Imagine you have just purchased a powerful standard AC motor for a new conveyor line at your factory. You check the nameplate and see the standard rating of 1440 RPM. However, your conveyor belt needs to move much slower to carry materials safely. It needs to turn at a steady 50 RPM. If you connect that high-speed motor directly to the conveyor roller, the system will fail instantly or run dangerously fast.

You need a device to bridge this massive gap. You need a component that can take high speed and convert it into usable, controlled power. This is the primary job of a helical gearbox.

At Santram Engineers, we guide hundreds of plant managers and procurement officers through this exact selection process every month. A common point of confusion arises when we ask about stages. Many customers assume we are asking about the type of gear teeth or the mounting position.

This guide clarifies exactly what gearbox stages are and why they matter. We will look at why matching the motor speed to your application speed is the most critical step in gearbox selection. We will also explain the difference between single, double, and triple-stage reduction so you can make the best purchase for your facility.

Note that in this article, “stages” refers strictly to the number of gear sets inside the box. It does not refer to the geometry of the gear teeth themselves.

What Are Gearbox Stages and How Reduction Works

The concept of a stage is fundamental to understanding how a helical gearbox functions. In the simplest terms, a stage represents one point where speed is reduced and torque is increased.

Think of it as a relay race for power. The power enters the gearbox from the motor. It has to pass through a set of gears to get to the output shaft.

- 1 Stage equals one pair of gears meshing together.

- 2 Stages equals two pairs of gears.

- 3 Stages equals three pairs of gears.

The Mechanics of Reduction

When a small gear (the pinion) drives a larger gear, the speed drops. If the small gear has 10 teeth and the large gear has 50 teeth, the ratio is 5:1. The large gear turns five times slower than the small one. This is a single stage of reduction.

If you need to slow the motor down even more, you add another set of gears. The output of the first set becomes the input for the second set. This is a multi-stage reduction.

The Trade-off Between Torque and Efficiency

As you add more stages to a helical gearbox, two things happen simultaneously. First, the torque output increases significantly. This is great for heavy lifting. Second, the efficiency drops slightly. Every time gears mesh, there is friction. Friction creates heat and results in a tiny loss of power.

A single-stage unit might be 98% efficient. A triple-stage unit might drop to 94% or 95%. This is a small price to pay when you need massive power to turn a rock crusher or a heavy mixer. Understanding this trade-off is the first step in selecting the right unit for your specific industrial application.

Single Stage Helical Gearboxes for High Speed Needs

A single-stage helical gearbox is a precision instrument designed for speed. It is the sprinter of the gearbox world. These units contain only one pair of gears—a pinion and a gear wheel. Because there is only one mesh point, there is very little internal friction.

Where You Will See Them Used

We typically recommend single-stage units for applications that require high output speeds. If your motor runs at 1440 RPM and you need the machine to run at 300 RPM or 400 RPM, a single stage is perfect.

Common applications include:

- Centrifugal pumps where high impeller speed is needed to move fluids.

- Industrial fans and blowers that require high rotational velocity for air movement.

- Compressors in manufacturing plants.

- Textile machinery, where specific high-speed rollers are used.

The reduction ratios for these boxes are usually small. They typically range from 1.2:1 up to about 6:1. If you need to slow the motor down more than that, a single stage is physically limited. The gear wheel would have to be too large to fit in the casing.

The Efficiency Advantage

The biggest selling point of a single-stage helical gearbox is efficiency. Since the power only passes through one contact point, very little energy is lost as heat. These units often run cooler than multi-stage boxes. For a factory manager, this means lower electricity bills over time. It also means less thermal stress on the lubricant inside the box.

At Santram Engineers, we stock high-quality single-stage units that are compact and robust. They are ideal for inline drives where the motor and the driven machine are aligned.

Double Stage Helical Gearboxes as the Industry Standard

The double-stage (or 2-stage) gearbox is the most versatile unit we supply. It is the workhorse of the manufacturing sector. If you walk into any automotive plant, food processing facility, or cement factory, you will likely see 2-stage helical gearbox units driving the machinery.

How It Works

In a double-stage unit, the reduction happens twice.

- The input shaft (connected to the motor) drives a gear set to step down the speed.

- That intermediate shaft drives a second gear set to step down the speed again.

- The final power is delivered to the output shaft.

This “double step” allows engineers to achieve much higher reduction ratios without making the gearbox huge. A double-stage box can handle ratios from approximately 8:1 all the way up to 40:1 or sometimes 50:1.

Why It Is the Most Common Choice

Most industrial applications do not need the high speed of a fan (single stage) or the ultra-slow speed of a kiln (triple stage). They fall in the middle.

Think about a standard belt conveyor carrying boxes in a warehouse. A motor speed of 1440 RPM is too fast. But 300 RPM is still too fast. You likely need the conveyor pulley to turn at roughly 60 to 100 RPM. A 2-stage helical gearbox hits this sweet spot perfectly.

Best Applications Include:

- Belt conveyors for material handling.

- Liquid agitators in chemical tanks.

- Packaging machinery requiring precise movement.

- Screw feeders for light materials like grain or plastic pellets.

- Rotary airlocks in dust collection systems.

The 2-stage unit offers the best balance of cost and performance. It provides excellent torque multiplication. It is compact enough to fit in tight spaces. It is also highly reliable for continuous duty cycles.

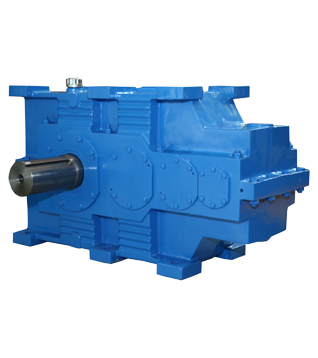

Triple and Quadruple Stages for Mastering High Torque

Sometimes, you need to move mountains. When the load is incredibly heavy or the required speed is extremely slow, a 2-stage box is not enough. You must calculate the torque even further. This is where triple (3-stage) and quadruple (4-stage) gearboxes come into play.

When to Use Multiple Stages

These units are designed for high-torque, low-speed applications. If you need a reduction ratio of 50:1, 100:1, or even higher, you must use three or more stages.

Trying to achieve a 100:1 ratio with fewer stages would require gears that are impractically large. By using three smaller reduction steps, manufacturers can keep the helical gearbox compact while delivering massive power.

Best Applications Include:

- Heavy-duty lifting, such as cranes and hoists.

- Slow-moving mixers for thick, viscous materials like asphalt or dough.

- Crushers and shredders in recycling and mining.

- Water treatment aerators that turn slowly in large tanks.

- Bucket elevators lifting heavy raw materials vertically.

The Trade-off Discussion

The main trade-off here is efficiency. As we mentioned earlier, every gear mesh creates friction. A 3-stage helical gearbox has three mesh points. A 4-stage has four. This means the efficiency might drop to around 94% or 93%.

However, efficiency is not the only metric. In these applications, torque is king. You are willing to sacrifice a tiny percentage of electrical efficiency to ensure the machine has enough twisting force to crush rock or lift steel beams.

Additionally, because these units turn so slowly, they generate internal heat differently. Proper lubrication becomes critical. At Santram Engineers, we always advise our clients on the correct oil viscosity for multi-stage units to ensure long gear life.

How to Calculate the Ratio You Need

You do not need to be a mathematician to select the right helical gearbox. The selection process starts with a simple formula. You must determine the “Reduction Ratio” (often written as ‘i’).

The Simple Formula:

Ratio (i) = Input Motor RPM ÷ Desired Output RPM

You need two numbers:

- Motor Speed: This is written on your electric motor’s nameplate (e.g., 1440 RPM, 960 RPM, or 2800 RPM).

- Output Speed: This is the speed your machine needs to run at (e.g., 50 RPM).

A Real-World Calculation Example

Let’s say you are setting up a screw conveyor. You have a standard 4-pole motor that runs at 1440 RPM. Your process engineer tells you the screw needs to turn at 30 RPM to move the material at the correct rate.

Ratio = 1440 ÷ 30 = 48

You need a reduction ratio of 48:1.

Interpreting the Result

Now, look at the ranges we discussed:

- Single Stage: Up to 6:1 (Too low)

- Double Stage: Up to ~40:1 (Too low)

- Triple Stage: 50:1 and above (Perfect fit)

In this case, a ratio of 48 is right on the border. A 2-stage box might be available at that ratio from some brands, but it would be pushing the limits of the gear teeth. A 3-stage helical gearbox would handle this ratio comfortably. It would provide higher torque safety factors and run smoother.

At Santram Engineers, we often suggest going with the 3-stage option in these borderline cases. It ensures the internal gears are not overstressed. It provides a better service life for your investment.

Why Service Factor Matters in Stage Selection

While the ratio is the first number you calculate, you cannot ignore the “Service Factor.” This is a safety margin. It accounts for how hard your machine works.

A fan that runs for one hour a day is an easy load. A rock crusher that runs 24 hours a day with heavy shock loads is a hard load.

If you select a helical gearbox based only on ratio, you might fail to account for shock loads. A 2-stage box might theoretically provide the speed you need. But if the application has heavy vibrations or frequent starts and stops, the gears might fail.

Often, moving up to a 3-stage box or a larger frame size provides the extra strength needed for high service factors. When you consult with our team, we ask about your daily operating hours and the type of load. This helps us recommend a gearbox that won’t just fit, but will last for years.

The Role of Mounting and Space

Another factor that influences stage selection is physical space. A single-stage helical gearbox is usually longer but narrower. A multi-stage box might be shorter in length but wider due to the arrangement of gears.

Sometimes, a factory has limited space. You might need a bevel-helical unit (which turns 90 degrees) instead of a straight inline helical unit. However, the principle of stages remains the same. More stages equal more torque and a slower speed.

Santram Engineers stocks various mounting options. Our inventory includes robust foot-mounted configurations designed for secure installation on a structural base. We have flange-mounted units that bolt directly to the machine. We can help you navigate these physical constraints once the correct stage and ratio are determined.

Conclusion

Selecting the right gearbox is about more than just buying a part. It is about ensuring the reliability of your entire production line. The difference between a single, double, or triple-stage unit defines how your machine performs.

- Choose the single stage for high-speed pumps and fans where efficiency is the priority.

- Choose the double stage for the vast majority of standard conveyors and processing machinery.

- Choose the triple stage when you need to slow things down significantly and generate massive torque for heavy loads.

Always start by calculating your ratio. Use the formula: Motor RPM divided by Output RPM. Once you have that number, you can see which category your application falls into.

Frequently Asked Questions

1. How do I choose between a 2-stage and 3 stage helical gearbox?

Start by calculating your required reduction ratio. If the ratio is below 40:1, a 2-stage helical gearbox is usually the most cost-effective choice. If your required ratio is above 50:1, or if you need very high torque for a heavy application, a 3-stage unit is better. If you are on the borderline (like 45:1), ask our experts. We often recommend the 3-stage unit for better durability.

2. Does adding more stages reduce the efficiency of my helical gearbox?

Yes, it does reduce efficiency slightly. A single-stage box is about 98% to 99% efficient. A 2-stage box is roughly 96% to 97% efficient. A 3-stage box is about 94% to 95% efficient. This is because every extra gear mesh creates a small amount of friction. However, this small loss is necessary to gain the high torque needed for slow-speed applications.

3. Which helical gearbox stage is best for low speed and high torque?

A triple (3-stage) or even quadruple (4-stage) gearbox is the best choice for low speed and high torque. These units step down the speed multiple times inside the casing. This multiplies the torque at the output shaft significantly. They are essential for heavy machinery like mixers, crushers, and heavy-duty hoists.

4. What are the main benefits of using a single-stage helical gearbox?

The main benefits are high efficiency and a compact, inline design. Because there is only one gear set, there is very little power loss. They are excellent for high-speed applications like pumps and fans, where you do not need a massive increase in torque.

Contact Santram Engineers to Choose the Right Gearbox for Your Application

Selecting the precise helical gearbox configuration for your facility is a critical decision that directly impacts production efficiency and long-term operational costs. You do not have to navigate complex reduction ratio calculations or service factor adjustments alone. At Santram Engineers, our dedicated technical experts are ready to analyze your specific motor speed and torque requirements to recommend the absolute best solution.

Whether you require a standard replacement unit or a fully customized drive system design for heavy-duty machinery, we ensure you receive premium quality, expert advice, and maximum durability. Partner with us to optimize your industrial performance today.

Get in Touch for Expert Assistance:

📞 Phone: +91 96247 39393

📧 Email: sales@santramengineers.com