In the complex and high-demand world of industrial machinery, precision and reliability are non-negotiable. Whether it’s automation, manufacturing, material handling, or heavy-duty conveyors, the right industrial gearbox can be the difference between streamlined efficiency and operational headaches.

Among the most trusted and widely used types is the worm gearbox—a compact, robust, and highly effective gear system known for its high torque output and smooth performance. If your business relies on gear-driven equipment, understanding how a worm gearbox works can help you make better buying decisions, ensure optimal performance, and prevent costly breakdowns.

As a trusted dealer of industry-leading brands such as Premium Transmission Private Limited, we’re here to simplify the technical stuff and help industrial buyers make informed decisions. Let’s discuss this article, part by part.

What Is a Worm Gearbox?

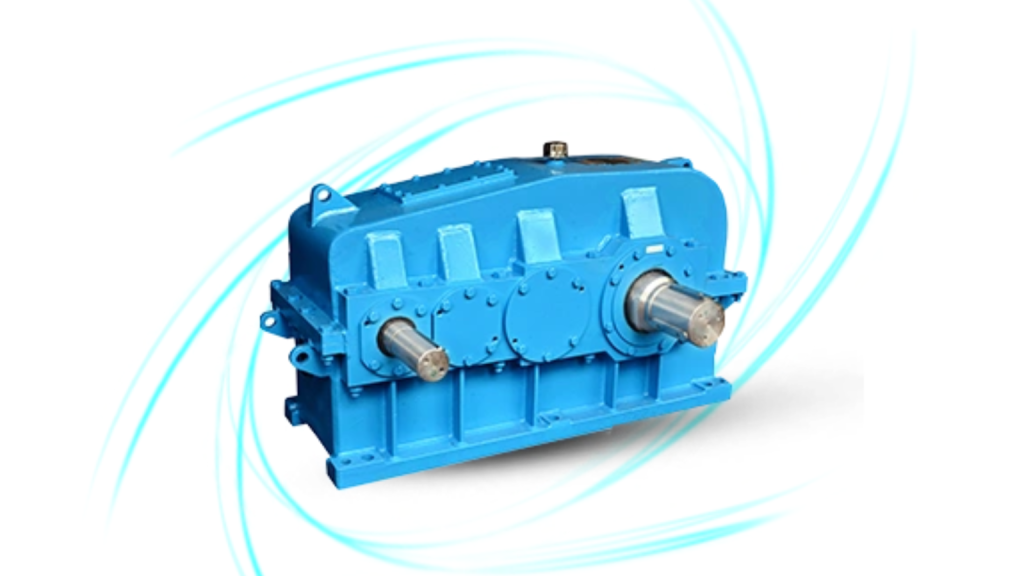

A worm gearbox (also known as a worm drive gearbox) is a type of industrial gearbox that consists of a worm (a screw-like shaft) meshing with a worm wheel (a toothed gear). This unique configuration allows for high torque transfer at low speeds, making these gearboxes ideal for applications that demand heavy lifting, precise control, or self-locking capabilities.

What sets the worm gearbox apart is its ability to deliver a high reduction ratio in a compact footprint, offering strength and control in limited space.

Key Components of a Worm Gearbox

Understanding the anatomy of a worm gearbox gives insight into why it’s favoured across industries. Let’s look at the critical internal components and how they work together:

1. Worm Shaft

The worm shaft resembles a screw and is typically made from hardened steel. It’s the driving component connected to the motor. As the shaft rotates, its spiral thread engages with the worm wheel. Its material, surface finish, and helix angle are crucial to performance, wear resistance, and efficiency.

2. Worm Wheel

Also known as the worm gear, this component meshes with the worm shaft to transmit motion. It’s often made of bronze or other wear-resistant materials to reduce friction and enhance durability. The worm wheel is where the rotational energy is transferred, and its tooth profile ensures smooth engagement with the worm.

3. Bearings and Bushings

These components support the shafts and allow smooth rotation while handling radial and axial loads. High-quality bearings reduce vibration, prevent misalignment, and extend the life of the gearbox. Industrial-grade worm gearboxes often include ball bearings and bronze bushings for balanced load management.

4. Housing and Sealing System

The gearbox casing, usually cast iron or aluminum, encloses all internal components and protects them from dust, debris, and moisture. The seals ensure that lubricants stay in and contaminants stay out, playing a vital role in reducing wear and maintaining thermal balance. Well-designed housing also aids in heat dissipation—an important factor in continuous operations.

The Role of Each Component in Performance and Durability

Each part of the worm gearbox contributes to its signature advantages:

- Worm shaft and wheel: Work together to produce high torque and precise control.

- Bearings: Minimise wear and maintain alignment.

- Housing and seals: Provide structural integrity and environmental protection.

Together, they deliver the legendary reliability and longevity that worm gearboxes are known for.

How a Worm Gearbox Works: Step-by-Step Technical Breakdown

At its core, the worm gearbox works by transferring motion through perpendicular axes using a screw-to-gear interface. Here’s how the process unfolds:

1. Motion Transfer

The electric or mechanical motor rotates the worm shaft. This screw-like shaft turns on a horizontal or vertical axis and engages with the worm wheel’s teeth. Because of the angular setup (typically 90°), the rotary motion of the shaft is transferred to the wheel, changing the direction of force.

2. Torque Transmission & Speed Reduction

As the worm shaft drives the worm wheel, it delivers high torque output while significantly reducing the input speed. The gear ratio is determined by the number of teeth on the worm wheel versus the number of threads (starts) on the worm shaft. For example, a 30:1 ratio gearbox will turn the output shaft once for every 30 turns of the input.

This makes worm gearboxes ideal for:

- Heavy-load applications

- Lifting systems

- Precision machinery

3. Non-Reversible Torque Transfer (Self-Locking)

One of the standout features of worm gearboxes is their self-locking capability. Due to its design, a worm gear typically drives the wheel unidirectionally, preventing back-driving This means when the motor is off, the gearbox can hold its position without external braking systems—perfect for hoists, elevators, or inclined conveyors.

4. Efficiency & Heat Generation

Due to the sliding contact between the worm and wheel, worm gearboxes naturally produce more heat compared to spur or helical gear systems. This results in slightly lower efficiency (typically 50–90%) depending on the load and speed. However, when designed properly and used within load ratings, the heat is manageable and predictable.

To counteract thermal buildup:

- Premium models (like those from Premium Transmission Private Limited) use heat-resistant lubricants and improved materials.

- Gearbox housings are often finned for better heat dissipation.

Technical Factors That Influence Worm Gearbox Performance

Whether you’re operating material handling systems, hoists, or automated machinery, the performance of a worm gearbox is determined by more than just brand reputation. Several technical variables influence efficiency, durability, and overall effectiveness. Understanding these helps businesses choose the right industrial gearbox and optimise its use across various applications.

Let’s break down the key performance influencers in worm gear systems and why they matter.

1. Gear Materials Matter More Than You Think

The combination of materials used in worm shaft and worm wheel construction is critical. Typically, the worm shaft is made of hardened steel while the worm wheel is crafted from phosphor bronze or similar alloys.

Why the difference?

- Hardened steel ensures strength, wear resistance, and a longer operational life of the worm shaft.

- Bronze, on the other hand, offers excellent machinability and reduces friction when meshing with steel, which minimises wear and heat generation in the worm wheel.

High-quality gearboxes use carefully selected material pairings to strike the right balance between durability and efficiency.

2. Tooth Geometry & Surface Finish

Tooth shape (also called geometry) directly affects how smoothly and efficiently the worm and wheel engage. In worm gearboxes, the worm typically has a helical thread profile that engages a concave tooth in the wheel. Proper tooth geometry:

- Reduces sliding friction

- Enhances load-bearing capacity

- Improves overall contact ratio and efficiency

Additionally, a finely finished surface on gear teeth reduces micro-wear and lowers the chances of pitting and fatigue—common issues in long-term industrial operations.

3. Backlash & Alignment in Precision Applications

Backlash is the slight play between meshing teeth. While some backlash is necessary for lubrication and thermal expansion, too much can lead to:

- Inaccurate positioning in robotics or automation

- Excessive noise or vibration

- Accelerated wear and tear

Proper shaft alignment during installation and ongoing calibration is essential. Misalignment causes uneven tooth engagement, which not only reduces lifespan but also affects system accuracy and consistency.

Industrial buyers working in automation-heavy sectors should ensure their worm gearbox includes low-backlash options or is compatible with precision tuning systems.

4. Housing Design & Heat Dissipation

Due to the sliding motion between the worm and the wheel, worm gearboxes inherently produce more heat than other gear types. Without proper housing and cooling, this can degrade performance and damage internal components.

Look for gearboxes with:

- Cast iron or aluminium housings for strength and heat transfer

- Finned designs that naturally dissipate heat

- Sealed enclosures to prevent contamination while retaining lubricants

Manufacturers like Premium Transmission Private Limited often incorporate these features in their industrial-grade gearbox lines, ensuring reliable performance even in demanding, continuous-use scenarios.

FAQs

1. What is the ideal speed ratio for a worm gearbox in heavy-duty applications?

Speed ratios from 20:1 to 60:1 are common in heavy-duty applications. The ideal ratio depends on the torque requirement and input speed. Higher ratios offer greater torque multiplication but reduced output speed.

2. How often should worm gearboxes be serviced in continuous operation environments?

For 24/7 applications, routine inspection every 3–6 months is recommended. Lubricant replacement, seal checks, and temperature monitoring are essential. Follow manufacturer guidelines or consult your gearbox dealer for tailored maintenance for your gearbox.

3. What causes noise or vibration in a worm gearbox?

Common culprits include:

- Misalignment of shafts

- Worn or damaged bearings

- Excessive backlash

- Inadequate or degraded lubrication

Early diagnosis and professional servicing can prevent further mechanical damage.

4. Can I use synthetic lubricants in worm gearboxes?

Yes, synthetic lubricants are often recommended for better thermal stability, reduced friction, and longer intervals between oil changes. Always check compatibility with seal materials and follow the gearbox manufacturer’s guidelines.

5. How do I size a worm gearbox for vertical load applications?

When sizing for vertical loads, consider:

- Required torque and reduction ratio

- Load type (static vs dynamic)

- Mounting position and self-locking capability

- Service factor adjustments for continuous or fluctuating loads

Your gearbox dealer can help select a model with the right load-bearing specs and alignment features.

Why Partner with Santram Engineers for Worm Gearbox Solutions?

When performance, reliability, and scale matter, Santram Engineers delivers. As a leading supplier of worm gearboxes and the largest distributor Premium Transmission Private Limited, we offer an extensive range of industrial gearbox variants tailored for every application. From compact models for space-constrained setups to heavy-duty gearboxes for high-torque demands, our inventory supports high-volume requirements and custom-engineered solutions.

Industries across India—textiles, packaging, material handling, and more—count on us for gearbox solutions that perform under pressure. But it’s not just about products. Our strength lies in end-to-end service excellence: from expert installation support to timely replacements and technical guidance.

Looking to upgrade or streamline your gearbox operations? Partner with Santram Engineers—where engineering meets dependability. Contact us at +91 96247 39393 or email us at sales@santramengineers.com for expert consultation and tailored gearbox solutions that drive your business forward.