In industrial settings, the reliability and efficiency of machinery depend significantly on the gearbox technology in use. Helical gears, a popular choice in many industries, play a pivotal role in ensuring smooth, quiet, and efficient power transmission across a wide range of applications. Their unique angled tooth design helps provide better tooth engagement, leading to superior performance in heavy-duty machinery.

Whether you’re looking to design an assembly line, a conveyor system, or a fan system, understanding helical gearboxes is critical to selecting the correct gearbox layout. When choosing the ideal gearbox for your system, the layout and type of gear, such as inline or parallel shaft, are central to optimising space, torque, energy efficiency, and longevity.

The two most commonly used helical gear configurations are inline and parallel shaft. Each offers its own set of advantages and trade-offs. This article will explore both configurations in depth, comparing their designs, strengths, and ideal applications to help you determine which option is best suited for your specific needs.

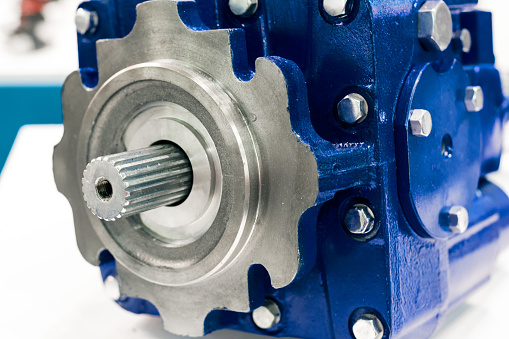

What Are Helical Gearboxes?

A helical gearbox is a mechanical device that uses helical gears to transmit power between shafts. Unlike spur gears, which have straight teeth, these gears have teeth cut at an angle. This angular design offers several key advantages:

- Smoother engagement: The tooth engagement starts gradually, which reduces shock loading and allows smoother power transmission.

- Higher load capacity: Since multiple teeth are in contact at once, the load is distributed more evenly, which means helical gears can handle higher torque than spur gears.

- Quieter operation: The gradual tooth engagement also reduces vibration and noise, making them ideal for applications where noise reduction is crucial.

Why Helical Gearboxes Are Preferred

Helical gearboxes are typically favoured in heavy-duty applications due to their robust and efficient design. Some of the industries that use these gearboxes include:

- Material handling: Conveyors and elevators

- Industrial machinery: Mixers, crushers, and mills

- Automation: Packaging lines, robotics, and manufacturing systems

- HVAC systems: Fans and blowers

Thanks to their high efficiency, low noise, and superior torque handling, helical gears are a popular choice for demanding, high-performance industrial applications.

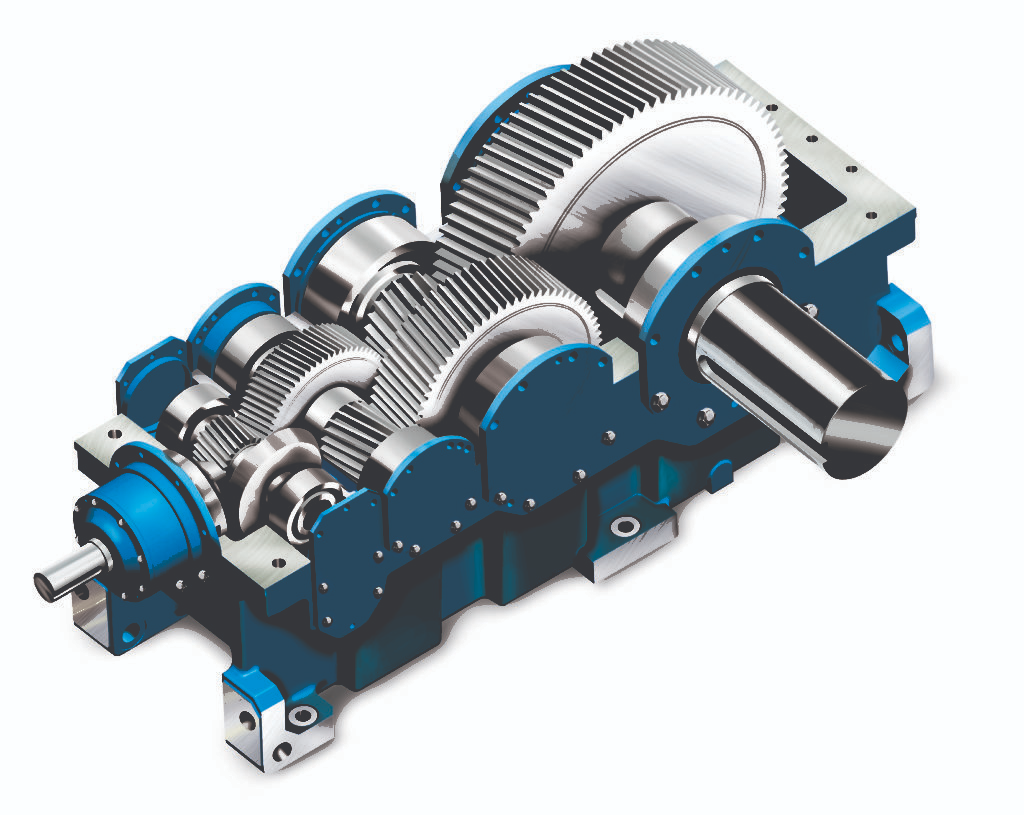

Inline Helical Gearbox: Configuration and Working Principle

Layout and Power Flow

In an inline helical gearbox, both the motor and output shafts are aligned along the same central axis. The power flows in a straight line through the gearbox, which makes these gearboxes simpler to design and install. The straightforward nature of the inline configuration means that these gearboxes are often compact, making them ideal for applications with limited installation space.

Key Engineering Traits

Inline Helical Gearboxes have several important design features that make them a good choice for many industrial applications.

- Efficient Power Transmission: Inline gearboxes make use of helical gears that provide smooth engagement. This efficient tooth engagement results in reduced energy loss, allowing for higher overall system efficiency.

- Low Noise and Vibration: One of the standout features of inline gearboxes is their ability to operate quietly, a result of the gradual tooth engagement in helical gears. This is particularly important in industries like packaging, food production, and pharmaceuticals, where noise control is critical.

- Moderate to High Torque: Inline gearboxes are designed to handle moderate to high torque levels, depending on their design. They are well-suited for applications with consistent load demands, but they may not handle extreme shock loading or very high radial loads as well as other types of gearboxes.

Typical Applications

Inline helical gearboxes are used in a wide range of industries, including:

- Conveyor Systems: They are used in material handling systems like belt conveyors, screw conveyors, and bucket elevators.

- Pumps: Inline gearboxes are ideal for driving pumps in various industrial processes, including water treatment, oil and gas, and chemical production.

- Fans and Blowers: Many HVAC and ventilation systems rely on inline helical gearboxes for efficient air circulation.

- Packaging Machinery: They help ensure consistent motion control in packaging equipment, ensuring speed regulation and precise operations.

- General Automation: Any machinery requiring precise motion control and reliability can benefit from an inline helical gearbox.

Strengths and Limitations

Strengths:

- Compact Design: Inline gearboxes take up less space due to their straight-line shaft alignment, making them a good fit for compact applications.

- Quiet Operation: The design and gradual tooth engagement result in quieter performance, a valuable trait for many industrial settings.

- High Efficiency: The efficient tooth engagement reduces friction and minimises energy losses, offering a high-efficiency operation.

Limitations:

- Limited Ability to Handle High Radial Loads: Inline gearboxes are not well-suited for handling heavy radial loads compared to parallel shaft designs.

- Limited Gear Ratio Options: Some inline designs may have a narrower range of available gear ratios, which could limit flexibility in certain applications.

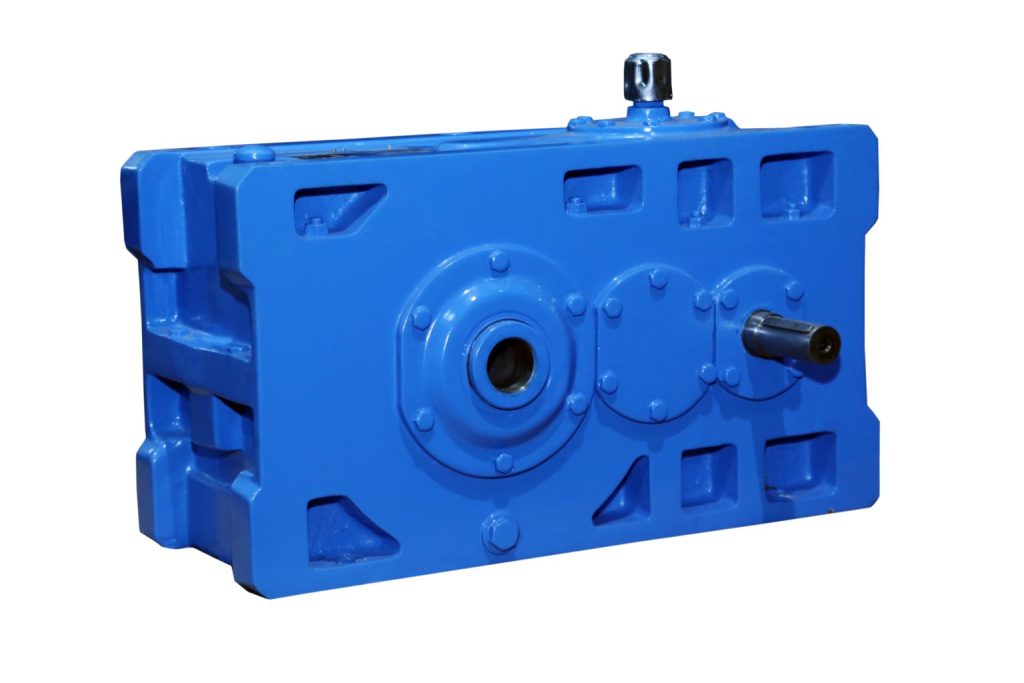

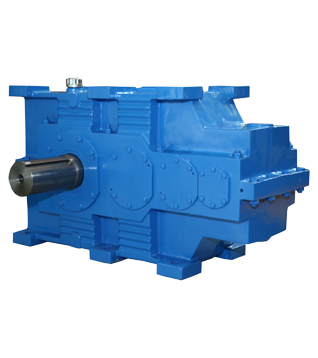

Parallel Shaft Helical Gearbox: Configuration and Working Principle

Layout and Power Flow

In a parallel shaft helical gearbox, the input and output shafts run parallel to each other but are offset. Power transmission in this configuration occurs through multiple stages of helical gears. These multiple stages allow for higher torque multiplication and the ability to handle more substantial loads compared to inline systems.

The parallel shaft design allows flexibility in mounting options, which is essential for complex systems where space and orientation matter.

Key Engineering Traits

Parallel shaft helical gearboxes are known for their ability to handle high torque loads and their design flexibility.

- High Torque Output: Parallel shaft helical gearboxes can deliver significantly higher torque output compared to inline designs, making them ideal for heavy-duty applications like crushers and mills.

- Ability to Handle Radial Loads: Due to their larger shaft sizes and bearing support, parallel shaft gearboxes excel at handling high radial loads, which are typically seen in conveyor systems, crushers, and mixers.

- Wide Gear Ratio Range: With multiple gear stages, parallel shaft gearboxes offer a broad range of gear ratios, which means they can accommodate a wider variety of speed and torque requirements.

Typical Applications

Parallel shaft helical gearboxes are commonly found in industries that require robust power transmission and can handle large loads. These applications include:

- Bulk Material Handling: In heavy-duty conveyors, elevators, and crushers in mining, cement, and steel industries.

- Crushers and Mills: Heavy equipment such as crushers, grinders, and mills requires gearboxes that can handle very high torque levels and radial loads.

- Cooling Towers: For large industrial cooling systems in chemical plants and power stations.

- Agitators: Used in chemical, pharmaceutical, and food industries for mixing fluids and solids under high torque conditions.

- Heavy Conveyors: In industries like cement, sugar, and steel, parallel shaft gearboxes help transport materials over long distances.

Strengths and Limitations

Strengths:

- Superior Torque Handling: The design of parallel shaft gearboxes allows them to handle high radial and axial loads, making them suitable for very heavy-duty applications.

- Flexible Mounting Options: These gearboxes can be mounted in a variety of positions to accommodate different plant layouts.

- Durability: Parallel shaft helical gearboxes are known for their durability, especially in high-duty cycle applications with high shock loading.

Limitations:

- Larger Footprint: Due to their offset design and multiple gear stages, these gearboxes are larger than inline models and require more installation space.

- Higher Initial Costs: The added complexity of the design often means they come with a higher upfront cost compared to inline models.

Inline vs Parallel Shaft Helical Gearboxes: Technical Comparison

Feature |

Inline Helical Gearbox |

Parallel Shaft Helical Gearbox |

| Shaft Orientation | Aligned on the same axis | Parallel and offset shafts |

| Torque Handling | Moderate to high torque | High to very high torque |

| Radial Load Handling | Limited | Excellent, supports heavy radial loads |

| Gear Ratio Range | Moderate, narrower in some cases | Wide range of ratios |

| Space Requirement | Compact and space-efficient | Larger footprint, requires more space |

| Mounting Flexibility | Limited flexibility in mounting options | High flexibility in mounting |

| Applications | Conveyors, pumps, fans, and general automation | Crushers, mills, heavy conveyors, agitators |

| Maintenance | Easier maintenance due to compact design | Requires more space for maintenance access |

| Cost | Lower initial cost | Higher initial cost |

How to Choose the Right Helical Gearbox for Your Application

Assess Load Cycles and Torque Demands

Consider the type of loads your system will handle. Steady loads require less attention, but if your application faces shock loading (like in crushers or mills), you need a gearbox that can handle those sudden surges in force. For high-torque, high-shock applications, parallel shaft gearboxes are your best option.

Evaluate Installation Space and Layout

- Inline gearboxes are perfect for installations where space is at a premium and where simple alignment is crucial.

- Parallel shaft gearboxes are suited for layouts where offset shafts provide flexibility, but space is available for larger units.

Consider Duty Cycle and Operating Environment

If your plant runs 24/7, you’ll need a gearbox that can withstand continuous operation without overheating or failing prematurely. Parallel shaft gearboxes offer better durability for heavy-duty, continuous applications.

Factor in Maintenance and Access

Maintenance can be a crucial part of the decision-making process. Inline gearboxes typically offer easier maintenance due to their compact nature. In contrast, parallel shaft gearboxes may require more planning for servicing.

Look at Efficiency and Energy Costs

Inline gearboxes often have better energy efficiency due to their more compact design, which reduces friction losses. However, parallel shaft gearboxes can also maintain high efficiency, particularly in demanding applications where torque and load handling are more critical than energy use.

When Inline Helical Gearboxes Are the Better Choice

Inline gearboxes are ideal for applications such as:

- Light to medium-duty conveyors

- Small mixers and stirrers

- Packaging machines

- Fan and blower drives

These setups require a compact and quiet gearbox capable of handling moderate torque. The ease of integration and quiet operation are key factors that make inline helical gearboxes the preferred choice.

When Parallel Shaft Helical Gearboxes Are the Better Choice

Parallel shaft helical gearboxes shine in:

- Heavy-duty conveyor systems

- Crushers and mills

- Cooling tower drives

- Agitators in chemicals and pharmaceuticals

Their ability to handle high torque, extreme shock loads, and heavy radial loads makes them ideal for these applications, where performance under stress is critical.

How Premium Transmission Designs Helical Gearboxes for Reliability

When you choose a Premium gears dealer, you benefit from a gearbox that has been meticulously engineered for long-term performance. Premium Transmission focuses on the following aspects when designing their helical gears:

- Material Selection: Only premium alloy steels and other durable materials are used to ensure maximum strength and wear resistance.

- Heat Treatment: Gears undergo controlled heat treatment to improve surface hardness and internal toughness.

- Precision Machining: All gears are precision machined and ground for accurate tooth contact and quiet operation.

- Bearings and Seals: Premium bearings and seals are carefully selected to reduce friction, prevent contamination, and extend the gearbox’s lifespan.

- Testing and Quality Control: Each industrial gearbox undergoes rigorous testing to meet performance standards, ensuring reliability in the toughest environments.

Why Buying From an Authorised Premium Gears Dealer Matters

When purchasing helical gearboxes, always opt for an authorised Premium gears dealer like Santram Engineers. Here’s why:

- Genuine Parts: Ensure your gearbox contains authentic components designed for optimal performance.

- Technical Support: Get expert guidance on selecting the right gearbox, sizing, and installation advice.

- Faster Delivery: Santram Engineers provides quick delivery times to reduce machine downtime.

- Warranty & Service: Products come with a warranty, and we offer fast service after your purchase.

- On-Site Support: Our team offers on-site commissioning, troubleshooting, and support for seamless installation.

Connect With India’s Most Trusted Premium Transmission Dealer – Santram Engineers

When it comes to selecting the right gearbox for your industrial needs, you deserve a partner that understands your unique requirements and delivers unmatched quality. Santram Engineers is India’s most trusted Premium Transmission dealer, offering industry-leading helical gearboxes and expert guidance on gearbox selection, installation, and maintenance. With years of experience in providing top-notch solutions for diverse industries, we ensure that every gearbox we provide is built for durability, efficiency, and long-term reliability.

By choosing Santram Engineers, you gain access to:

- High-quality, authentic Premium Transmission products

- Expert technical support for optimal gearbox sizing and selection

- Timely delivery and on-site commissioning services

- Warranty-backed reliability and after-sales support

Speak with Santram Engineers at +91 96247 39393 or email us at sales@santramengineers.com to ensure your industrial applications run smoothly and efficiently. Let us help you make the right choice for sustained operational success and cost savings.

Also Read: