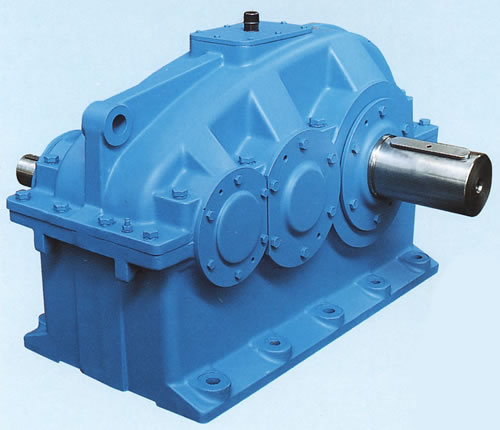

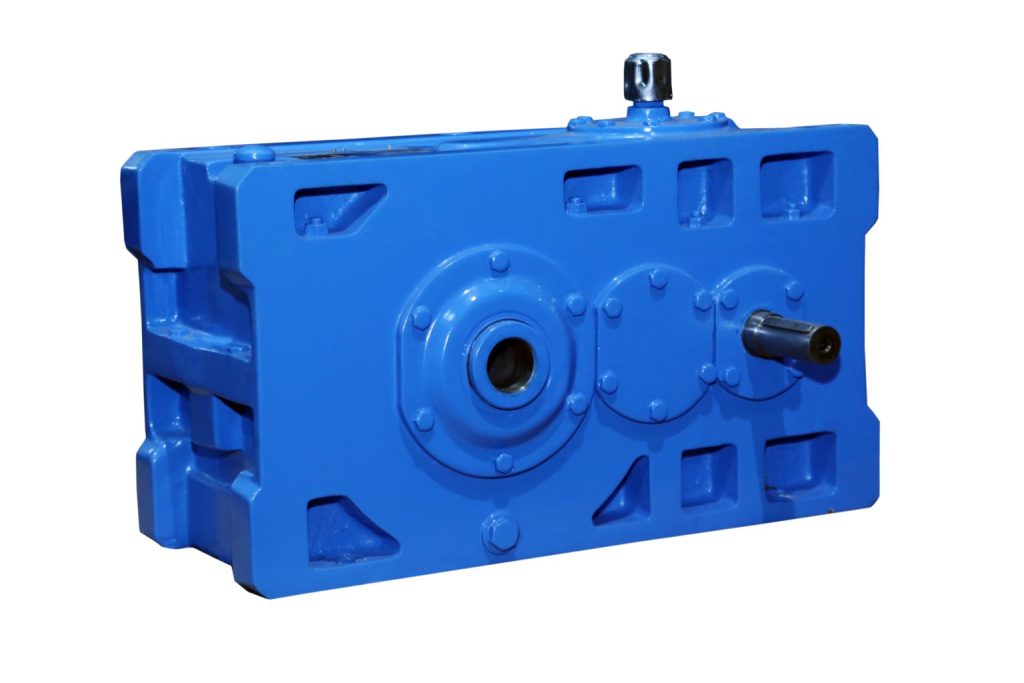

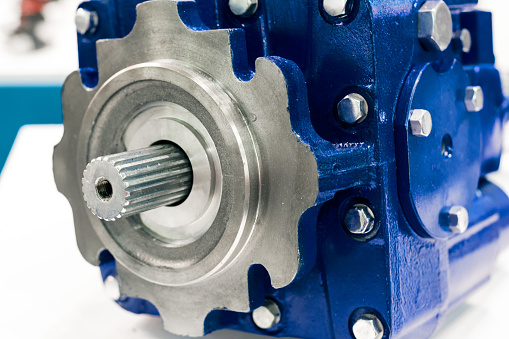

Helical Gearboxes are the most popular gearboxes used in small-scale and large-scale industries. In a helical gearbox, you will find teeth that are oriented at an angle to the shaft. This design allows more than one tooth to be in contact during operations. As a result, the movement is faster and the gearbox is capable of handling more load.

The superior load capacity has caused the wide-scale application of gearboxes across industries. Helical gearboxes are used in the textile, plastic and food industries. Furthermore, there is an integral component of conveyor belts, elevators, blowers, compressors, cutters, etc.

The load-sharing capacity between the teeth of the Helical Gearbox has also resulted in its usage in heavy work sectors such as earth-moving, fertilizers and printing industries.

Types of Helical Gearboxes and Their Applications

There are different types of helical gearboxes – single helical gear, double helical gear and herringbone gear. Santram Engineers offer a host of helical gearboxes of different configurations such as Helical H1 125 3.05:1; Helical H1 125 3.38:1 Parallel Helical Gearboxes, etc.

Single Helical Gearboxes

In single helical gearboxes, the teeth are designed at a certain angle from the axis. As a result, the orientation can either be left or right of the gear. This increases the load capacity of the gearbox and hence this gearbox has found utility in high-load applications.

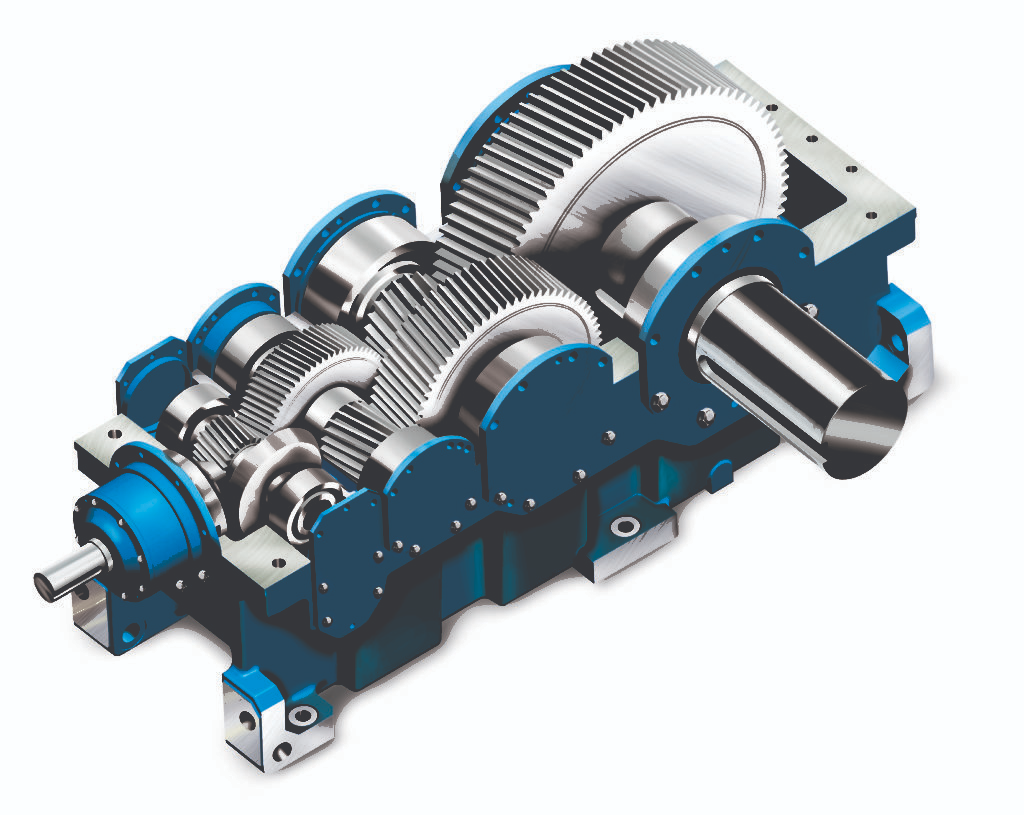

Double Helical Gearboxes

In a double-helical gearbox, two helical surfaces are placed against each other. Each surface has similar and opposite helix angles, separated by a gap, which results in greater engagement between the teeth and smoother movement.

Herringbone Gear

The herringbone gear is similar to the double-helical gearbox, but there is no gap separating the two surfaces. They are smaller in size and are used for high-shock and vibration applications. However, they are not so widely used because they are difficult to manufacture and highly expensive.

Benefits and Applications of Helical Gearboxes

The unique design of the helical gearboxes makes it highly beneficial for industrial applications. The reason for this is that the angled teeth engage more smoothly and function more efficiently. Helical gearboxes are highly durable and hence they find application in high-load works. They also can transmit motion and power between parallel or right-angle shafts.

Helical gearboxes are also used low power applications such as conveyors, mixers, cranes, coolers, extruders and crushers.

FAQs

1. What is a helical gearbox and how does it work?

A helical gearbox is a mechanical device that uses helical gears to transmit power and motion between shafts. The gears in a helical gearbox are cut at an angle (helix angle), allowing them to engage gradually and more smoothly than spur gears. This results in quieter operation, higher load-carrying capacity, and improved efficiency. Helical gearboxes are commonly used in heavy-duty applications such as conveyors, crushers, and mixers where precision and performance are essential.

2. What are the main advantages of using a helical gearbox?

Helical gearboxes offer several benefits over other types of gearboxes. Their key advantages include smooth and quiet operation due to gradual gear engagement, higher torque transmission, and superior load distribution. Additionally, helical gearboxes are known for their high efficiency and durability, making them ideal for both industrial and automotive applications. Their design reduces vibration and noise, which also enhances the lifespan of the connected machinery.

3. What are the different types of helical gear?

There are several types of helical gears used in helical gearboxes, each designed for specific purposes. The main types include:

- Single helical gears – Feature teeth angled in one direction and are simple in design.

- Double helical gears (Herringbone gears) – Have two sets of helical teeth placed in a V-formation to eliminate axial thrust.

- Crossed helical gears – Used when the shafts are non-parallel and non-intersecting.

The choice of helical gear type depends on the application’s torque, speed, and space requirements.

4. How does helical gearbox design differ from other gearboxes?

The design of a helical gearbox is distinguished by its angled gear teeth, which are set at a specific helix angle (typically between 15° and 30°). This design allows for more contact between the gear teeth over a longer duration, which distributes the load more evenly and reduces wear. Compared to spur or bevel gearboxes, helical gearboxes are more efficient, quieter, and capable of handling higher torque loads. Their modular construction also allows easy customization and integration in various machines.

5. Where are helical gearboxes commonly used?

Helical gearboxes are widely used across multiple industries due to their robustness and efficiency. Common applications include material handling systems, conveyors, elevators, mixers, crushers, and packaging machinery. In the automotive sector, helical gearboxes are used in transmissions to ensure smooth and noise-free gear shifting. Their ability to operate under high load and speed conditions makes them a preferred choice for both industrial and commercial environments.

6. How do I select the right helical gearbox for my application?

Selecting the right helical gearbox involves evaluating several key parameters such as torque requirements, speed ratio, input/output shaft orientation, mounting position, and operating environment. You should also consider the gearbox’s thermal capacity, efficiency, and compatibility with your machine. Consulting with a reliable gearbox manufacturer or engineer can help you choose a gearbox that meets your specific performance and budget needs while ensuring long-term reliability.

7. What maintenance does a helical gearbox require?

Proper maintenance of a helical gearbox is essential to ensure long service life and optimal performance. Regular tasks include checking and topping up lubricant levels, inspecting seals and gaskets for leaks, monitoring for unusual noise or vibrations, and conducting periodic wear analysis of gears and bearings. Using the recommended type of lubricating oil and following the manufacturer’s maintenance schedule can significantly reduce downtime and prevent costly repairs.

8. Are there any disadvantages of using a helical gearbox?

While helical gearboxes offer many advantages, they also have some limitations. Due to the angled teeth, they produce axial thrust which requires the use of thrust bearings to counteract the force. They also tend to be more complex and expensive to manufacture compared to spur gearboxes. However, their enhanced efficiency, quiet operation, and load capacity usually outweigh these drawbacks, especially in demanding applications.

9. How does a helical gearbox compare with a spur gearbox?

The primary difference between a helical gearbox and a spur gearbox lies in the design of their gear teeth. Spur gears have straight teeth and engage abruptly, leading to higher noise and stress levels. In contrast, helical gears engage gradually due to their angled teeth, resulting in smoother and quieter operation. Helical gearboxes are also capable of transmitting more torque and handling higher loads, making them better suited for heavy-duty applications where performance and noise reduction are critical.

If you are looking for the right helical gearbox, you can get in touch with Santram Engineers – the leading supplier of power-transmission products.

Reach Out for High-Quality Power Transmission Products

Santram Engineers have decades of experience in helical gearboxes and Power Transmission Products.

The company is the largest distributor and stockiest for Premium Transmission Limited. For any queries related to gearboxes and power transmission products, you can reach out to our experts for consultation by calling us at +91-96247 39393 or writing to us at sales@santramengineers.com. We would be happy to help!