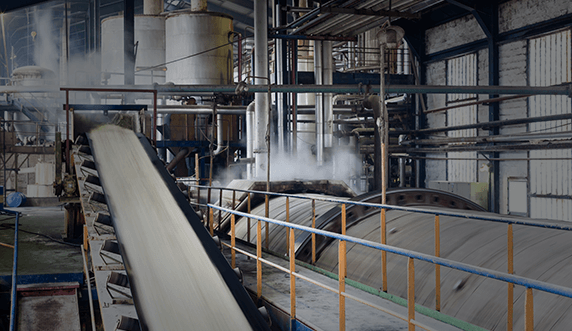

Cement manufacturing is one of the most energy-intensive industries in the world. Every stage, from crushing limestone to grinding clinker, depends on precision-driven, heavy-duty machinery. To keep these massive systems running seamlessly, gearboxes and geared motors play a central role.

However, cement plants often face challenges such as high mechanical stress, dust, vibration, and heat. These harsh conditions demand robust and reliable power transmission systems that can ensure consistent performance.

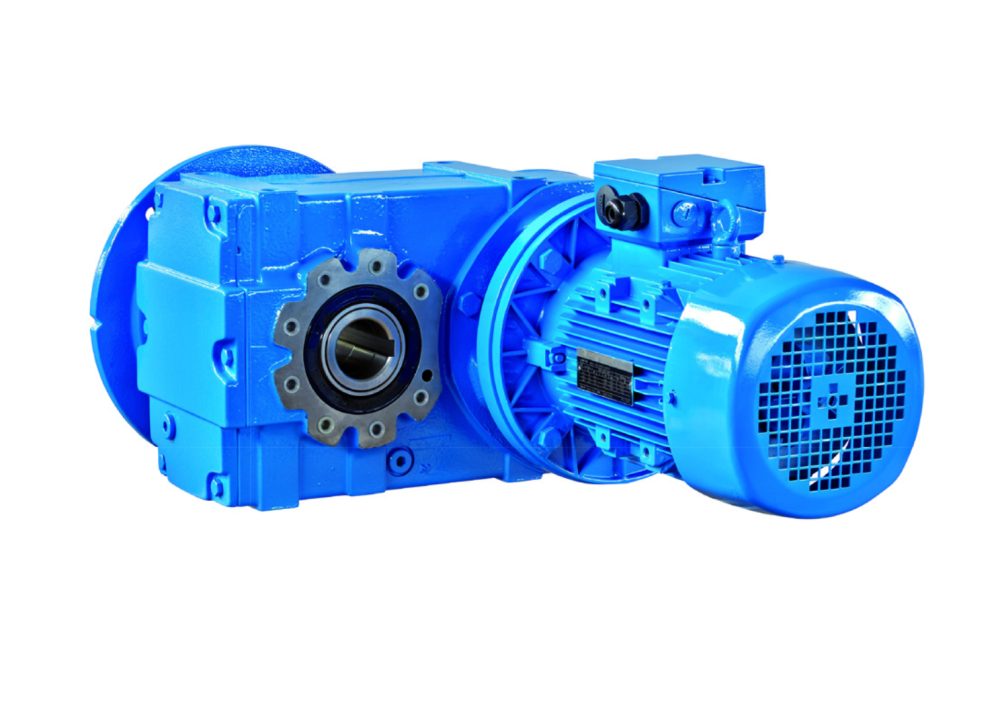

That’s where Santram Engineers (SEPL) steps in, providing industrial gearboxes and geared motors for cement plants that deliver exceptional torque, speed control, and efficiency across the operations.

Overview of Cement Plant Operations

Cement production involves several complex stages:

- Raw material extraction and crushing

- Raw meal grinding

- Clinker production in rotary kilns

- Cement grinding and packaging

Each stage uses massive rotating equipment, conveyors, and mills, all powered by motors and gearboxes. Without efficient gear transmission, these operations would consume more energy and suffer frequent breakdowns.

Gearboxes ensure that power from electric motors is transmitted efficiently to different plant equipment, adjusting speed, torque, and direction as required.

What Is a Gearbox for a Cement Plant?

A gearbox for a cement plant is a mechanical device that transmits power from a motor to machinery by adjusting torque and rotational speed. In cement plants, these gearboxes handle enormous loads, withstand abrasive environments, and run continuously for long hours.

They control:

- Speed reduction — ensuring the right pace for each operation.

- Torque amplification — providing the power required for heavy-duty machinery.

- Direction change — aligning rotational movement for plant components.

Types of Industrial Gearboxes Used in Cement Plants

Different applications in a gearbox in a cement plant require specific gearbox types:

- Helical Gearboxes: Known for smooth and quiet operation, used in conveyor systems, crushers, and feeders.

- Planetary Gearboxes: Offer compact design with high torque density, ideal for mills, kilns, and mixers.

- Bevel Gearboxes: Used for angular power transmission in confined spaces.

- Worm Gearboxes: Provide high torque at low speeds, suitable for conveyors and small lifts.

Santram Engineers supplies Premium Transmission gearboxes, engineered to perform efficiently under demanding cement plant conditions.

Applications of Gearboxes and Motors in Cement Plants

Raw Material Handling

The first stage of cement production involves moving limestone and clay from quarries to crushers and mills.

- Belt Conveyors: Use helical or worm gearboxes to control speed and manage heavy loads over long distances.

- Crushers and Mills: Require planetary gearboxes for torque-intensive crushing operations. These ensure smooth and reliable motion even under high shock loads.

Kiln Drive and Clinker Production

The kiln is the heart of every cement plant. It operates at extremely high temperatures, rotating continuously to convert raw meal into clinker.

- Rotary Kiln Drives: Employ high-torque helical or planetary gearboxes to manage precise speed control and rotation.

- Cooler Drives and Fans: Use geared motors to maintain airflow and temperature control.

Grinding and Milling Systems

Grinding the clinker into fine powder demands consistent speed and torque.

- Ball Mills: Depend on heavy-duty industrial gearboxes to withstand vibration and overload.

- Roller Presses: Use geared motors for precise torque control, improving grinding efficiency.

Through these applications, gearboxes and geared motors ensure reliability, energy efficiency, and productivity at every stage of cement manufacturing.

Benefits of Industrial Gearboxes in Cement Plants

Energy Efficiency

High-efficiency industrial gearboxes minimise power loss and maximise torque output. By optimising load transfer, they reduce energy consumption and operating costs, a key factor in large-scale cement plants.

Durability and Longevity

Cement environments are harsh with constant exposure to dust, heat, and vibration. Premium gearboxes from Santram Engineers are built with robust housings, precision-cut gears, and superior materials, ensuring long service life.

Cost-Effectiveness

Reliable gearboxes reduce downtime, maintenance expenses, and replacement costs. Over time, investing in a quality gearbox provides excellent ROI through improved operational uptime and energy savings.

Key Considerations for Choosing the Right Gearbox for Cement Plants

Selecting the right gearbox for a cement plant is a technical decision influenced by several factors:

Load and Speed Requirements

Each machine has distinct power needs. For instance, a kiln requires slow, powerful torque, whereas a conveyor system may need moderate speed. Matching gearbox specifications to load and speed ensures performance efficiency.

Environmental Conditions

Cement plants are exposed to dust, heat, and moisture. Choosing corrosion-resistant gearboxes with proper sealing and cooling mechanisms helps maintain longevity.

Mounting and Design Flexibility

Compact and modular gearbox designs ease installation and maintenance. Santram Engineers provides gearboxes in various configurations, foot-mounted, flange-mounted, or shaft-mounted, tailored to your plant’s layout.

Geared Motors in Cement Plant Applications

A geared motor combines an electric motor with a gearbox in a single, compact unit, designed to deliver precise torque and controlled motion. This integration not only enhances mechanical efficiency but also reduces installation space and simplifies maintenance, making it an ideal solution for the demanding, round-the-clock operations of cement plants.

In the cement industry, where heavy materials and continuous loads are part of daily operations, geared motors play an essential role in ensuring uninterrupted productivity. They are widely used in:

- Conveyor Belts for Material Transport: Geared motors drive long conveyor belts that move raw materials such as limestone, clay, and gypsum from one section of the plant to another. They maintain consistent speed, preventing material spillage and ensuring a steady flow of input to crushers and mills.

- Crushers for Breaking Down Raw Materials: Crushers require immense torque to crush large chunks of raw limestone into smaller particles. Geared motors provide the necessary torque multiplication and load control, ensuring smooth operation even under heavy shock loads.

- Rotary Kilns and Cooling Systems: Rotary kilns operate at extremely slow speeds but require high torque and thermal resistance. Specially designed geared motors maintain rotational accuracy and speed uniformity in these high-temperature zones. They also drive clinker coolers and fans that maintain optimal air circulation.

- Packing Units for Finished Cement Bags: In packaging and dispatch sections, geared motors ensure smooth and synchronised operation of conveyor belts, packing machines, and rotary feeders — essential for precise bag filling and consistent output.

Advantages of Geared Motors

Geared motors have become indispensable in modern cement manufacturing due to their performance and efficiency advantages:

- High Efficiency and Torque Density: Integrated gear-motor designs minimise energy loss and deliver maximum torque output, improving the overall power efficiency of plant operations.

- Compact and Integrated Design: Space constraints are typical in cement plants. Geared motors offer a smaller footprint, making them ideal for retrofitting into existing equipment or confined areas.

- Reduced Mechanical Losses: The direct coupling between the motor and gearbox eliminates misalignment and slippage issues, ensuring smooth, vibration-free operation.

- Easy Installation and Alignment: The plug-and-play configuration simplifies setup and reduces downtime during equipment replacement or maintenance.

Key Features of High-Quality Geared Motors

Premium geared motors from Santram Engineers are engineered for heavy-duty cement plant applications and harsh working environments. They deliver:

- Precision Speed Control: Essential for maintaining consistent feed rates in conveyors, crushers, and mills.

- Low Noise and Vibration: Improves workplace safety and reduces mechanical wear over time.

- Minimal Maintenance Requirements: Built with durable components and advanced lubrication systems, ensuring long operational life.

- High Mechanical Efficiency: Enables better energy utilisation, lowering power consumption per tonne of cement produced.

Additionally, Santram Engineers offers customisation options tailored to each plant’s operational needs, whether it’s torque optimisation for kiln drives, compact mounting for packing systems, or special coatings for dust and heat resistance.

By integrating these high-performance geared motors, cement manufacturers can achieve greater reliability, lower energy costs, and higher throughput, ensuring continuous, efficient, and profitable operations.

Maintenance Best Practices for Gearboxes and Motors

Routine Inspections and Preventive Maintenance

Regular inspections help detect wear and tear before it leads to costly downtime. Predictive maintenance using vibration or oil analysis ensures early fault detection.

Lubrication and Cooling Systems

Proper lubrication prevents friction and gear wear. Automated lubrication systems and adequate cooling solutions help maintain temperature control and extend the lifespan of both gearboxes and geared motors.

Training and Documentation

Ensure plant staff receive adequate training on gearbox maintenance and record-keeping. Santram Engineers assists clients with maintenance schedules and technical support for long-term reliability.

Frequently Asked Questions (FAQs)

1. What type of gearbox is best for a cement plant?

Planetary and helical gearboxes are most commonly used due to their high torque, compact design, and energy efficiency. Santram Engineers offers reliable options from Premium Transmission tailored to cement plant applications.

2. How often should gearboxes be serviced in a cement plant?

Regular servicing every 3–6 months is recommended, depending on load and operational hours. Preventive maintenance helps detect early wear and extend gearbox life.

3. What are the benefits of using geared motors in cement plants?

Geared motors save space, improve efficiency, and provide precise speed and torque control — making them ideal for conveyors, kilns, and grinding mills.

4. How do environmental conditions affect gearbox performance?

Dust, humidity, and heat can impact performance and lubrication. Choosing corrosion-resistant gearboxes with robust sealing ensures reliability.

5. Does Santram Engineers offer customised gearboxes for cement applications?

Yes, SEPL provides customised solutions for specific torque, mounting, and environmental requirements, ensuring optimal performance in any cement plant setup.

Conclusion

From conveying limestone to grinding the final product, gearboxes and geared motors drive the core operations of every cement plant. Selecting reliable and efficient transmission systems directly impacts productivity, energy savings, and long-term profitability.

Boost Your Cement Plant’s Performance with Santram Engineers

Your cement plant deserves power transmission systems that are as strong and reliable as your operations. At Santram Engineers, we deliver premium-grade industrial gearboxes and geared motors designed to withstand extreme conditions and optimise efficiency.

As authorised partners of Premium Transmission, Bharat Bijlee, and Emco Dynatorq, our products are trusted by leading cement manufacturers across India. From application engineering to post-sales service, we ensure seamless integration of power transmission solutions that drive performance and reliability.

Upgrade your cement plant with advanced gearboxes and motors from Santram Engineers.

Locations served: Gujarat, Maharashtra, Karnataka, Andhra Pradesh, Telangana, and Chhattisgarh.

Visit Santram Engineers to explore our full range of industrial solutions today.