If you are reading this blog, you are likely already past the “what is a gearbox” stage. You’re comparing suppliers, looking for a dependable product, and trying to reduce risk before placing an order. At this point, you want specifics: materials, build quality, ratios, load handling, lubrication reliability, delivery support, and how quickly the supplier can get the right unit into your plant with correct technical confirmation.

That is exactly where Santram Engineers stands out.

Santram Engineers is a leading distributor, dealer, and supplier of industrial gearboxes in India, known for providing robust, industrial-grade worm gearboxes built for long life and reliable service.

This guide goes deep into what matters when you are ready to buy: construction details, modular options, real application fit, what to ask before ordering, and why Santram Engineers is a safe choice when downtime is expensive.

Why Worm Gearboxes Are Still a Top Choice for Many Industries

Even with other gearbox types available, worm gearboxes remain a practical pick for many industrial lines because they deliver high torque at low output speeds in a compact package.

What You Get From Worm Gearboxes:

- High reduction ratios in a single stage, reducing complexity

- Smooth torque transfer for steady, controlled movement

- Compact design that suits space-limited installations

- Reliable performance for continuous duty when built correctly

In many plants, you’re not buying a gearbox for performance on paper. You’re buying stability: less vibration, fewer alignment issues, predictable speed reduction, and a unit that stays dependable across long shifts.

That’s why buying worm gearboxes from an experienced industrial supplier matters more than picking a low-cost unit with unclear materials.

What Makes Santram Engineers’ Worm Gearboxes Premium in Construction

Santram Engineers supplies products manufactured by Premium Transmission Limited, a leading name in the industrial gearbox industry. Their premium speed reducers are designed around rigidity, strength, and long service life. The construction details are not generic. They are built around proven material pairing and machining accuracy that directly affects wear, noise, efficiency, and lifespan.

1) Worm Shaft Built From Case-Hardening Steel

We use a worm made from high-quality case-hardening steel that is accurately generated, ground, and super-finished. That matters because the worm surface is under constant sliding contact.

When the worm surface is properly hardened and finished:

- Friction is lower

- Heat generation is lower

- Tooth wear is slower

- The gearbox stays stable longer under load

So when you choose worm gearboxes from Santram Engineers, you are choosing the right base for long-term meshing quality.

2) Worm Wheel With Phosphor Bronze Centrifugally Cast Rim

The worm wheel uses a phosphor bronze rim produced via centrifugal casting, with a substantial section welded to a rigid centre. It is pressed and keyed to the shaft.

This construction is important because the bronze quality and rim thickness affect:

- Load carrying capacity

- Wear resistance

- Heat dissipation

- Consistent torque output over time

In short, the worm and wheel pairing is a major reason buyers stick with Santram Engineers for worm gearboxes when reliability is the priority.

Bearings and Shafts: Where Many Gearboxes Fail First

A lot of gearbox failures start at the bearings or shafts, not the gears. Overhung loads, shock loads, pulley loads, and misalignment take a toll. Santram Engineers addresses these real-world conditions through design choices that support long service.

Dual-Purpose Bearings With Ample Capacity

Shafts are located on dual-purpose bearings of ample capacity, with a substantial margin on output shafts for accommodating overhung loads. This is a big deal for applications such as conveyors, mixers, and belt-driven systems.

What this gives you in practice:

- Less bearing overheating

- Better alignment stability under load

- Smoother running for long shifts

- Improved tolerance against industrial abuse

For buyers, this is a key signal. You’re not just buying worm gearboxes. You’re buying a drivetrain that stays stable under real loads.

Lubrication Reliability: Positive Lubrication at All Speeds and Both Directions

Lubrication is the silent killer of poorly built gearboxes. If lubrication flow is inconsistent, a gearbox may run fine for a few months and then rapidly degrade. Santram Engineers offers worm gearboxes with positive lubrication at all speeds, in either direction of rotation.

This brings three practical advantages:

- Better protection at low speeds, where splash lubrication may be weak in other designs

- Bidirectional reliability for setups that reverse rotation

- Low attention operation, apart from occasional oil checks

This matters for plants that run around the clock, where maintenance windows are tight. With Santram Engineers’ worm gearboxes, routine oil checks are typically the main ongoing requirement.

Modular Worm Gearbox Series: Flexible Options Without Complex Custom Builds

Santram Engineers supplies a modular series designed for broad application coverage while keeping parts common and interchangeable. This is a practical advantage when you want availability, consistent spares, and faster replacements.

Centre Sizes Available

- 4”, 5”, 6”, 7”, and 8” centres

Each size is based on a single universal case, giving a high degree of standard parts and interchangeability.

Mounting And Drive Options

- Under-driven

- Over-driven

- Vertical types

This helps match layout needs without forcing awkward couplings or redesign.

Double Extended Input Shaft

All units are fitted with a double extended input shaft. Handling can be changed by shifting only the fan and cowl from one end to the other.

For buyers, this reduces:

- Installation rework

- Downtime during changes

- Stock complexity for spares

And it makes Santram Engineers’ worm gearboxes a safer purchase for plants that anticipate line changes over time.

Ratio Coverage: 5:1 to 70:1 to Match Real Output Requirements

The modular worm series offers twelve standard ratios from 5/1 to 70/1. This wide ratio selection allows you to match speed and torque requirements without multi-stage systems.

Why that matters:

- Fewer moving parts

- Fewer alignment points

- Smaller footprint

- Easier installation and maintenance

If your machine needs slow speed and high torque, worm gearboxes often provide a clean, compact path to that output.

Materials and Housing: Built for Dust, Oil Tightness, and Alignment Stability

Santram Engineers supplies worm reduction gearboxes made from close-grain cast iron. This is chosen for strong rigidity, stable alignment, and industrial durability.

The housing can be operated in open environments due to its dust-proof and oil-tight properties, with construction that maintains ideal alignment.

This is critical in industries like cement, mining, and sugar, where dust and harsh conditions are normal.

So when you compare suppliers of worm gearboxes, housing quality is not a “nice to have.” It directly affects seal life, bearing life, and gear meshing.

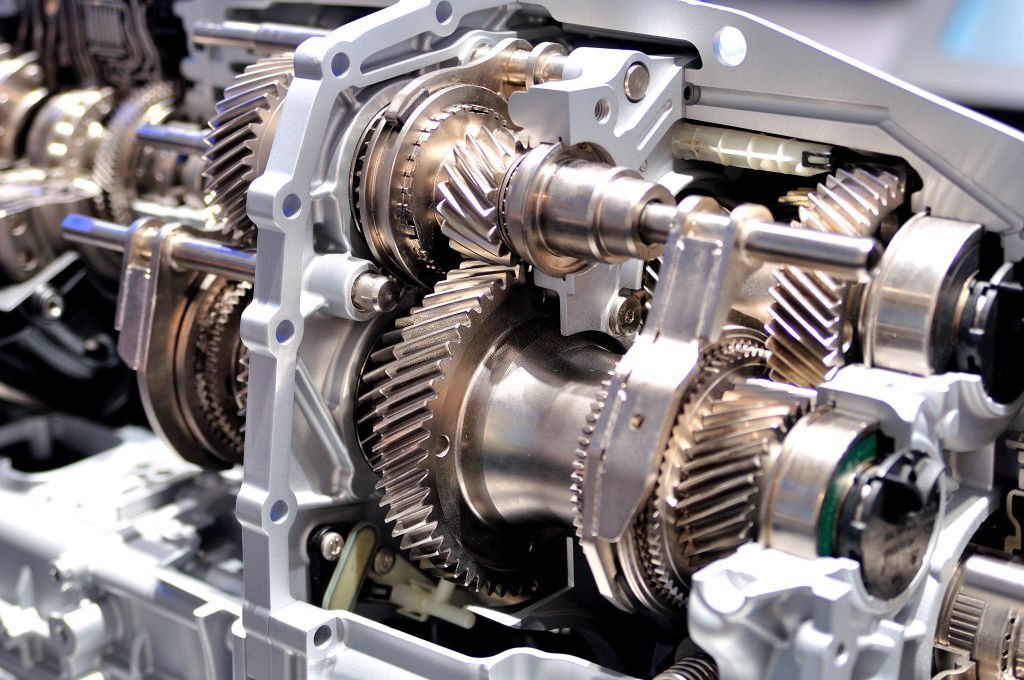

How Worm Gears Work and Why Precision Matters

Worm gears transmit motion through sliding contact between the worm and the wheel. That sliding contact means:

- Machining accuracy matters more

- Surface finish matters more

- Material pairing matters more

- Lubrication matters more

Santram Engineers focuses on these basics: hardened and finished worm, bronze wheel with substantial section, stable bearings, and positive lubrication. That combination directly targets the main failure causes of many low-grade worm gearboxes.

Right-Hand and Left-Hand Options for Layout Compatibility

Based on the requirement, worm gearboxes can be right-handed or left-handed. This flexibility reduces layout compromises and can save you from extra couplings or rework during installation.

If your plant design forces a specific rotation or layout direction, this option becomes a real purchase criterion, not a minor feature.

British and Indian Design Grades Applied

Santram Engineers applies British / Indian design grades. For buyers, this matters because it supports:

- Consistent design approach

- Predictable dimensions

- Smoother integration with standard industrial systems

When you’re buying worm gearboxes for replacement or expansion, predictable design alignment reduces commissioning time.

Industry Fit: Where Santram Engineers’ Worm Gearboxes Are Commonly Used

Santram Engineers supplies worm gearboxes for a wide set of industries and machine types including:

- Textile

- Chemicals

- Cement

- Sugar

- Agitators

- Mining

- Small ball mills

- Automobiles

- Industrial Equipment

- Oil / Petroleum

These are not light-duty areas. They involve long-running hours, load variation, and tough environments. This industry spread signals that Santram Engineers’ worm gearboxes are built for demanding use, not occasional operation.

Buyer Checklist: What to Confirm Before You Place an Order

If you’re close to purchase, this checklist helps you select the right worm gearboxes configuration and avoid wrong sizing.

1) Output Torque Requirement

Share your load details and duty cycle. High torque at low speed is common, but torque spikes and shock loads must be considered.

2) Required Output RPM and Ratio

Santram Engineers offers standard ratios from 5:1 to 70:1 in the modular series. Matching output RPM correctly avoids overheating and early wear.

3) Mounting Orientation and Space Constraints

Under-driven, over-driven, and vertical options help fit your layout. Provide installation constraints early.

4) Direction of Rotation and Reversal Needs

If your system reverses direction, the positive lubrication design becomes even more valuable. Confirm rotation and reversal frequency.

5) Overhung Load on the Output Shaft

If you have pulleys, sprockets, or belt loads, confirm the overhung load needs. Santram Engineers designs with an output shaft margin and strong bearing support.

6) Environment: Dust, Moisture, Temperature

Close-grain cast iron housing with dust-proof and oil-tight design supports open industrial environments, but it’s still smart to share real site conditions.

This is where working with experienced worm gears suppliers makes the buying process safer. You’re not guessing. You’re confirming.

Why Santram Engineers Is Trusted Among Worm Gears Suppliers in India

A gearbox purchase is not only about the unit. It’s also about the supplier’s ability to:

- Guide selection

- Confirm technical details

- Deliver on time

- Support after dispatch

Santram Engineers is known among worm gears suppliers because we combine a product range with practical industrial expertise. Buyers get support that prevents common mistakes like wrong ratio selection, wrong mounting, or ignoring overhung loads.

Supply Strength: Dealer Support and Fast Dispatch Matter

At this stage, you may have a shutdown window, a breakdown situation, or a project timeline. Supplier responsiveness is part of the product value.

Santram Engineers operates as a leading worm gearbox dealer in India and supports buyers with:

- Quick technical confirmation

- Order processing clarity

- Dispatch planning for industrial timelines

This helps reduce downtime risk, which is often worth far more than a small price difference.

Free Shipping Across India: Clear Cost Planning for Procurement Teams

Santram Engineers ships products across India with no extra delivery charges as part of the purchase process. For procurement and project teams, this improves cost predictability and makes approvals easier.

Where Industrial Gearboxes Fit in the Bigger Procurement Picture

Plants rarely run one gearbox type. Many operations use a mix of industrial gearboxes depending on machines and duty cycles. Working with a supplier that understands broader gearbox requirements helps you standardise sourcing and simplify spares planning.

Santram Engineers supplies industrial gearboxes alongside worm gearboxes, making it easier for plants to:

- Consolidate sourcing

- Align procurement standards

- Simplify vendor management

What Long Life and Reliable Service Look Like in Practice

Santram Engineers describes key features: high efficiencies, load-carrying capacity, long life, and reliable service. In practical terms, that shows up as:

- Stable output speed over time

- Fewer maintenance interventions

- Reduced unexpected breakdowns

- Lower replacement frequency

- Predictable performance under load

For buyers, this is the real goal. You don’t want a gearbox that works today. You want worm gearboxes that keep working through thousands of hours of industrial duty.

When Santram Engineers Is the Right Choice for Your Plant

Santram Engineers is a strong fit if you want:

- Premium build quality with hardened worm and bronze wheel construction

- Modular casing and interchangeability advantages

- Wide ratio coverage (5:1 to 70:1)

- Robust bearing and shaft support for industrial loads

- Positive lubrication that works in both directions

- Supplier-led technical confirmation before dispatch

If you are buying based on reliability and risk control, this is exactly why many industries in India choose Santram Engineers for worm gearboxes.

Request a Quote for the Right Worm Gearbox Setup

If you are finalising a purchase, the fastest way to avoid delays is to start with your operating details. Share your motor power, input RPM, target output speed, duty hours, mounting position, and any belt or pulley load. Add a quick photo of the existing unit’s nameplate if this is a replacement. With this, our team can help you pick the right model and ratio without guesswork.

Need a fast turnaround for a shutdown window or an urgent replacement? Tell us your dispatch location and timeline. We will confirm availability, share the commercial terms, and coordinate packing and logistics so your unit reaches you on schedule.

If you are sourcing for a new machine build, send your drawing or layout constraints. We will help you choose the best shaft orientation and connection type to match your assembly plan. And if you are managing procurement across multiple lines, ask for a consolidated proposal so you can standardise specs and simplify repeat orders.

Start by reaching out with your requirements today. The sooner we get the inputs, the sooner you can lock the order with confidence.

For any queries, you can call us at +91 96247 39393 or drop us an email to sales@santramengineers.com. We will be happy to assist you.