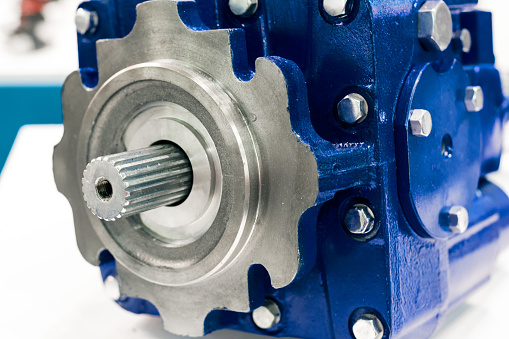

Planetary gearboxes are essential in industries ranging from robotics and conveyors to automotive and construction. Known for their compact design, efficiency, and high torque transmission, these gear systems are vital for precision and heavy-duty operations.

However, selecting the right planetary gearbox is not always straightforward. Businesses often make mistakes that lead to premature failures, increased costs, and production inefficiencies. Whether sourcing from gearbox manufacturers in India or international suppliers, avoiding these mistakes is key to ensuring long-term performance and value.

Below are some of the most common mistakes buyers make when purchasing planetary gearboxes and how to avoid them.

9 Common Mistakes to Avoid When Investing in Planetary Gearboxes

Mistake 1: Ignoring the Specific Application Requirements

One of the most frequent mistakes businesses make is assuming that planetary gearboxes are universally adaptable. While these gear systems are versatile, different applications demand very specific configurations.

- Robotics require high precision and low backlash for smooth, accurate movements.

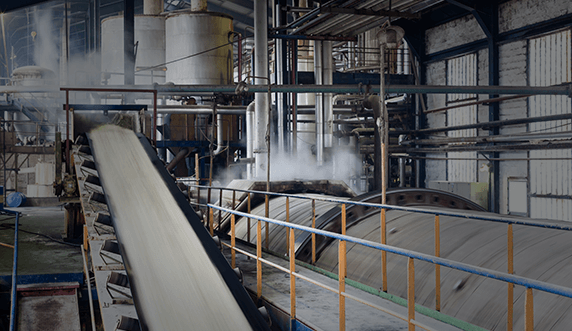

- Conveyors need gearboxes designed for continuous operation with the right torque-to-speed balance.

- Automotive applications focus on compact designs with high torque density to handle demanding loads.

- Construction equipment requires heavy-duty planetary gearboxes capable of handling extreme torque and environmental stresses.

If a buyer simply selects a gearbox based on generic specifications or assumes a “one-size-fits-all” model will work, the result is often premature failure, excessive wear, and reduced efficiency.

How to avoid this mistake:

- Begin with a clear understanding of your machine’s load, torque, speed, and duty cycle requirements.

- Consult with your engineering team to define the exact operational conditions.

- Share these details with a trusted gearbox dealer or supplier, who can match your requirements with the correct product line from leading gearbox manufacturers.

Taking the time to identify application-specific needs ensures that the gearbox you purchase not only fits but also enhances your system’s overall performance.

Mistake 2: Overlooking Supplier Credibility

Another major mistake is underestimating the importance of supplier credibility. With so many gearbox manufacturers and dealers in India and globally, it’s easy to be swayed by low prices or flashy marketing. However, not all suppliers provide reliable products or adequate after-sales support.

A credible supplier is more than a vendor; they are a long-term partner. Reputable gearbox manufacturers and dealers typically provide certified products, maintain a strong industry reputation, and offer technical assistance even after the sale.

Failing to check supplier credibility may leave you with poor-quality gearboxes, limited warranty coverage, or no support when issues arise.

How to avoid this mistake:

- Verify the supplier’s certifications to ensure product quality and compliance with industry standards.

- Research their industry reputation through case studies, references, and client testimonials.

- Choose suppliers who work closely with established gearbox manufacturers and provide dependable after-sales service.

By sourcing from credible suppliers, you reduce risks and secure the reliability your operations depend on.

Mistake 3: Not Considering Gearbox Specifications Carefully

Planetary gearboxes may look similar, but their technical specifications differ significantly. Many buyers either overlook or misunderstand these specifications, resulting in mismatches that cause inefficiencies or system failures.

Some of the most critical specifications include:

- Torque rating: Determines whether the gearbox can handle peak and continuous loads.

- Backlash: Essential for applications requiring precision, such as robotics or CNC machines.

- Efficiency: Affects energy usage and overall system performance.

- Gear ratio: Impacts the torque-speed balance of your system.

- Size and mounting type: Ensures compatibility with your machinery setup.

When these factors are not carefully considered, the consequences can include overheating, mechanical wear, or even a complete gearbox breakdown.

How to avoid this mistake:

- Review the technical datasheets provided by gearbox manufacturers in detail.

- Consult with your supplier to understand how each specification impacts performance in your application.

- Run compatibility checks to ensure the gearbox integrates smoothly into your machinery.

Paying attention to specifications ensures the gearbox is not just functional but optimised for efficiency and reliability.

Mistake 4: Focusing Only on Cost

Cost is often the first factor businesses evaluate, but prioritising the cheapest option is a critical mistake. While low-cost gearboxes may reduce upfront expenses, they often come with hidden long-term costs such as frequent maintenance, unexpected downtime, and shorter service life.

For example, a low-cost gearbox might use lower-grade materials or lack the precision engineering required for demanding applications. This results in inefficiencies and eventual replacement, making the “cheap” choice far more expensive over time.

Instead of only focusing on price, consider the Total Cost of Ownership (TCO), which includes:

- Initial purchase cost

- Installation and integration expenses

- Expected maintenance requirements

- Energy efficiency and operating costs

- Overall lifespan and reliability

How to avoid this mistake:

- Balance cost with quality and durability.

- Assess TCO rather than upfront savings.

- Work with suppliers who offer competitive pricing and dependable after-sales support.

Choosing based on long-term value rather than immediate savings ensures better performance, fewer breakdowns, and stronger ROI.

Mistake 5: Ignoring Maintenance and Support Requirements

Many businesses assume that once a planetary gearbox is installed, it will run smoothly for years without much attention. While planetary gearboxes are indeed durable, they still require periodic maintenance and occasional replacement parts. Ignoring after-sales support and maintenance planning is a costly oversight.

Lack of spare parts availability, unresponsive service teams, or inadequate technical support can lead to prolonged downtime if issues arise. For industries like automotive assembly or heavy construction, even a few hours of unplanned downtime can translate into significant financial losses.

How to avoid this mistake:

- Choose suppliers who have a robust service network and reliable after-sales support.

- Verify that spare parts are readily available to reduce lead time in case of repairs.

- Ask about the supplier’s maintenance guidelines and preventive service plans.

- Partner with gearbox dealers who collaborate closely with established gearbox manufacturers to ensure ongoing support.

Proper maintenance planning doesn’t just prevent breakdowns, it extends the lifespan of your planetary gearboxes and maximises ROI.

Mistake 6: Neglecting Compatibility with Existing Systems

Another common mistake is purchasing planetary gearboxes without confirming compatibility with existing mechanical and electrical systems. Even if the gearbox meets torque and speed requirements, misalignment in size, mounting type, shaft dimensions, or motor interface can lead to major integration challenges.

The result? Unexpected downtime, additional costs for modifications, or, in some cases, complete replacement of the gearbox.

How to avoid this mistake:

- Conduct a full compatibility check before finalising the purchase.

- Confirm mechanical details such as mounting type, shaft alignment, and gearbox size.

- Ensure electrical integration with motor power, drive systems, and control units.

- Work closely with supplier engineers who can verify fit and integration before shipment.

By prioritising compatibility, businesses can avoid delays and ensure a smooth installation process.

Mistake 7: Ignoring Lead Time and Supply Chain Considerations

Lead time is often overlooked when purchasing planetary gearboxes, but it can have a direct impact on production schedules. If you order a gearbox with long manufacturing or shipping lead times, your equipment could remain idle while waiting for the delivery.

Sourcing from suppliers without a proven supply chain increases risks, especially if they rely on overseas shipments with unpredictable delays. This is particularly important for industries with high production demands, where downtime is not an option.

How to avoid this mistake:

- Always confirm lead times with your supplier before placing an order.

- Check if the dealer maintains a stock of commonly used gearbox models.

- Plan procurement in advance for large or customised planetary gearboxes.

- When possible, source from gearbox manufacturers in India or authorised local dealers to minimise delays and ensure faster delivery.

Effective supply chain planning ensures that your production schedule is never compromised.

Mistake 8: Not Evaluating Warranty and Service Agreements

High-value investments like planetary gearboxes should always come with clear warranty and service agreements. Yet many buyers overlook the fine print, only to discover later that their warranty coverage is limited, filled with hidden clauses, or excludes critical services like on-site support.

Without proper warranty and service agreements, businesses may face high repair costs or replacement expenses if the gearbox fails earlier than expected.

How to avoid this mistake:

- Review warranty terms thoroughly before finalising the purchase.

- Ensure the coverage includes both parts and labour.

- Confirm whether on-site support or remote technical assistance is provided.

- Work with suppliers who offer transparent, buyer-friendly terms and can negotiate extended service agreements when necessary.

A clear warranty and dependable service agreement protect your investment and provide peace of mind.

Mistake 9: Choosing Gearbox Capacity Based on Motor Power Instead of Torque Requirement

One of the most technical yet critical mistakes buyers make is selecting gearbox capacity solely based on the motor’s power rating. While motor power is important, it does not accurately reflect the torque requirements of the application.

Planetary gearboxes are designed to handle specific torque loads. If capacity is calculated only from motor power without considering actual torque demands, the gearbox may be undersized or oversized, leading to inefficiencies, overheating, or premature failure.

How to avoid this mistake:

- Always size the gearbox based on torque requirements rather than just motor power.

- Consult torque-speed curves and load data specific to your application.

- Involve supplier engineers to ensure accurate calculations and proper gearbox selection.

- Request application-based recommendations from gearbox manufacturers or dealers.

By focusing on torque requirements, you ensure that the gearbox capacity aligns with operational needs, resulting in better performance and longer service life.

Final Thoughts

By avoiding these mistakes, whether it’s overlooking maintenance, neglecting compatibility, or misjudging gearbox capacity, businesses can save significant costs and prevent operational setbacks.

Planetary gearboxes are long-term investments, and choosing the right supplier is just as important as selecting the right gearbox. Partnering with experienced gearbox dealers who collaborate with trusted gearbox manufacturers in India and abroad ensures access to reliable products, strong after-sales support, and long-term value.

Get Expert Guidance on Planetary Gearboxes for Your Industrial Needs Today

Choosing the right planetary gearbox can make the difference between seamless performance and costly downtime. Don’t leave such a critical decision to guesswork. Our team of experts is here to help you navigate specifications, compatibility, and supplier options, ensuring you get the gearbox that perfectly matches your industrial application.

As the largest distributor and dealer of Premium Transmission Private Limited, a trusted gearbox manufacturer in India and worldwide, Santram Engineers delivers reliable solutions backed by strong after-sales support, ensuring every gearbox is tailored to meet your specific operational needs.

Send us an email to sales@santramengineers.com or call us at +91 96247 39393 and let us guide you toward smarter, more efficient, and long-lasting gearbox investments.