When it comes to driving performance and reliability in heavy-duty industrial applications, planetary gearbox manufacturers know that intelligent design makes all the difference. Whether you’re running a mining operation, a steel plant, or a packaging line, the gearbox at the heart of your machinery must offer exceptional torque density, load handling, and operational efficiency. That’s why top manufacturers invest deeply in precision engineering, using advanced simulation, cutting-edge materials, and time-tested configurations.

Let’s explore some of the core design principles that define today’s high-performance planetary gearboxes.

Engineering Precision Behind Every Planetary Gearbox

Gear Arrangement and Load Sharing Geometry

The hallmark of a planetary gearbox lies in its unique arrangement of gears — the sun gear, planet gears, and ring gear — which enables compactness and efficiency. But the true genius of the design comes from the way it distributes the load.

Planetary gearbox manufacturers carefully position multiple planet gears around the central sun gear, ensuring that the load is shared equally among them. This even distribution prevents premature gear wear and also enhances the unit’s ability to handle higher torque loads without increasing size. Achieving balanced load sharing involves precise alignment, careful selection of gear modules, and ensuring all components maintain strict tolerances during manufacturing.

Equally important is finding the optimal balance between gear ratio and torque transmission efficiency. A higher gear ratio may offer increased torque multiplication, but it can also lead to a drop in overall efficiency if not carefully engineered. Designers must optimise gear diameters, tooth counts, and meshing geometry to maintain high efficiency across a wide operating range.

High Torque Density Through Compact Architecture

One of the key reasons industries prefer planetary gearboxes is their ability to deliver high torque in a compact footprint. This is where the design truly shines. Unlike traditional gear systems, planetary gearboxes spread torque through multiple gear meshes simultaneously, resulting in a much higher torque output for a given size.

To achieve this, planetary gearbox manufacturers focus on optimising the gear module (the ratio of pitch diameter to number of teeth), the centre distance between gears, and the integration of the gearbox housing. A well-integrated housing not only ensures alignment but also contributes to thermal management and overall rigidity.

Every design decision — from the selection of alloy steels to the shape of the gearbox casing — is aimed at increasing torque density without adding bulk. Finite element analysis (FEA) is often employed to simulate stress and deformation under load, allowing engineers to refine the structure for maximum performance and minimal footprint.

Gear Tooth Profile Optimisation

At the heart of any gearbox is the gear tooth, where power is transferred, efficiency is won or lost, and durability is defined. That’s why planetary gearbox manufacturers place a strong emphasis on involute gear profiles, which provide consistent transmission ratios and minimise sliding contact between gears. This reduces friction and wear, ensuring long-term reliability in demanding industrial environments.

But it doesn’t stop there. Fine-tuning the microgeometry of gear teeth, such as applying crowning to slightly curve the tooth surface or tip relief to reduce edge contact, further improves gear meshing. These enhancements promote smoother engagement and help the system compensate for minor misalignments under load.

To perfect these elements, advanced FEA (Finite Element Analysis) simulations are used. This allows engineers to visualise stress distribution across the tooth surface under various load conditions and make design adjustments to eliminate stress concentrations. The result? A quieter, more efficient gearbox with a longer operational life.

Bearing and Shaft Alignment

In planetary gearboxes, proper bearing and shaft alignment is vital for maintaining load balance and reducing internal friction. Depending on the application, manufacturers may use tapered roller bearings for their superior axial and radial load support, or cylindrical roller bearings for high-speed rotation with minimal heat generation.

The alignment of shafts plays a crucial role in ensuring smooth power transmission. Excessive shaft deflection can cause uneven gear wear, vibration, and reduced efficiency. That’s why precision is built into every stage of the design—from housing geometry to the tolerances of shaft fits. Maintaining centre alignment helps the gearbox run smoothly even in continuous-duty environments with variable loads.

Housing and Structural Integrity

A gearbox’s external housing isn’t just a protective shell—it plays an integral role in system performance. Leading planetary gearbox manufacturers design rigid housings that resist deformation and maintain gear alignment even under heavy mechanical loads.

Using FEA, engineers assess stress distribution and vibration patterns to refine the housing design. This helps identify areas where internal reinforcement ribs or cooling fins can be added for additional strength and thermal performance. Vibration damping and thermal control are essential to prevent premature wear and ensure stable operation across temperature variations.

Material Selection as a Design Variable

The choice of materials is more than just a manufacturing decision—it’s a core design variable. Premium planetary gearbox manufacturers use high-grade structural steels for critical load-bearing components and surface-treated alloy steels for gears requiring superior fatigue resistance and wear performance.

Material selection also affects the gearbox’s weight, strength, thermal characteristics, and machining feasibility. Engineers must balance these factors carefully to ensure the gearbox delivers high performance without becoming overly heavy or expensive to produce.

Thermal Management by Design

One of the less visible, yet extremely important, aspects of gearbox design is thermal management. Excess heat generated during operation can lead to lubricant breakdown, increased wear, and ultimately, premature failure. That’s why efficient heat dissipation is a key focus area for top manufacturers.

Planetary gearbox manufacturers achieve this through smart design choices. Increasing the surface area of the gearbox housing, using thermally conductive materials, and incorporating cooling fins help passively disperse heat. Internally, the gearbox is engineered with flow-optimised pathways to ensure that lubricants reach all critical contact points, efficiently absorbing and transferring heat away from moving parts.

Designers must also weigh passive vs. active thermal control strategies. While passive cooling through materials and design is sufficient for many applications, high-load or high-speed environments may require active cooling elements such as forced-air fans or integrated oil circulation systems. Manufacturers take into account operating conditions to tailor the thermal strategy accordingly.

Gearbox Mounting and Alignment Precision

Even the most robust planetary gearbox won’t perform optimally if it’s not mounted correctly. That’s why mounting precision is a critical design consideration. The base and flange design must ensure even load transfer from the gearbox to the foundation or machine frame, avoiding stress concentrations that can lead to misalignment or vibration.

Manufacturers focus on machining accuracy in the mounting surfaces to maintain concentricity and balance. This ensures the gearbox maintains alignment with the driven equipment, reducing stress on bearings and gears. Integration with motors or driven machinery is also carefully considered during design to avoid any mismatch that might compromise performance.

Modular Design Philosophy

In today’s fast-paced industrial environments, flexibility matters. That’s why many planetary gearbox manufacturers now adopt a modular design approach.

Modular gearboxes feature interchangeable components, such as gear stages, shafts, and housings. This makes it easier to customise gearboxes for specific applications or scale performance based on operational needs. However, the challenge lies in maintaining tight tolerances and mechanical integrity across configurations.

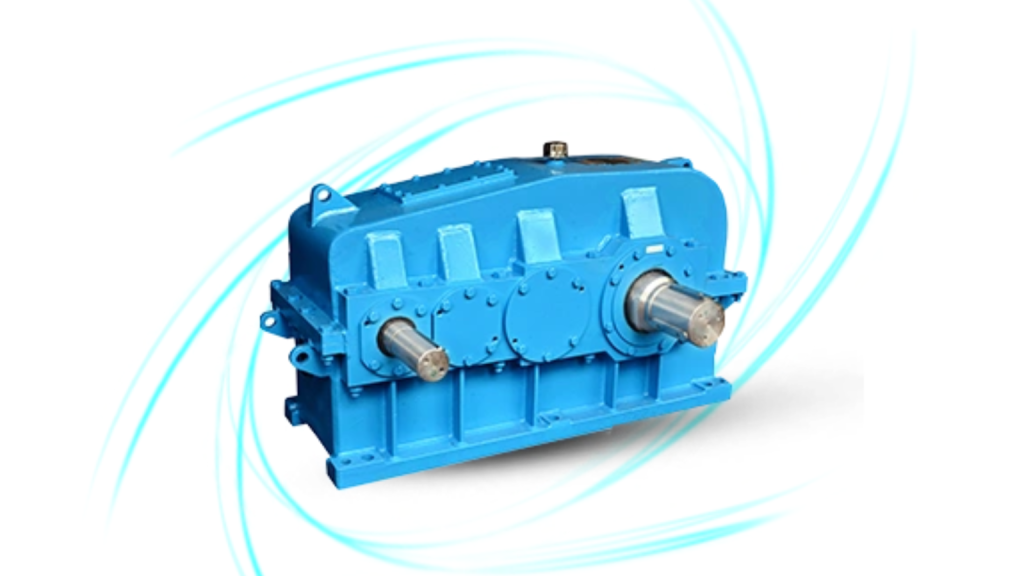

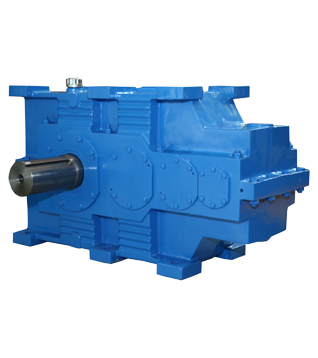

Partner with Santram Engineers for Design-Driven Industrial Gearbox Solutions

When precision, performance, and reliability are essential, Santram Engineers brings you proven solutions backed by Premium Transmission Private Limited, one of India’s most trusted planetary gearbox manufacturers. As a leading distributor and supplier, we offer expertly selected gearboxes designed for demanding industrial applications—ensuring optimal load handling, efficiency, and operational longevity.

With decades of application knowledge and industry experience, Santram Engineers goes beyond supply—we provide engineering guidance, selection support, and after-sales service to ensure the right gearbox powers your success. From seamless integration to high torque density, we help you implement gearbox solutions that work reliably and efficiently in the real world.

Get in touch to find the right industrial gearbox for your needs or to request a customised solution tailored to your application. Contact us at +91 96247 39393 or email us at sales@santramengineers.com to learn more about our products. We will be happy to assist you in making an informed investment.