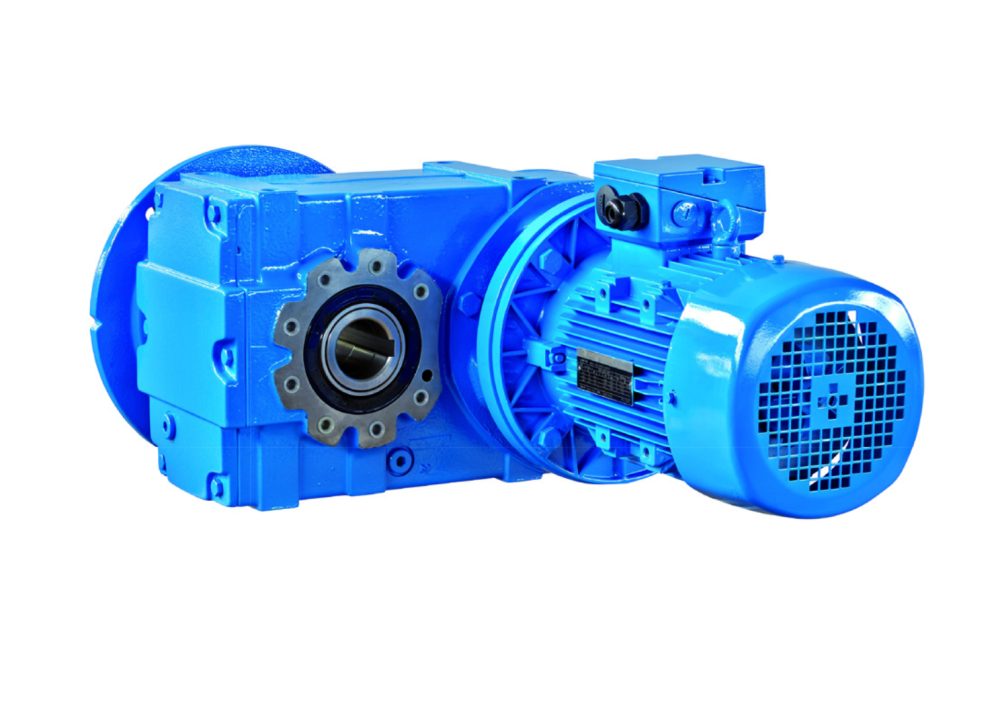

Geared motors are fundamental to many industrial applications, from conveyor systems to automation processes. As these motors age, their performance can degrade, leading to inefficiencies and higher operational costs. The decision to replace a geared motor is not always straightforward, but understanding the signs of decline can save businesses time, money, and effort in the long run.

In this blog, we’ll explore when it’s time to replace your geared motor, the hidden costs of holding onto older models, and the numerous benefits of upgrading to a newer, more energy-efficient motor.

The Hidden Costs of Continuing with Old Geared Motors

Point 1: Growing Inefficiency and Rising Energy Costs

As geared motors age, they lose efficiency. Even with regular maintenance, the components in older motors, such as bearings, gears, and windings, suffer wear and tear. This can cause the motor to operate less efficiently, consuming more energy for the same output. Over time, this inefficiency becomes increasingly noticeable, driving up your energy costs.

For example, older geared motors often operate at only 70–80% of their initial efficiency after several years of use. In a large-scale industrial setting, this drop in efficiency can lead to a substantial increase in energy consumption. Helical geared motors, which are designed for higher torque and smoother operation, can also experience efficiency losses if not replaced in time, resulting in unnecessary energy expenses.

By replacing your outdated motor with a Premium Transmission motor, you can benefit from new technologies that focus on energy efficiency. Modern geared motors are designed to meet stringent energy standards, reducing power consumption and offering a better return on investment. Even though the initial cost of a new geared motor may seem high, the long-term savings in energy costs often far outweigh the upfront expense.

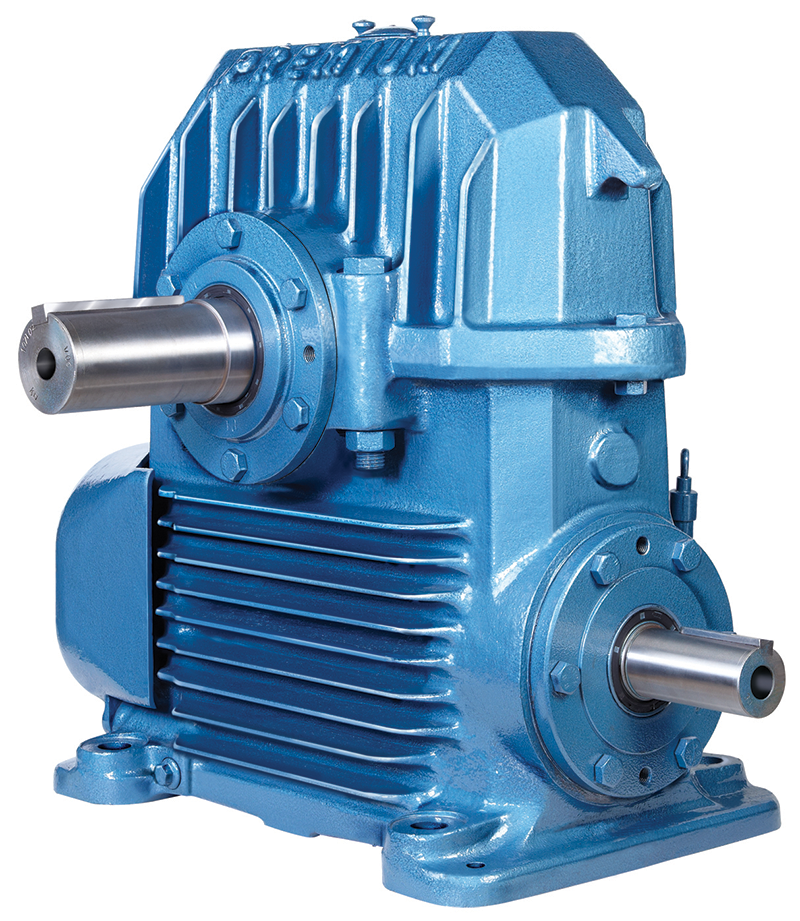

Furthermore, worm geared motors, while great for specific applications, may struggle with energy efficiency as they age due to friction losses in the gear setup. Replacing them with newer models equipped with advanced materials or optimised gear ratios can reduce energy losses and improve the overall system performance.

Point 2: The High Cost of Frequent Repairs

As your geared motor ages, the likelihood of mechanical failures increases. Parts such as bearings, seals, and gears wear out, resulting in frequent repairs. What might start as a minor issue can snowball into more significant problems as the motor’s components continue to degrade. Repair costs can add up quickly, and eventually, the cost of maintaining an ageing motor may exceed the cost of replacing it altogether.

For instance, consider a geared motor that frequently requires bearing replacements or gearbox maintenance. Over the course of a year, the cost of these repairs may amount to thousands of rupees. Meanwhile, if you continue to delay replacing the motor, the risk of a complete failure grows, potentially leading to unexpected downtimes and lost production.

Newer helical or worm geared motors, by contrast, benefit from advances in materials, design, and manufacturing that improve their durability and lifespan. These motors are built to handle high loads with minimal wear and tear, reducing the need for frequent repairs. While there is an upfront cost, the long-term savings, both in terms of reduced downtime and lower maintenance costs, make the investment worthwhile.

When Should You Replace Your Geared Motor?

Performance Decline Beyond Repair

One of the clearest signs that your geared motor needs replacing is when its performance deteriorates to a point where repairs can no longer restore it to full functionality. Some common symptoms to watch out for include:

- Inconsistent Speed: If your motor struggles to maintain a consistent speed, particularly when handling varying loads, this can cause disruptions in your production process. Inconsistent speed can also affect the quality of the end product, leading to customer dissatisfaction.

- Overheating Despite Maintenance: Older motors, especially worm geared motors, may experience overheating issues despite regular maintenance. This happens because internal components become worn, causing friction and heat buildup. Overheating can damage the motor and reduce its lifespan, resulting in unplanned downtime.

- Loss of Torque or Load Handling Capacity: A geared motor that can no longer handle the torque or load it was designed for is a major red flag. If your motor is struggling to lift or move heavy objects, or if it’s unable to maintain the desired torque, the motor’s performance is severely compromised.

These performance issues are signs that the motor has reached the end of its useful life. No matter how many repairs are made, the motor will likely continue to experience performance issues. It’s time to invest in a new geared motor that will restore your system’s reliability and efficiency.

Technological Advances That Make Upgrading Necessary

In addition to performance declines, older motors may lack the advanced features that are now standard in modern geared motors. Technological innovations have made geared motors more efficient, precise, and user-friendly. Features like smart sensors, IoT capabilities, and energy-saving designs are now common in newer models. These features help monitor motor health in real-time, predict failures before they occur, and optimise performance for maximum efficiency.

For example, a modern helical geared motor with built-in smart sensors can send real-time data on the motor’s speed, temperature, and load conditions, allowing operators to detect any irregularities before they fail. Similarly, Premium Transmission motors from Santram Engineers, offer advanced diagnostic features that help reduce downtime by alerting technicians to maintenance needs.

Upgrading to a newer motor can give businesses a competitive edge by improving precision, reducing downtime, and enhancing operational efficiency. These features allow for better control over the production process and ensure that the system operates at peak performance, reducing the likelihood of unexpected failures.

How to Assess When to Upgrade

Key Indicators That It’s Time for an Upgrade

If you’re unsure when to replace your geared motor, here are several key indicators that it’s time for an upgrade:

- Excessive Unplanned Downtime: Frequent breakdowns, even after repairs, indicate that the motor is nearing the end of its lifespan. Unplanned downtime can lead to significant losses in productivity, affecting both your bottom line and customer satisfaction.

- Inability to Meet Performance Demands: As production speeds increase or load requirements change, an older motor may struggle to keep up. If your motor can no longer meet the required torque or speed, it will hinder your system’s ability to perform as expected, causing delays and reducing output.

- Rising Operational Costs: If the motor is consuming more energy than it did when it was new, or if repair costs are rising, it’s time to consider an upgrade. A geared motor that requires constant maintenance and higher energy consumption may be costing you more than it’s worth.

Evaluating the Economic Benefits of Replacing

Performing a cost-benefit analysis is an effective way to determine whether it’s more economical to continue repairing your old motor or to replace it entirely. For instance, let’s assume that an old motor costs ₹50,000 in repairs and energy consumption annually. If a new geared motor costs ₹120,000 but reduces energy consumption by 30% and cuts repair costs by 50%, the long-term savings are substantial.

New motors can pay for themselves over time through lower energy bills, fewer repairs, and increased system uptime. In this case, the initial investment in a new motor would pay off in just a few years, leading to long-term savings and improved operational efficiency.

The Benefits of Replacing Your Geared Motor

Energy Efficiency and Environmental Impact

Upgrading to a new geared motor can significantly reduce energy consumption. Modern motors are designed with energy efficiency in mind, often meeting or exceeding the latest industry standards. By switching to a more energy-efficient motor, you’ll reduce your overall energy costs and decrease your carbon footprint.

For example, Premium Transmission geared motors are known for their energy-efficient designs, which reduce energy consumption significantly. This not only leads to cost savings but also supports your company’s sustainability goals. Additionally, businesses that prioritise energy efficiency often enjoy better regulatory compliance and may be eligible for energy-saving incentives or tax breaks.

Enhanced Performance and Reliability

New geared motors offer enhanced performance and reliability. For instance, helical geared motors are known for their smooth operation and high torque output, making them ideal for demanding industrial applications. A new motor will provide more consistent and reliable performance, reducing the likelihood of unexpected breakdowns or unplanned downtime.

The increased reliability of modern motors helps maintain consistent production, which is critical for meeting production goals and minimising disruptions. With advanced diagnostics and monitoring systems, these motors are also easier to maintain and less prone to failure.

Longer Motor Lifespan

One of the key advantages of replacing your old geared motor is that new motors typically last much longer. While an ageing motor may need to be replaced every 3–5 years, a new motor, if properly maintained, can last 10 years or more. This extended lifespan results in fewer replacements and a better return on investment over time.

Key Considerations When Replacing Your Geared Motor

Identifying the Right Motor for Your System

When selecting a new geared motor, it’s important to match the motor’s specifications with the needs of your system. Consider the following factors:

- Torque and Speed Requirements: The motor should provide sufficient torque to handle the load and maintain the desired speed.

- Gear Ratio: Ensure the motor’s gear ratio is suitable for your application, whether it’s for high-speed operations or heavy-duty tasks.

- Mounting Configuration: Verify that the motor fits into your existing system setup and meets any mounting requirements.

Selecting the right motor will ensure optimal performance and minimise the risk of future problems.

AC vs. DC Motors: Making the Right Choice

Deciding between AC and DC geared motors depends on the specific demands of your application. AC motors are ideal for high-power, heavy-duty applications and are often more durable. DC motors, on the other hand, are known for their precise speed control and energy efficiency, making them suitable for applications that require fine control.

Advanced Features to Look for in New Geared Motors

When upgrading your geared motor, look for modern features that can enhance the performance and longevity of the motor. Some features to consider include:

- Smart Sensors for monitoring performance in real-time

- IoT Connectivity for predictive maintenance and remote diagnostics

- Built-in Diagnostics to alert you to any potential issues before they result in downtime

These features can provide real-time insights into the motor’s health and prevent issues from escalating into costly repairs.

The Replacement Process – What You Need to Know

How to Prepare for Geared Motor Replacement

Before replacing your motor, ensure that you:

- Measure the motor specifications to confirm compatibility with your system.

- Check for any system changes that may require adjustments to the new motor.

- Plan for installation, ensuring that proper alignment and balancing are achieved.

When to Call in a Professional

If the motor replacement requires complex adjustments or if you’re unsure about the installation process, it’s advisable to call in a professional. A technician can ensure that the new motor is installed correctly and that your system runs optimally after the upgrade.

Conclusion

Upgrading your geared motor, whether it’s a helical or worm geared motor, or any other type, can bring significant benefits to your system. From improved energy efficiency to enhanced performance and reliability, the advantages of replacing old motors far outweigh the costs of repairs and energy waste. By understanding the signs that it’s time to upgrade and evaluating the economic benefits, you can make an informed decision that optimises your system’s efficiency, reduces downtime, and saves money in the long run.

Ask Experts When It’s Time to Replace Your Geared Motor for Better Efficiency and Performance!

Is your geared motor struggling to keep up with your system’s demands? Don’t let inefficiencies and frequent breakdowns affect your productivity. At Santram Engineers, the largest distributor of Premium Transmission, a leading manufacturer of geared motors, we’re here to help you assess whether it’s time for an upgrade. With years of experience in geared motors, we’ll guide you in choosing the perfect motor that fits your needs.

By upgrading to a new, high-performance motor, you’ll enjoy improved efficiency, reduced energy costs, and fewer maintenance issues. Whether you need a precise torque solution or an energy-efficient design, we’ll help you make the right choice for long-term success.

Contact us at +91 96247 39393 or email us at sales@santramengineers.com for personalised advice and ensure your system stays at peak performance. Let’s work together to make your business more efficient and reliable.

Also Read: What Are Geared Motors?