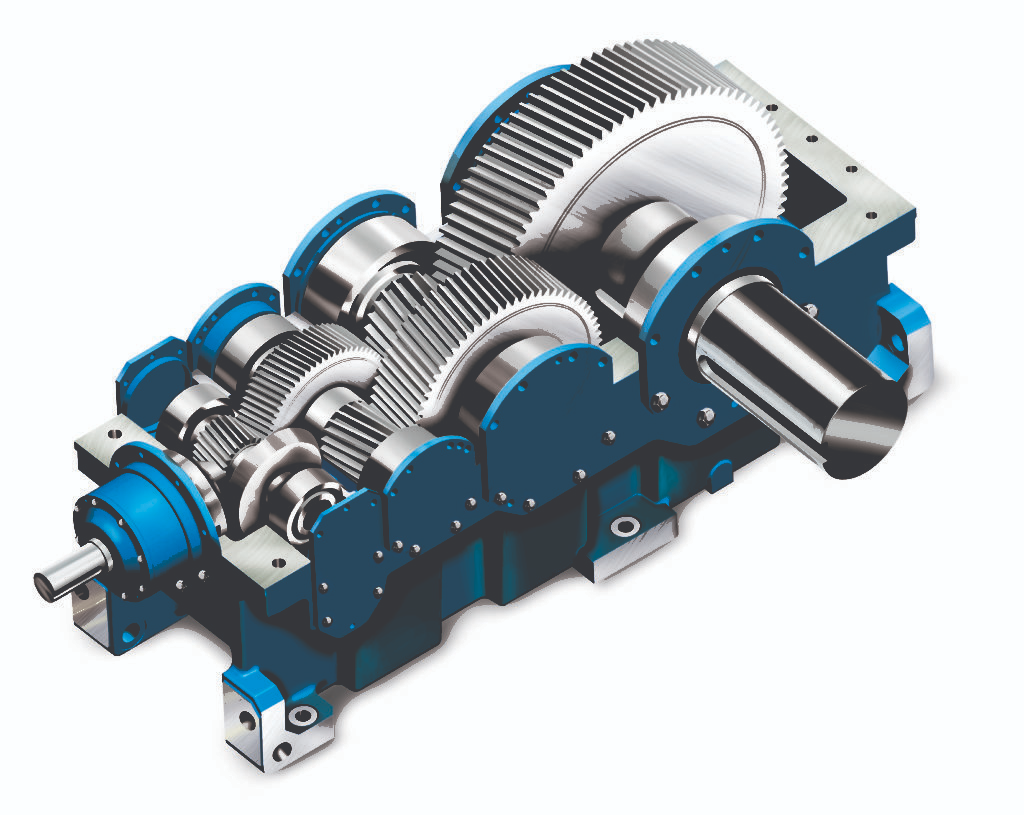

Coaxial Helical Inline Gearbox

- Qualities: Coaxial helical inline gears are known for their proficiency and quality.

- Specifications: The gears and shaft are put forth in case hardened, tempered steel, intended to accomplish negligible friction.

- Applications: mining, lifting, transportation, tank manufacture, construction, and so forth.

Gearbox Maintenance

Your Industrial Gearboxes are a venture into your future. It is essential to ensure this investment through legitimate upkeep. A gearbox ought to be consistently checked to ensure it is appropriately greased up and working as planned. It is additionally indispensable to keep all records of services and repairs.