Power transmission gearboxes are often considered the unsung heroes of mechanical systems, playing a pivotal role in ensuring efficient power transfer across various industrial applications. From heavy machinery in manufacturing plants to wind turbines generating clean energy, these industrial gearboxes facilitate the conversion and transmission of mechanical power while maintaining precision and efficiency. Understanding the components, types, applications, and maintenance of power transmission gearboxes is crucial for industries looking to optimise their operations, reduce downtime, and increase the lifespan of their equipment.

In this guide, we’ll explore everything you need to know about power transmission gearboxes—what makes them unique, how they work, the different types available, and how to choose the right one for your specific needs. We will also take a look at premium gearboxes, their advantages, and why working with reliable premium gearbox dealers in Hyderabad, Rajasthan, Kerala, Odisha, and Delhi is essential for ensuring your systems operate at peak performance.

What Are Power Transmission Gearboxes?

Power transmission gearboxes are mechanical devices designed to transmit rotational power from a motor or engine to various machinery components, typically adjusting the speed, torque, and direction of that power in the process. Gearboxes are integral in ensuring that the energy produced by the power source is delivered efficiently to the system, whether that’s in an industrial machine, an electric vehicle, or even a wind turbine.

In industries such as automotive, manufacturing, and renewable energy, the role of a power transmission gearbox cannot be overstated. These gearboxes allow systems to operate at the desired speed, manage torque efficiently, and maintain consistent power transfer over extended periods of use. Choosing the right industrial gearbox or premium gearbox is crucial to reducing energy waste and preventing operational failures that could lead to costly downtime.

What Makes Power Transmission Gearboxes Unique?

Power transmission gearboxes differ from other gearboxes because they are specifically designed to handle significant torque and high power levels. These gearboxes are optimised to transmit power across mechanical systems at various speed ratios, with some designs facilitating direction changes as well. While a basic gearbox may only focus on small adjustments in speed or torque, a power transmission gearbox is capable of managing larger, more complex adjustments, especially in high-demand environments.

The core function of these gearboxes is to adapt the mechanical power output from a motor or engine, making it suitable for the specific needs of machinery. Power transmission gearboxes are engineered to manage the transmission of energy with minimal loss and optimal efficiency, which is why they are commonly used in industrial settings.

Core Components of Power Transmission Gearboxes

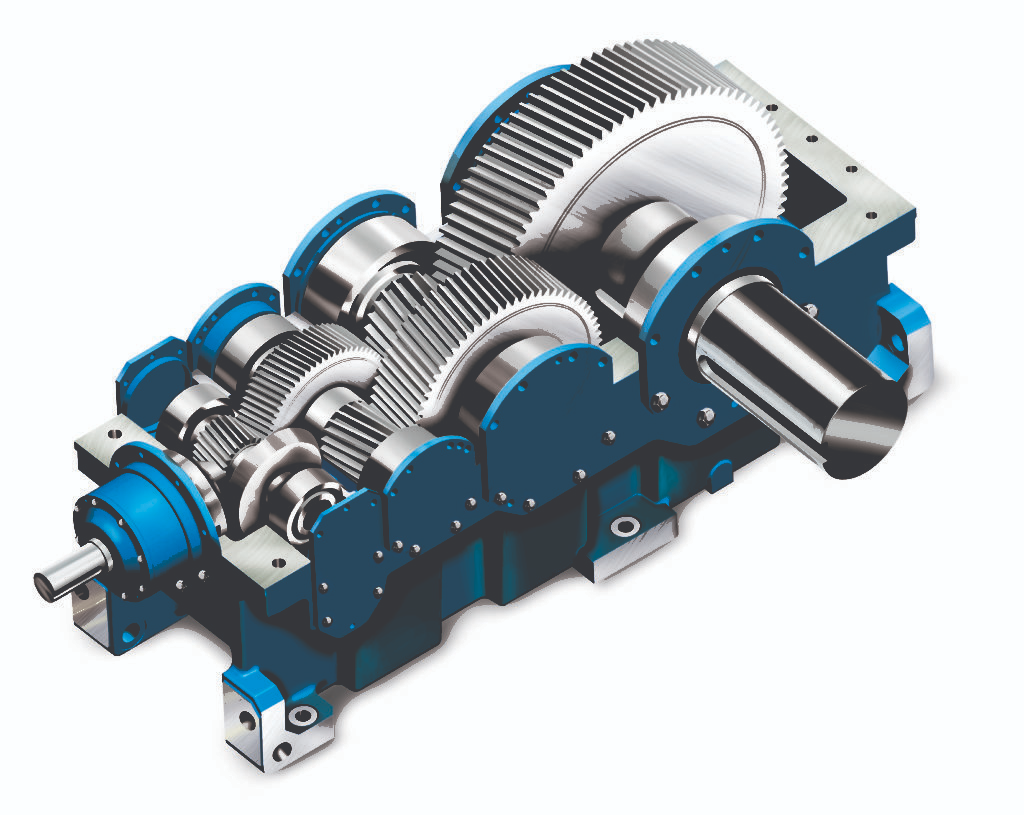

The components that make up power transmission gearboxes are designed to handle high levels of torque and rotational energy, ensuring smooth operation in demanding environments. These components include:

- Gears: The central element of the gearbox, gears mesh with one another to transfer power from one shaft to another. Various types of gears are used in power transmission gearboxes, such as helical, bevel, and planetary gears, each offering unique benefits depending on the application.

- Shafts: These are used to transfer the rotational energy generated by the power source to the output, passing through the gearbox assembly.

- Bearings: Bearings reduce friction between moving parts and help support rotating shafts, contributing to smoother, quieter operation.

- Housing: The gearbox casing protects the internal components from external elements and environmental conditions, ensuring durability and longevity.

Precision engineering plays a crucial role in ensuring that each of these components works together efficiently, resulting in optimal performance for the system in which the gearbox is used.

How is the Power Transmission Gearbox Structured?

At its core, a typical power transmission gearbox consists of gears, shafts, bearings, and a housing. These components are arranged in a manner that allows power to be transferred from the input side (usually from a motor) to the output side (used to drive machinery or other components). In simple designs, the gearbox may feature a straight or helical gear connected by two parallel shafts.

A simple gearbox setup typically features an input shaft that meshes with a gear that then transfers power to an output shaft. This basic structure is commonly used in smaller, low-torque applications.

Complex Gearbox Structures

More advanced systems, such as the coaxial planetary gearbox, are designed to handle higher power requirements. These systems feature sun, planet, and ring gears arranged along with a carrier. The coaxial planetary design helps distribute the load more efficiently, providing greater torque while maintaining a compact footprint. This makes it ideal for applications where both space and high torque are essential, such as in aerospace or high-performance automotive engines.

Key Features of Power Transmission Gearboxes

High Torque Capacity

One of the standout features of industrial gearboxes is their high torque capacity. In industries such as mining, steel manufacturing, and construction, gearboxes must manage extremely high power loads. These gearboxes are engineered to handle the torque demands of heavy-duty applications, ensuring machinery operates smoothly even under immense pressure.

Efficiency

Gearbox efficiency is a critical factor in ensuring the effective transfer of energy. High-quality premium gearboxes are designed to reduce power losses, ensuring that the maximum amount of energy generated by the motor is transmitted to the output system. Modern power transmission gearboxes are built to achieve up to 95% efficiency or more, drastically reducing energy consumption and improving overall system performance.

Compact Design

Modern power transmission gearboxes are designed with space efficiency in mind. In many industrial settings, machinery and equipment operate in tight spaces, requiring compact gearbox solutions. The ability to deliver high power in a smaller form factor makes these gearboxes ideal for applications in crowded environments, such as automotive engines or industrial robots.

Customization Options

Not all power transmission systems are created equal, which is why premium gearboxes offer a wide range of customisation options. Depending on the application, gearboxes can be tailored to meet specific requirements in terms of output speed, torque, mounting configuration, and other factors. This flexibility ensures that the gearbox can fit perfectly into the existing system, optimising performance and minimising energy waste.

Applications of Power Transmission Gearboxes

Power transmission gearboxes are versatile and are found in many industries, each with its unique requirements. Below are some key applications:

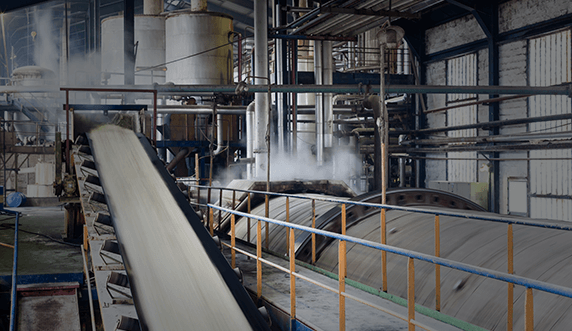

Heavy Industry

In construction, mining, and steel manufacturing, gearboxes are crucial for powering machinery such as crushers, conveyor belts, and heavy-duty drills. These systems require robust gearboxes capable of handling enormous amounts of torque. Power transmission gearboxes provide the required force while ensuring smooth operation even in challenging environments.

Renewable Energy

In the renewable energy sector, gearboxes are essential in systems like wind turbines and solar tracking mechanisms. Wind turbines, for example, rely on gearboxes to convert the slow rotational speed of turbine blades into higher speeds required to generate electricity. Similarly, gearboxes in hydroelectric plants and solar energy systems ensure efficient power conversion and transmission.

Automotive and Aerospace

In the automotive and aerospace industries, gearboxes are used extensively in both primary and auxiliary systems. From vehicle transmissions to helicopter tail rotors, gearboxes are responsible for delivering power efficiently and reliably. Premium industrial gearboxes are essential in these sectors, where performance, precision, and reliability are critical for safety and efficiency.

Material Handling Systems

Power transmission gearboxes are commonly used in material handling systems like conveyors, cranes, and hoists. These applications often require gearboxes that can handle fluctuating loads while maintaining consistent speeds. In factories, warehouses, and ports, these gearboxes enable the smooth and safe movement of goods, ensuring that operations run without disruption.

Power Transmission Gearbox Efficiency: Why It Matters

Minimising Energy Loss

In industrial settings, minimising energy loss is essential for both cost reduction and sustainability. Inefficient gearboxes can lead to significant energy waste, impacting overall system efficiency. Premium gearboxes made with advanced materials and sophisticated design features help reduce friction and heat, maximising the energy transferred to the machinery. This results in less power loss, improved efficiency, and reduced operational costs.

Long-Term Cost Savings and Environmental Benefits

Investing in an energy-efficient gearbox can have significant long-term benefits. Not only does it reduce electricity consumption, but it also lowers the environmental impact of the system. With a premium gearbox, businesses can ensure that their operations are both cost-effective and environmentally responsible, contributing to a more sustainable future.

Choosing the Right Power Transmission Gearbox

Selecting the right gearbox for your system is crucial for maximising performance. Consider the following factors when choosing an industrial or premium gearbox:

Load and Torque Requirements

Each application has specific load and torque requirements that the gearbox must meet. Overestimating or underestimating these requirements can lead to either overloading the gearbox or inefficient energy transfer. A gearbox should be chosen based on the precise power requirements of the machinery it will support.

Speed and Efficiency Considerations

Different systems require different speed ratios and levels of efficiency. For example, automotive transmissions need to operate efficiently at varying speeds, while material handling systems often prioritise torque over speed. Understanding the speed and efficiency requirements of your application is key to selecting the right gearbox.

Environmental Factors

Environmental conditions, such as temperature, moisture, and exposure to chemicals, can affect gearbox performance. Power transmission gearboxes used in industries like mining or food processing need to be durable enough to withstand these challenging conditions.

Cost vs. Performance

While premium gearboxes may come with a higher initial investment, their long-term performance and efficiency make them a more cost-effective option. Balancing cost and performance will ensure that you get the best value for your money while maintaining operational efficiency.

Maintenance of Power Transmission Gearboxes

Routine Inspections

Regular inspections are crucial for avoiding premature gearbox failure. Checking for wear, misalignment, and unusual sounds helps ensure that your industrial gearbox operates efficiently and prevents unexpected downtime.

Lubrication and Cooling

Proper lubrication (oil vs. grease) is essential for reducing friction in power transmission gearboxes. Keeping the gearbox cool prevents overheating, which can lead to performance loss and component damage.

Vibration Analysis

Vibration monitoring helps detect early signs of wear and misalignment in premium gearboxes. Identifying vibrations early can prevent costly repairs and ensure optimal performance.

Troubleshooting Common Issues

Overheating, poor lubrication, and misalignment are common gearbox problems. Ensuring proper maintenance and lubrication can avoid these issues, extending the life of industrial gearboxes and minimising downtime.

How Power Transmission Gearboxes Improve System Performance

Reliability and Durability

A high-quality premium gearbox enhances system reliability and minimises downtime. It ensures consistent performance even under heavy loads, boosting the overall productivity of industrial systems.

Cost-Effectiveness

Investing in industrial gearboxes with higher durability and efficiency reduces maintenance costs and lowers the risk of failures, providing long-term savings for businesses.

Flexibility in Operations

Power transmission gearboxes offer flexibility in adjusting speed, torque, and load. This adaptability helps optimise operations across various industries, improving overall system performance and productivity.

FAQs

What is a power transmission gearbox?

A power transmission gearbox is a mechanical device that transfers rotational power from a motor to machinery, adjusting speed, torque, and direction. It plays a key role in ensuring efficient power transfer in industries like manufacturing, automotive, and renewable energy.

What types of power transmission gearboxes are available?

Common types include helical, bevel, and planetary gearboxes. Each type is designed for specific applications, offering unique advantages like high torque capacity, space efficiency, and customizable designs to meet industry needs in sectors such as automotive, construction, and renewable energy.

Why are premium gearboxes important for industrial applications?

Premium gearboxes offer high efficiency, durability, and reduced energy loss, making them ideal for heavy-duty industrial applications. They help improve system reliability, reduce operational costs, and ensure long-term performance, particularly in sectors like automotive, mining, and manufacturing.

How do I choose the right power transmission gearbox?

To choose the right gearbox, assess factors like load and torque requirements, desired speed, environmental conditions, and efficiency needs. Working with premium gearbox dealers in Hyderabad, Rajasthan, Kerala, Odisha, or Delhi ensures you get a tailored solution for your specific application.

Achieve Optimal Performance with Premium Industrial Gearboxes

Are you looking for high-performance industrial gearboxes or premium gearboxes? Look no further! At Santram Engineers, we are the largest distributor of Premium Transmission gearboxes, offering top-notch solutions for all your power transmission needs. Whether you’re in Hyderabad, Rajasthan, Kerala, Odisha, or Delhi, our expert team is ready to help you find the perfect gearbox to optimise your operations.

Our premium gearboxes are designed for durability, efficiency, and high torque capacity, ensuring your machinery performs at its best. As leading premium gearbox dealers and suppliers, we provide customised solutions tailored to meet the unique demands of various industries, from automotive to renewable energy.

Choose Santram Engineers for reliable, long-lasting power transmission solutions. Contact us today at +91 96247 39393 or email us at sales@santramengineers.com to learn more about our premium products and how we can help boost your operational efficiency. Let us be your trusted partner in powering success!