In mechanical engineering, selecting the right gear type is essential to ensuring smooth and efficient power transmission. Among the many types of gears available, worm gears and helical gears are two commonly used in various industrial applications. Although both serve the function of transferring motion and torque, their structures, operating principles, efficiency levels, and use cases vary significantly.

In this comprehensive gear comparison, we will explore the difference between worm and helical gear systems, including their specifications, features, and best-use scenarios to help you make an informed decision.

What Are Worm Gears?

Worm gears consist of a screw-like component known as the worm, which meshes with a toothed wheel called the worm wheel. This configuration results in high torque transmission with minimal space usage. Worm gears are primarily used when large gear reductions are required.

Explore our range of worm gears

Worm Gear Features:

- High reduction ratios

- Self-locking capability in certain designs

- Smooth and quiet operation

- Compact design

Worm Gear Specifications:

- Typical gear ratio: 20:1 to 300:1

- Efficiency: 50% to 90% depending on design and lubrication

- Applications: Lifts, conveyors, automotive steering systems, gearboxes, hoists

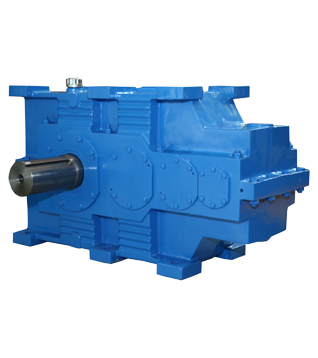

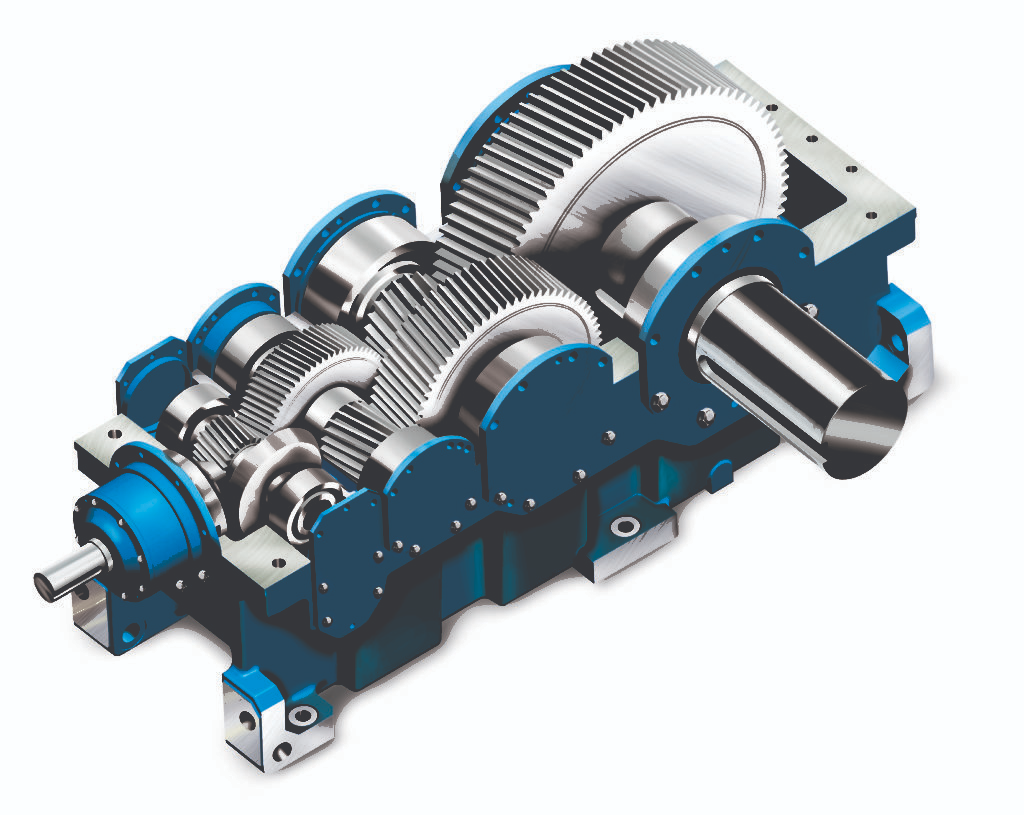

What Are Helical Gears?

Helical gears are cylindrical gears with teeth cut at an angle (helix) to the axis of rotation. This angled tooth design allows for gradual engagement, resulting in smoother and quieter operation compared to straight-cut gears. Helical gears can transmit motion between parallel or non-parallel shafts.

View our precision helical gearboxes

Helical Gear Features:

- High load-carrying capacity

- Quiet and smooth operation

- Can transmit motion at various angles

- Longer life due to gradual engagement

Helical Gear Specifications:

- Typical gear ratio: 3:2 to 10:1

- Efficiency: 90% to 98%

- Applications: Automotive gearboxes, compressors, turbines, conveyors, machine tools

Worm Gears vs Helical Gears: Key Differences

Understanding the worm gears vs helical gears debate requires a breakdown of their unique characteristics and how they affect performance, cost, and maintenance.

1. Gear Orientation and Geometry

- Worm Gears: Use a worm (screw-like gear) that meshes with a worm wheel. Shaft axes are typically at 90 degrees.

- Helical Gears: Use slanted teeth and can be mounted on parallel or crossed axes.

2. Speed Reduction and Torque

- Worm Gears: Ideal for high torque and large speed reduction in compact spaces.

- Helical Gears: Efficient for moderate speed reductions and are used when high precision and lower torque are sufficient.

3. Efficiency

- Worm Gears: Generally lower efficiency due to sliding contact.

- Helical Gears: Higher efficiency due to rolling contact between teeth.

4. Self-Locking Capability

- Worm Gears: Can be self-locking, useful for hoists and lifts.

- Helical Gears: Cannot self-lock.

5. Noise and Vibration

- Worm Gears: Operate more quietly, even under heavy loads.

- Helical Gears: Quiet, but not as much as worm gears in similar load conditions.

6. Maintenance and Lubrication

- Worm Gears: Require special lubricants due to higher friction.

- Helical Gears: Easier to maintain with standard lubrication.

Gear Comparison Table

| Feature | Worm Gears | Helical Gears |

|---|---|---|

| Tooth Design | Screw-like | Helically cut |

| Shaft Orientation | Non-parallel (90 degrees) | Parallel or crossed |

| Gear Ratio Range | 20:1 to 300:1 | 3:2 to 10:1 |

| Efficiency | 50% to 90% | 90% to 98% |

| Noise Level | Very Low | Low |

| Self-Locking Capability | Yes | No |

| Common Applications | Hoists, Lifts, Gear Reducers | Gearboxes, Machinery, Tools |

| Maintenance Requirements | High | Moderate |

| Cost | Moderate to High | Moderate |

When to Choose Worm Gears

Choose worm gears when:

- You need a high gear reduction ratio in a compact space

- Self-locking is required (e.g., elevators or conveyors)

- Noise must be kept at a minimum

- Space constraints limit gear arrangement

When to Choose Helical Gears

Choose helical gears when:

- You need high efficiency and load capacity

- Smooth, quiet operation is important

- The gear system must handle high speeds

- Long operational life is a priority

Types of Gears in Industrial Use

In addition to worm and helical gears, other types of gears include:

- Spur Gears: Simple, straight-cut gears

- Bevel Gears: Used for intersecting shafts

- Planetary Gears: Compact and high-torque systems

- Hypoid Gears: A variation of spiral bevel gears with offset shafts

Understanding the differences between these gears helps in selecting the right system for your machinery.

Get Expert Advice on Choosing the Right Gear Today

The difference between worm and helical gear setups lies in their performance under specific mechanical demands. If your application demands high torque with a compact footprint and occasional self-locking, worm gears are ideal. However, for efficient, high-speed performance with excellent load handling, helical gears are the better option.

Both types have their place in modern mechanical systems, and your choice should be based on operational requirements, budget, and design limitations.

For expert guidance on choosing between worm gears vs helical gears, contact Santram Engineers, India’s trusted provider of precision-engineered transmission solutions.