What are gears and gearboxes? A gear is a rotating machine part featuring cut teeth or cogs, which is supposed to mesh with another toothed part in order to transmit torque. In a layman’s language, gears are one of the most crucial parts of any motors and machine which help to increase the torque output by providing gear reduction and adjusting the direction of rotation. Two or more gears working together in tandem are called transmission or gearbox. Geared devices are more likely to change the speed, torque, direction of a power source.

Types of Gears and How They Are Different From Each Other?

Spur Gears

Spur gears are the most common products used in a series for large gear reduction. The teeth of spur gears are straight and are mounted in parallel on different shafts.

Its Advantages:-

- They offer constant velocity ratio

- They are highly reliable

- They are simple and easy in terms of making/ manufacturing

- They are mostly used to transmit large amount of power

Helical Gears

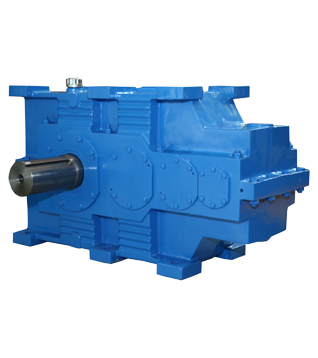

Unlike Spur gears, Helical gears and Helical Gearbox both have the capacity to conduct a smooth operation. The teeth on a helical gear cut at an angle to the face of the gear. So, during the process when two of the teeth start to engage, the contact is gradual- starting at one end of the tooth and maintaining contact as the gear rotates into full engagement. When it comes to transmissions, helical is the most commonly used gears and it even generates large amounts of thrust.

Its Advantages:-

- The angled teeth engage more gradually than spur gear teeth so that they can run more smoothly.

- Helical gears, as well as helical gearboxes, are highly durable and ideal for high-load applications.

- It has the capacity to transmit motion and power between either parallel or right-angle shafts.

Bevel Gear

Bevel gears are mostly used to change the direction of the shaft’s rotation. They have teeth in straight, spiral, hypoid shapes. Each one of a kind, for example, straight teeth have similar characteristics to spur gears while spiral operates the same as helical gears as they produce less vibration.

Its Advantages:-

- Bevel are such kind of gears that makes it possible to change the operating angle.

- The variety of teeth on each wheel allows mechanical advantage to be changed.

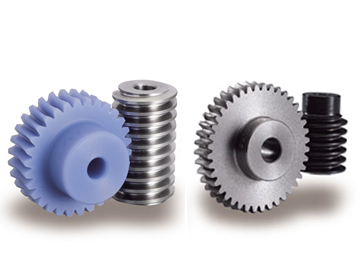

Worm Gears

Most of the Industrial Gearbox Suppliers prefer providing Worm Gears to their valuable clients as it is used for large gear reductions. The setup is designed in such a way that setup can turn the gear, but the gear cannot turn the worm. The angle of the worm is shallow and as a result, the gear is used in conveyor systems for brake or emergency stops.

Its Advantages

- Worm Gears operate more silently and smoothly

- They are self-locking

- They occupy less amount of space

- They have good meshing effectiveness and thus, can be used to reduce speed and increase torque.

Why Helical Gears?

Helical gears are cylindrical gears whose teeth are not parallel to the axis of rotation. The teeth are angled and appear as a segment of a helix which makes it transmit power between parallel or right angle axes. The main difference between a helical gearbox and others is that the teeth form a helix and have the potential to run more quietly. Another advantage of using these gears are that they will have more capability to transmit load between two parallel shafts as compared to the similar module and equivalent width of spur gears. And of course, there will be less wear and tear as the load will be distributed between several teeth.

Its Application

Most of the reputable Industrial Gearbox Suppliers suggest helical gears to work under heavy load efficiency and of course when we need silent operation such as automotive applications.

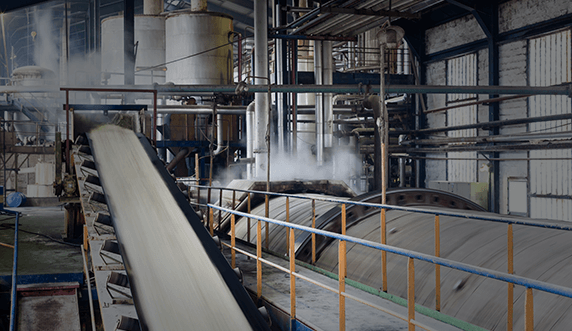

- Fertilizer industries, printing industries, and earth-moving industries

- Steel, rolling mills, power, and port industries

- Textile industries, plastic industries, food industries, conveyors, elevators, blowers, compressors, oil industries & cutters.

In addition to the above applications, there are many others. The overall application of helical gears and helical gearboxes is widespread. Keep an eye on the space to know more.

FAQs About Helical Gears

What is a helical gear?

A helical gear is a type of cylindrical gear with teeth cut at an angle (helix) to the axis of rotation. This design enables gradual engagement between gear teeth, resulting in smoother, quieter, and more efficient power transmission compared to spur gears.

What are the main advantages of helical gears?

The advantages of helical gear systems include quiet operation, high load-carrying capacity, reduced vibration, and greater durability. These qualities make them ideal for high-speed and high-power applications where smooth and reliable performance is essential.

Where are helical gears used in industrial applications?

Helical gears are used in various industries, including automotive transmissions, conveyor systems, elevators, steel plants, and packaging machinery. Their efficiency and quiet operation make them perfect for applications that demand consistent, high-performance power transfer.

What are the benefits of helical gears over spur gears?

The benefits of helical gears include smoother motion due to gradual tooth engagement, higher torque transmission, better efficiency, and quieter operation. They also offer more tooth contact, which helps distribute the load more evenly and increases lifespan.

What is the difference between helical gears and bevel helical gears?

Bevel helical gears combine the features of bevel and helical gears. While standard helical gears are used for parallel or crossed shafts, bevel helical gears are designed for applications where power needs to be transferred between intersecting shafts, offering enhanced strength and smooth meshing.

What makes helical gears suitable for high-load applications?

Helical gears are designed with angled teeth that allow multiple teeth to engage simultaneously. This load distribution minimizes wear and improves torque handling, making them suitable for high-load and high-speed applications.

Can helical gears operate at high speeds?

Yes, helical gears can efficiently operate at high speeds due to their smooth and gradual tooth engagement. This reduces noise and vibration, making them ideal for high-speed gearboxes and motor-driven systems.

What industries rely heavily on helical gear applications?

Helical gear applications are found in industries such as manufacturing, mining, oil and gas, cement, and food processing. Their adaptability to different torque and speed requirements makes them a popular choice in heavy-duty industrial machinery.

What are the typical uses of helical gears in daily machinery?

Common helical gear uses include car gearboxes, printing presses, elevators, conveyor belts, and turbine drives. They ensure efficient power transmission and quiet performance in both industrial and consumer-grade machinery.

Why are helical gears preferred for quiet operations?

Due to their angled tooth design, helical gears engage gradually rather than all at once, which reduces impact, vibration, and noise. This makes them highly preferred in applications requiring low-noise environments, such as HVAC systems and precision instruments.